You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ETS 3.5" Top mount powder coated all black.

- Thread starter Andrade08

- Start date

Maxx Mazda

Contributor

- :

- Stock P5

I'm air force so lets talk planes. the sr71 flew at 80-85thousand feet do you and to take a guess what the ambient temperature is at that altitude? The J58s used on the sr71 atomized and injested so much air to cool the aircraft that air temps were negative degrees..not to be an ass but totally irrelevant argument.

For an "air force" guy (I'm a pilot by the way) you don't seem to grasp the concept of speed and friction very well... The SR-71 flew of speeds around Mach 2.8-3.1 at 85,000'ASL. We know that on a standard day, air cools 2*C per thousand feet. So at FL850 we're looking at a temp of -155*C. Now at a speed of Mach 3, it doesn't matter. The friction of the air around the fuselage gets SO hot at that velocity, that the plane actually expands because of it. (You'll remember that the SR71 leaks fuel while on the ground because it hasn't yet expanded to seal itself. - But you already knew that I'm sure.) Even the Concorde which flew at a lowely 2 times the speed of sound in comparison stretched an average of 7 inches in flight due to the intense heat created. Even on a commercial jet, like a 767 for example flying at a measly M.78 will make the temperature of the air around it (TAT or total air temperature) rise up to 25*C over the still air temperature (SAT.)

So back to what you said, INSANE cooling was required on the aircraft, yes, but the temps of the aircraft were never even close to "freezing" even with sufficient cooling. The SR-71 didn't really need stealth, it flew higher and faster than any enemy radar or SAM's could even fathom of reaching, and I'll have to do more research to determine exactly why it was painted black, but I doubt it had anything to do with temperature...

WoW. you sir are a mojor TOOL. everyone else in this thread has the common sense that when you paint any metal surface it gets insulated.negligable difference, so that means there is one? so does that also mean that the more boost and hot air you put thru that thing will change negligable to significant? why buy something truely 100% performance oriented and take away a percentage from it for visual stimulation?. im not going to argue with you.....i'll make it easy, im going to tell you the same thing i use to tell my ex wife.....you win.

You don't seem to understand, the difference is SO SMALL that it basically wouldn't matter either way. I doubt you'd see a 0.1*C difference between a painted intercooler and a bare aluminum one.

ahh guys cmon, calm it down. First of all we have debated this topic MANY times already (please use that search function). The jury is still out on the actual differences (no one has dyno's to prove it). My personal opinion is that black indeed will make a difference, but it may be so small that you wouldnt notice it without the use of a dyno.

zoomspeed3zoom

Member

I like how the discussion went from the tmic to spelling. Anyone know who won this year's Scripps National Spelling Bee? Seriously though, its annoying but to post responses to someone's spelling imo is even more annoying.

- :

- 2007 MS3

noobz, firefox has it built in!

Some of us are using work computers and can't install whatever we want.

here is the book that talked about the paint and the a-12/sr-71 and cooling of the planes components was supplied by the fuel of the plane. the paint was just for surface temps you'll notice on the a=12 only the leading edges were painted black. Skunk Works: A Personal Memoir of My Years of Lockheed by Ben R Rich. sorry to have got this thred so far off topic with useless info. as for the tmic it looks neat adds to an ofen hood stelthness.

Maxx Mazda

Contributor

- :

- Stock P5

ahh guys cmon, calm it down. First of all we have debated this topic MANY times already (please use that search function). The jury is still out on the actual differences (no one has dyno's to prove it). My personal opinion is that black indeed will make a difference, but it may be so small that you wouldnt notice it without the use of a dyno.

That's what I've been saying! My radiator has a big red "PWR" logo painted on it, so that means it cools less? I don't think so... Like I said form the beginning, the difference in effectiveness, even if the sonbitch was COMPLETELY coated, it would make such a little difference... If you goated it with heat insulating momo foam, sure, but it's not like powdercoating or paint even is gonna "retain" heat...

That's what I've been saying! My radiator has a big red "PWR" logo painted on it, so that means it cools less? I don't think so... Like I said form the beginning, the difference in effectiveness, even if the sonbitch was COMPLETELY coated, it would make such a little difference... If you goated it with heat insulating momo foam, sure, but it's not like powdercoating or paint even is gonna "retain" heat...

well if you look at the scientific principle behind it, black painted material will retain more energy than the uncoated original, whether it is energy from the sun or heat from the engine, energy is energy. But i will agree, the difference is most likely negligible on this scale.

Well i have never come across black intercooler in my life,this must be a first However i believe that colour has no effect on conduction or convection of heat so you should be fine.However radiation is another matter.I would have gone with body color and matching hoses

However i believe that colour has no effect on conduction or convection of heat so you should be fine.However radiation is another matter.I would have gone with body color and matching hoses

well if you look at the scientific principle behind it, black painted material will retain more energy than the uncoated original, whether it is energy from the sun or heat from the engine, energy is energy.

What the H does that mean and how is it relevant to the heat transferred from the hot air passing through the intercooler to the cooler air passing across the intercooler? I call bulls***. We are not talking about transfer of heat by radiation, just direct hot air to aluminum to cooler air conduction.

Paint is just another layer through which heat must pass. Copper/brass radiators are painted because they corrode otherwise. Copper also has several times the thermal conductivity of aluminum and can afford the reduction in thermal performance. Most but not all aluminum alloys are sealed by their own oxide layer and do not need to be painted.

If you want to buy a high performance intercooler and then paint it to be pretty, you are certainly within your rights. Just don't think you are not decreasing the heat transfer capacity, because you are.

-enganear

What the H does that mean and how is it relevant to the heat transferred from the hot air passing through the intercooler to the cooler air passing across the intercooler? I call bulls***. We are not talking about transfer of heat by radiation, just direct hot air to aluminum to cooler air conduction.

I guess I was referring more to the problem of heat soak, and someone mentioned that painting this would only cause a problem if it was exposed to the sun, so I was trying to point out they are wrong.

Paint is just another layer through which heat must pass. Copper/brass radiators are painted because they corrode otherwise. Copper also has several times the thermal conductivity of aluminum and can afford the reduction in thermal performance. Most but not all aluminum alloys are sealed by their own oxide layer and do not need to be painted.

If you want to buy a high performance intercooler and then paint it to be pretty, you are certainly within your rights. Just don't think you are not decreasing the heat transfer capacity, because you are.

-enganear

i agree with this completely, any addition to the metal will have a negative effect on the ability of the IC to dissipate heat, whether its paint, powdercoat, whatever...but I really dont know how much of an effect a painted IC will have at this scale. I would very much be interested to see some numbers to back this up, or maybe even prove me wrong. I contacted protegegarage about this, but the answer I got was not what I was looking for...

funkyman said:Well i have never come across black intercooler in my life,this must be a firstHowever i believe that colour has no effect on conduction or convection of heat so you should be fine.However radiation is another matter.I would have gone with body color and matching hoses

jbiird317 said:i agree with this completely, any addition to the metal will have a negative effect on the ability of the IC to dissipate heat, whether its paint, powdercoat, whatever...but I really dont know how much of an effect a painted IC will have at this scale. I would very much be interested to see some numbers to back this up, or maybe even prove me wrong. I contacted protegegarage about this, but the answer I got was not what I was looking for...

I happened to be reading this during my lunch break and while it was fresh on my mind I took a walk outside and confirmed my belief.

We have a fleet of trucks equipped with Detroit series 60 engines and they vary between Kenworth T-600s, T-2000s, and Frieghtliner Columbias. Albeit the application is a little different, the charge air coolers (and radiators) on the Kenworths are painted entirely black. The paint does chip away quite a bit... The Freightliners have a plain aluminum finish.

But between the Freightliner's and Kenworth's (equipped with the same 14L DDECIV version of the engine) they maintain almost exactly the same boost pressure and heat level when geared the same and operating properly. If I find time I'll go find the test reports we made when we purchased the units.

The thing to keep in mind is that these are turbo diesel vehicles, air-to-air and front mounted as opposed to our top mount, and I guess those arguments could be made.. but just I'm offering the example that on a larger scale application (14L/6cyl) the same engine showed no difference in performance between the painted and not painted versions.

Attachments

Last edited:

Maxx Mazda

Contributor

- :

- Stock P5

...the same engine showed no difference in performance between the painted and not painted versions.

Wicked info. Are you a HD mechanic?

Wicked info. Are you a HD mechanic?

Technically no. I work in a diesel shop. I have an advanced knowledge of the mechanics. I am more on the diagnostic end as a "Maintenance Operator". We have around 250 power units on the road across the country and about 400 trailers. If and when something breaks, I'm the guy to call. I find somewhere to get it fixed, argue the price/logistics of getting it done, and get it on the road with minimal downtime.. haha. It's a fun job, to be honest, and I love that I found something where I can use my college education (i.e. not entirely blue collar) and love of big loud machines in the same place.

Okay, about three years ago we did a comparative test between the last of the KW's to carry the Series 60 engine before Mr. Penskee bought Detroit and they became Freightliner-exclusive. We lined up a brand new T-2 and Columbia same engine and did a series of tests (dyno included) between the two (air cooler color was not something on my mind at the time lol).

I can't find that paperwork. Sadly.

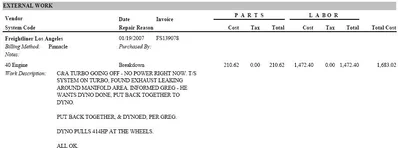

What I did come up with are some copies of service paperwork within the last year of vendors running our units on dynos. The two examples I'm providing are vendors performing dyno runs on one Freightliner and one Kenworth T-2000 with 550,000 miles on each of them. Both were recently serviced (within a month). Both are equipped with the same gearset, trans (Eaton-Fuller 10sp Lightning Top-2) and diff. Both with the same ECU parameters; running 22.5psi boost.

We deem 15% power variation to be within the norm. These are two of our more meticulously maintained units, however, and when they went into the shop for power loss we decided it was best to have them tested on the dynos.

The Kenworth, with it's black charge air cooler, runs 410hp at the wheels and the Freightliner, with the aluminum, runs 414hp. The KW was done at a Detroit dealer and the Freightliner at a Freightliner dealer. A 4HP deviation is remarkably small considering the multitude of things that can affect a truck's power level. I did pick these two examples, in particular, because of their similar attributes, however, with the number of other things that could affect the power rating, it is close enough that I would say the HP ratings are "the same".

Lastly, when we ran our test, every temperature we could come up with, related to the turbo, ran within 5 degrees of each other, throughout the duration of the test. The tests were computer controlled with self logging ACER sensors.

Given this information, I think the biggest thing left to figure out is whether the IC being front mount instead of top makes a big difference.

I can't find that paperwork. Sadly.

What I did come up with are some copies of service paperwork within the last year of vendors running our units on dynos. The two examples I'm providing are vendors performing dyno runs on one Freightliner and one Kenworth T-2000 with 550,000 miles on each of them. Both were recently serviced (within a month). Both are equipped with the same gearset, trans (Eaton-Fuller 10sp Lightning Top-2) and diff. Both with the same ECU parameters; running 22.5psi boost.

We deem 15% power variation to be within the norm. These are two of our more meticulously maintained units, however, and when they went into the shop for power loss we decided it was best to have them tested on the dynos.

The Kenworth, with it's black charge air cooler, runs 410hp at the wheels and the Freightliner, with the aluminum, runs 414hp. The KW was done at a Detroit dealer and the Freightliner at a Freightliner dealer. A 4HP deviation is remarkably small considering the multitude of things that can affect a truck's power level. I did pick these two examples, in particular, because of their similar attributes, however, with the number of other things that could affect the power rating, it is close enough that I would say the HP ratings are "the same".

Lastly, when we ran our test, every temperature we could come up with, related to the turbo, ran within 5 degrees of each other, throughout the duration of the test. The tests were computer controlled with self logging ACER sensors.

Given this information, I think the biggest thing left to figure out is whether the IC being front mount instead of top makes a big difference.

Attachments

Last edited:

I will repeat it differently .It is scientifical fact and no room for argument that colour has no effect on conduction or convection of heat so you should be fine.However radiation is another matter.Radiation meaning light.I think that as a theme you should have gone with body colour or if the theme were to be red like red calipers hoses,struts then red would have been a good choice but black looks cool too.

Last edited:

I happened to be reading this during my lunch break and while it was fresh on my mind I took a walk outside and confirmed my belief.

We have a fleet of trucks equipped with Detroit series 60 engines and they vary between Kenworth T-600s, T-2000s, and Frieghtliner Columbias. Albeit the application is a little different, the charge air coolers (and radiators) on the Kenworths are painted entirely black. The paint does chip away quite a bit... The Freightliners have a plain aluminum finish.

But between the Freightliner's and Kenworth's (equipped with the same 14L DDECIV version of the engine) they maintain almost exactly the same boost pressure and heat level when geared the same and operating properly. If I find time I'll go find the test reports we made when we purchased the units.

The thing to keep in mind is that these are turbo diesel vehicles, air-to-air and front mounted as opposed to our top mount, and I guess those arguments could be made.. but just I'm offering the example that on a larger scale application (14L/6cyl) the same engine showed no difference in performance between the painted and not painted versions.

What is in the picture? That can't be a charge cooler in the front, its only like an inch thick and has a tiny line going to it. It looks like a cooler for an Allison transmission. Is the second heat exchanger the charge cooler? Is it aluminum or tinned copper? Boost pressure is not a direct function of intercooler efficiency, but horsepower is. I used to be a product engineer for Volvo, big trucks are fun!

-enganear

The fact is anything on top of it is going to retain the radiant heat... it's a matter to what extent. More important than ANY color is the thickness of the material applied.

I get the feeling the charge air cooler on my trucks are painted to prevent the look of corrosion that occurs... I would look into a ceramic coating (which could actually dissipate radiant heat more effectively) if I were deadset on coving my intercooler with anything.

I get the feeling the charge air cooler on my trucks are painted to prevent the look of corrosion that occurs... I would look into a ceramic coating (which could actually dissipate radiant heat more effectively) if I were deadset on coving my intercooler with anything.

What is in the picture? That can't be a charge cooler in the front, its only like an inch thick and has a tiny line going to it. It looks like a cooler for an Allison transmission. Is the second heat exchanger the charge cooler? Is it aluminum or tinned copper? Boost pressure is not a direct function of intercooler efficiency, but horsepower is. I used to be a product engineer for Volvo, big trucks are fun!

-enganear

Trans cooler, charge air, radiator (can't see the radiator)- in that order. I couldn't get a decent picture of it without standing in the hood and I didn't think anyone would pick out the difference. haha so kudos. It's an aluminum cooler. And yes. Big trucks are very fun. The dairy company I worked for before this ran some Volvos. We used the bust up the suspensions all the time hauling milk in the reefer trailers.

Last edited:

New Posts and Comments

- Replies

- 0

- Views

- 15

- Replies

- 299

- Views

- 58K

- Replies

- 1

- Views

- 174

- Replies

- 16

- Views

- 8K