You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

iracemine's purpose built N/A ST2 thread

- Thread starter iracemine

- Start date

Installshield 2

Gothenburg Superiority

yeah, did you mess with the throttle by-pass screw (small phillips head on top of the TB; firewall side), or the throttle plate stop screw?...which is the kind of bolt looking thing on the throttle plate/cable linkage...also firewall side...not a big deal in either case, since you can control your TPS output with the microtech...but it'll help diagnose the issue...

What is controlling your IAC valve? The microtech, or the stock ecu?...Mine too wouldn't idle after warmed up (would just stall immediately on throttle lift after warm), and the small screw on top helped tremendously after i backed it out a good few turns...Start the car cold, let it idle for 15 seconds or so...then try backing that out a little more with the engine running...when you hear the intake noise start to change pitch slightly (it'll sound like a hiss coming from the filter area), you're getting somewhere...small adjustments before i heard that noise did nothing...but after i got brave and let it out a little more i haven't stalled since...i later checked and found that the screw would still need a 8 or so full turns to completely come out, so its still safely engaged...

if your stock ecu is controlling the IAC, this will not change idle rpm...it just changes the incremental stepping the IAC is given under deceleration (but not exactly positive what that is being read off of)...if the microtech is somehow controlling it (not even sure how you'd do that haha), it might bounce your idle rpm all over the place...the stock ecu controls idle with the IAC's predetermined set position...which the ecu will use as 'fully opened', as in it'll never open more than that without jumping the diagnostics box during adjustment...that screw controls a bleed-through port in which air can move around the IAC (its there for higher mileage engines that may not be making ideal vacuum at idle, but are not quite ready for a full rebuild)...in our case, with kind of gnarly cams, the intake vacuum at idle isn't enough to fully prevent intake reversion once warm...and opening that port via the screw lets more air in no matter what the IAC does...however, the IAC will be given new parameters when it sees your idle is too high, and that 'fully opened' parameter i mentioned above is dropped down a step or two...

end result...your engine will idle fine when hot (fine as in lumpy as hell, but no stalling)...at the same rpm as before...but, a lot of this is dependent on how your stuff is wired...so, sorry for the long post if it doesn't apply to you haha...

What is controlling your IAC valve? The microtech, or the stock ecu?...Mine too wouldn't idle after warmed up (would just stall immediately on throttle lift after warm), and the small screw on top helped tremendously after i backed it out a good few turns...Start the car cold, let it idle for 15 seconds or so...then try backing that out a little more with the engine running...when you hear the intake noise start to change pitch slightly (it'll sound like a hiss coming from the filter area), you're getting somewhere...small adjustments before i heard that noise did nothing...but after i got brave and let it out a little more i haven't stalled since...i later checked and found that the screw would still need a 8 or so full turns to completely come out, so its still safely engaged...

if your stock ecu is controlling the IAC, this will not change idle rpm...it just changes the incremental stepping the IAC is given under deceleration (but not exactly positive what that is being read off of)...if the microtech is somehow controlling it (not even sure how you'd do that haha), it might bounce your idle rpm all over the place...the stock ecu controls idle with the IAC's predetermined set position...which the ecu will use as 'fully opened', as in it'll never open more than that without jumping the diagnostics box during adjustment...that screw controls a bleed-through port in which air can move around the IAC (its there for higher mileage engines that may not be making ideal vacuum at idle, but are not quite ready for a full rebuild)...in our case, with kind of gnarly cams, the intake vacuum at idle isn't enough to fully prevent intake reversion once warm...and opening that port via the screw lets more air in no matter what the IAC does...however, the IAC will be given new parameters when it sees your idle is too high, and that 'fully opened' parameter i mentioned above is dropped down a step or two...

end result...your engine will idle fine when hot (fine as in lumpy as hell, but no stalling)...at the same rpm as before...but, a lot of this is dependent on how your stuff is wired...so, sorry for the long post if it doesn't apply to you haha...

Last edited:

Sheesh. Loppy as hell is right. I have solid mounts and I think the paint is going to vibrate off the car. No stall but it goes from 800 to like 2K. However if I reset the stock ECU (controls the iac) after a CEL event the car idles slightly loppy. Or kinda cool loppy. But as soon as the car gets driven or run a bit the CEL comes back on and then the idle goes to shijt again. I need to figure out why the CEL comes on. And I am sure the idle will be fine.

I am also fine with the car idling higher too. But first things first. Let me try to diagnose the CEL.

Post race/build vid to come soon. After that I will post the 4banger lope vid from hell.

I am also fine with the car idling higher too. But first things first. Let me try to diagnose the CEL.

Post race/build vid to come soon. After that I will post the 4banger lope vid from hell.

Installshield 2

Gothenburg Superiority

Well all my experience with kind of similar cams is simply with a mp3 ecu so far...and since i'm not sure how all this is wired for you, it may not be exactly the same...but this is what is happening in my case, some of which probably applies to you...

the geometry of the FS makes some pretty silly air speeds even at idle...since the stock ecu is mostly controlling your IAC valve, its 'mostly' controlling idle...the grey area being how ignition timing is controlled, which the stock ecu will adjust on the fly at idle to keep it settled...i've read a lot of people saying its very tough to tune this area on the microtech's, and that bumping idle rpm is a safe work around...

either way...idle quality is EXTREMELY sensitive to the intake cams timing...especially when the intake cam is fairly aggressive...i can swing my exhaust cam all over the place and little to anything changes with idle lope or quality...or even stalling...but just 2 degree changes on the intake and it can go from acceptable...to undriveable...instantly...

your engine light is probably getting tripped from a p0300 code, or random multiple cylinder misfire...the stock ecu monitors this type of event from distance...its not a very precise code, its just something that can be caused by a large number of factors...in our case...i'm 90% sure its just the lopey idle...one parameter the stock ecu watches is rpm deviation with fixed throttle input...idle IS fixed throttle input; the tps isn't going anywhere...but the ecu will sit there constantly changing the ignition, and still see the rpm deviating more than 250 rpm...

in my case, using torque pro on my android phone...after a code reset...i first get a yellow 'pending' code after the first few hours of driving...pending codes will not trip the dash light, but are stored in the system and continue to be observed as a potential threat...after about 1000 miles...it converts from pending to a fully displayed issue, and the light comes on...more important that mileage, its more related to how many times the engine is started...i've never had the code pop up while cruising...its only shows up while idling or traffic, especially when the engine is only partially warm...

i'm very limited with my ecu on options to beat this...i haven't found a way to fully prevent it from ever coming back...but, intake cam adjustments make all the difference on how often its displayed...the main problem with this is that the adjustments may not be ideal for peak power...so i'm kind of stuck until i finally upgrade to a stand alone...i'd have to look under the hood to see what exact cam timing i have, but I remember retarding intake timing about 2 degrees from nuetral which immensely helped with this...and according to my logs can still get nearly 140whp...I was hitting about 143whp max, but was popping that code nearly every time the engine was started...so its clear, in my case, that the adjustments made to combat the code frequency are not ideal for higher end peak hp...so you might be stuck with a trade off unless you look in to a different way to control that iac and idle altogether...and not let the stock ecu throw any codes of any kind...

i guess i should've asked first...is this is a code related to the stock ecu, or is this something completely separate related to the microtech?

the geometry of the FS makes some pretty silly air speeds even at idle...since the stock ecu is mostly controlling your IAC valve, its 'mostly' controlling idle...the grey area being how ignition timing is controlled, which the stock ecu will adjust on the fly at idle to keep it settled...i've read a lot of people saying its very tough to tune this area on the microtech's, and that bumping idle rpm is a safe work around...

either way...idle quality is EXTREMELY sensitive to the intake cams timing...especially when the intake cam is fairly aggressive...i can swing my exhaust cam all over the place and little to anything changes with idle lope or quality...or even stalling...but just 2 degree changes on the intake and it can go from acceptable...to undriveable...instantly...

your engine light is probably getting tripped from a p0300 code, or random multiple cylinder misfire...the stock ecu monitors this type of event from distance...its not a very precise code, its just something that can be caused by a large number of factors...in our case...i'm 90% sure its just the lopey idle...one parameter the stock ecu watches is rpm deviation with fixed throttle input...idle IS fixed throttle input; the tps isn't going anywhere...but the ecu will sit there constantly changing the ignition, and still see the rpm deviating more than 250 rpm...

in my case, using torque pro on my android phone...after a code reset...i first get a yellow 'pending' code after the first few hours of driving...pending codes will not trip the dash light, but are stored in the system and continue to be observed as a potential threat...after about 1000 miles...it converts from pending to a fully displayed issue, and the light comes on...more important that mileage, its more related to how many times the engine is started...i've never had the code pop up while cruising...its only shows up while idling or traffic, especially when the engine is only partially warm...

i'm very limited with my ecu on options to beat this...i haven't found a way to fully prevent it from ever coming back...but, intake cam adjustments make all the difference on how often its displayed...the main problem with this is that the adjustments may not be ideal for peak power...so i'm kind of stuck until i finally upgrade to a stand alone...i'd have to look under the hood to see what exact cam timing i have, but I remember retarding intake timing about 2 degrees from nuetral which immensely helped with this...and according to my logs can still get nearly 140whp...I was hitting about 143whp max, but was popping that code nearly every time the engine was started...so its clear, in my case, that the adjustments made to combat the code frequency are not ideal for higher end peak hp...so you might be stuck with a trade off unless you look in to a different way to control that iac and idle altogether...and not let the stock ecu throw any codes of any kind...

i guess i should've asked first...is this is a code related to the stock ecu, or is this something completely separate related to the microtech?

Last edited:

I have the motor out again at the moment, but I wanted to do some more testing. After resetting the ecu the motor will idle fine. When the cel comes on then the idle will lope terrible. But again only when the car will warm up. I want to figure that out. I did solder in a 1.5K resistor in place of the air intake sensor for the stock ecu. Cant believe that would do that but again there is way to many variables at this point. When I get all this other non motor related stuff done I will be back at making the motor more reliable.

OK motor is back in and the terrible idle was still there. I now backed out the IAC screw all they way, and it slightly helped. So I jumped the ten and gnd in the diagnostic box and raised the idle to 1000. It will lope between 1000 and 1400. Its not bad at all now. It does not shake the car to death anymore. However when I pull the jumper out of the diagnostic box the idle goes back down to where it was. So do I need to keep this jumper in there all the time?????

could not justify making another build thread so I just am going to put some crap in here too.

could not justify making another build thread so I just am going to put some crap in here too.

Attachments

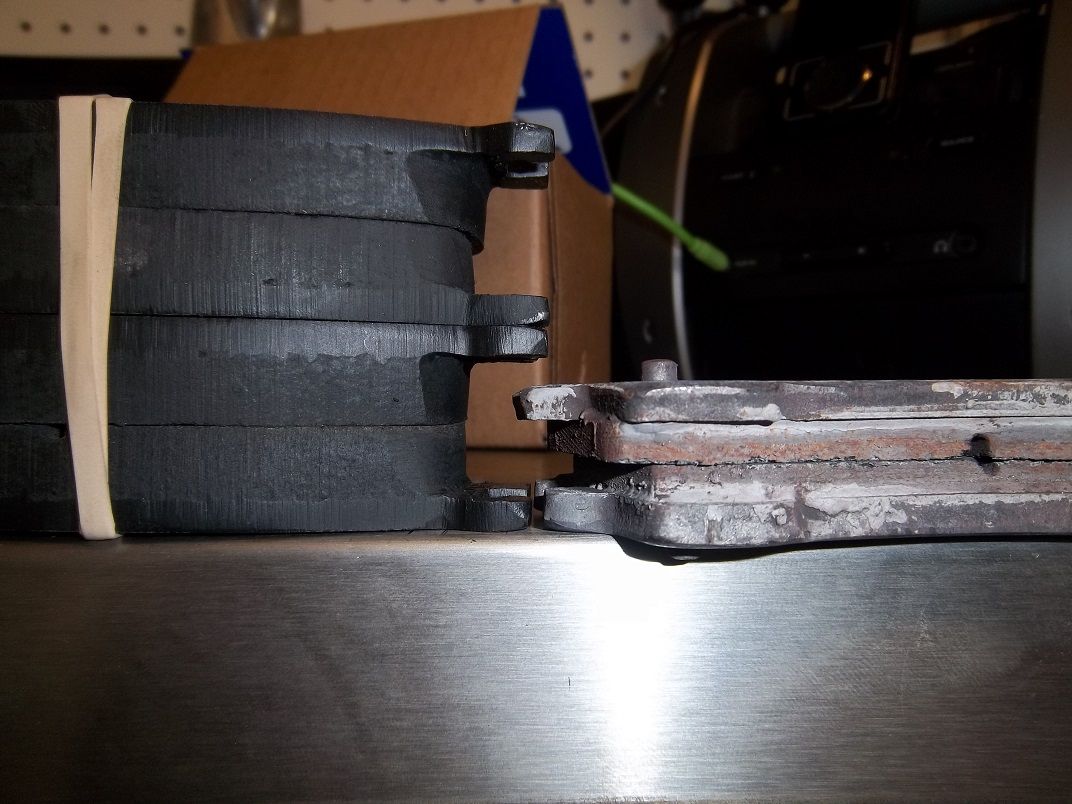

wildwood. 1" tandem with a proportioning valve inside the cockpit. Finally have SS brake lines front and rear.

The 1" don't work. Going to try out the 7/8" next. If I am right this cars pedal gives about a 6 to 1 pedal ratio and with the 7/8 it should give about 1000psi to the calipers.

Keeping in the jump wire. It works and starts better with it in.

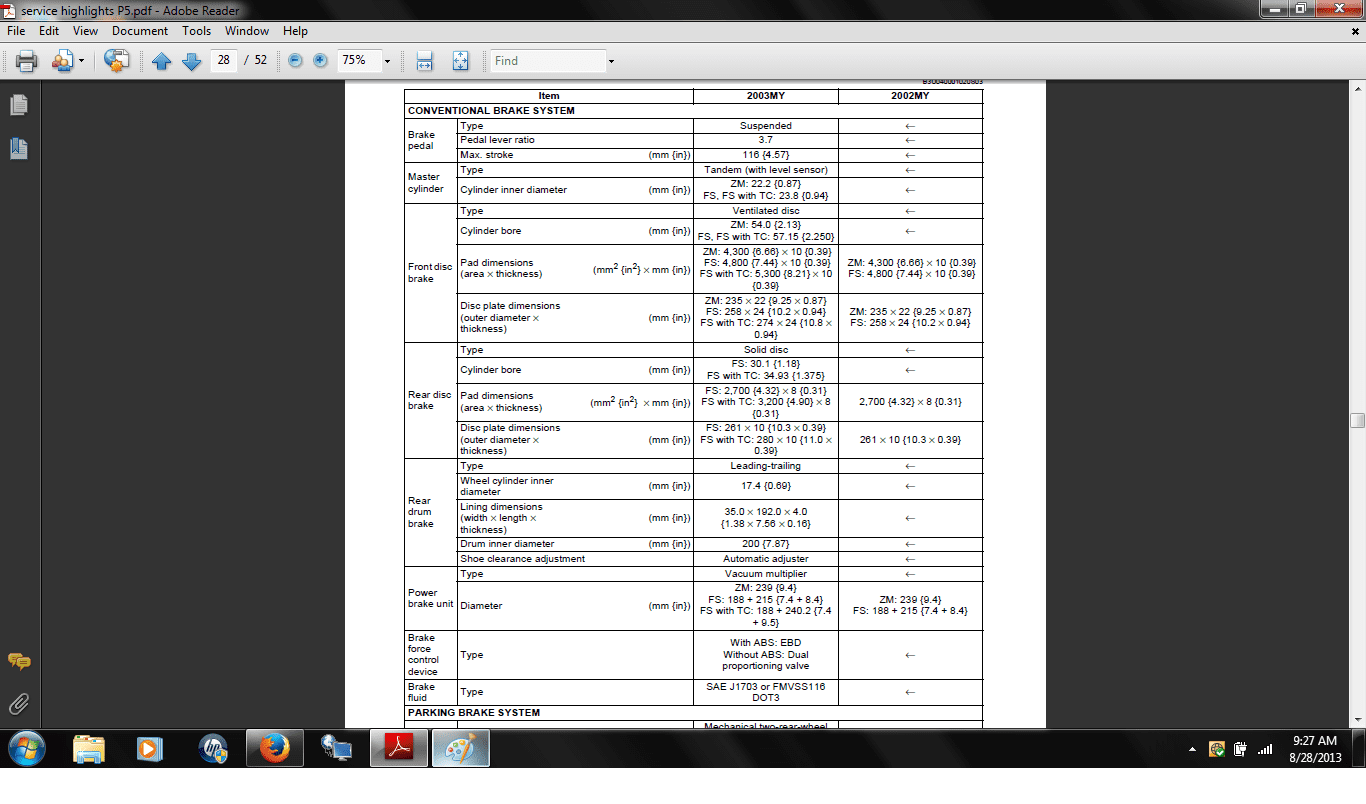

Foud this on the P5 brakes. It says that the pedal ratio is 3.7?

So then I found this guys calculator and it says that 7/8 is correct to get to 1000PSI witch is what the above thing says that this car needs.

http://www.markwilliams.com/braketech.aspx

So then I found this guys calculator and it says that 7/8 is correct to get to 1000PSI witch is what the above thing says that this car needs.

http://www.markwilliams.com/braketech.aspx

Attachments

Don't think the 7/8 is quite there. I also drilled a new hole in the brake arm about 1/8" higher and its there but not perfect. So I think I will buy the 3/4, and that's against the recommendations of wilwood. They say that my car will get above 1200psi and that will start to flex the calipers and what not. But I think that I was saying that this car is 6 to 1 ratio. But its not. Stock is 3.7. I will do the math and find out what it is after I raised the fulcrum. And take some pics.

Edit: With the second hole it's now at about 3.97. With the 3/4 MC it should put me at about 135lbs of force to get 1200psi out if the brakes. That is with in the "recommended foot pedal force range" from that web page. As it is now with the 7/8 I am at 185. Just 10lbs out of their recommended range. At this point I don't think anyone is reading this anymore so here are some more pretty pictures.

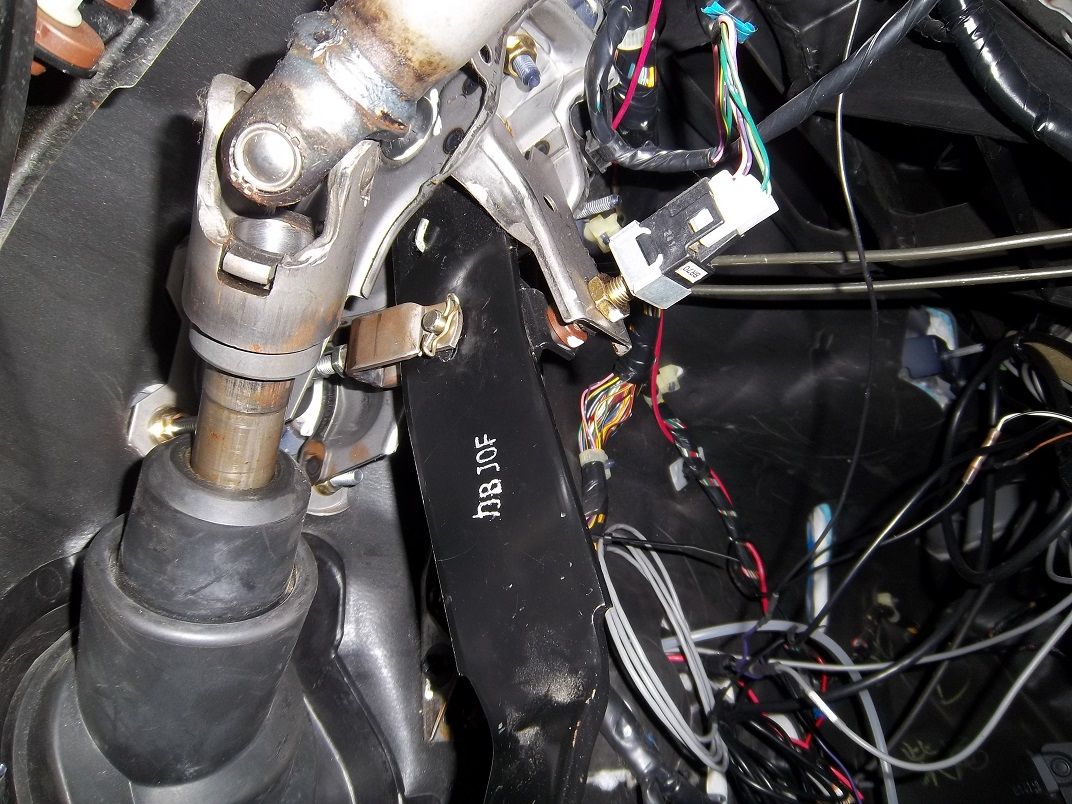

The hole just above the other one. Higher than that it would bind.

Centric MC.

Great use of a wasted space (I thought)

Edit: With the second hole it's now at about 3.97. With the 3/4 MC it should put me at about 135lbs of force to get 1200psi out if the brakes. That is with in the "recommended foot pedal force range" from that web page. As it is now with the 7/8 I am at 185. Just 10lbs out of their recommended range. At this point I don't think anyone is reading this anymore so here are some more pretty pictures.

The hole just above the other one. Higher than that it would bind.

Centric MC.

Great use of a wasted space (I thought)

Attachments

Last edited:

Installshield 2

Gothenburg Superiority

out of curiosity, what kind of oil pressures are you getting?...and i forget, how did you mount the sensors?

out of curiosity, what kind of oil pressures are you getting?...and i forget, how did you mount the sensors?

With the new idle 30 to 80. What sensors??

OK test drove the third MC and it looks like the 3/4" with tandem reservoirs is the ticket. After the second race/shakedown of the season I should be able to dial in the rear brake bias knob perfectly and report back. Hopefully the gopro works great and I can post up a good vid of Gingerman.

After that... and I can find the cash I will tune the car one more time and check in with my results in the N/A dyno race thread. S it looks like this thread is coming to a close. THANK YOU people for the help. I will try and help you guys as much as I can too on your threads. Cheers!

After that... and I can find the cash I will tune the car one more time and check in with my results in the N/A dyno race thread. S it looks like this thread is coming to a close. THANK YOU people for the help. I will try and help you guys as much as I can too on your threads. Cheers!

Season ended for me before the season ended. The 3/4 MC is the perfect ratio with the stock 3.7 brake pedal. However and a BIG however it moves only the tiniest bit of fluid. Since this is only a $15K car everything on it is cheap so there is some flex and movement, and the brake calipers suffer from this thing called piston knockback/kickback. Kickback is when the calipers get knocked by the rotor pushing brake fluid back into the MC's reservoir. So just like after you do a brake job you need to pump the pedal a time or two to push the pads up against the rotors. After installing this smaller MC I now have to do that before every corner. Some times not even a half a pump others its almost more than one pump. Not that big of a deal, but if I forget to do that "brake check" I would go flying off the track. Thank god it was not me slamming into my competitors trunk.

<iframe width="420" height="315" src="//www.youtube.com/embed/cUdJmBH_krA?rel=0" frameborder="0" allowfullscreen></iframe>

So the whole reason I went this route is to get a consistent pedal. I thought it was due only because of the lack of vacuum with these huge cams installed. Well turns out that was only half the problem (or third if you wanted to install stiffer suspension components that would have to be one off or some sort of retro fit). Our MC is much larger at about 1". This MC pushes so much fluid that it masks the knockback that naturally occurs in street cars. However racing at the "line" any inconstancy will mean square tires or loosing a place in the race. However to move that much fluid you would need the booster, the thing I can't rely on any more.

So me being the cheap ass I tried the 2lbs and 10lbs line residual pressure valves. They don't work for s***. The second anything comes up over 10lbs it just blows by the valve. So I tried the anti knockback springs... Nope. To get this car to brake even more consistent I am thinking I will need to surpass the 1" and go to somewhere around the 1 1/8" area. However with the stock pedal I would have to be pushing the pedal like 200lbs of force or more, and 7-14 times every lap and there is like 50+ laps a day. So hind site is 20/20. I have to change the pedal ratio. I have to change the pedal. I will use some sweet brake pressure calculators and figure out what it will take to keep the brake pedal feel I have now but with the larger MC and NO brake booster.

Also the car almost starts backwards when it is cold outside. So I am waiting for a nice COLD week and I will be dropping the car off at the dyno. The JnS works great the motor is all nicely broke in and the cams should be easily adjustable. Also the cold air helps with the numbers too. Ill post up the numbers in the race to 1-1 NA thread, but I'm sure as soon as I do that someone will come back and trump me.

The last tiny bit of plans for this year are to get a new seat that actually has support and is not to look cool (cost too much) get new belts since they expire this year and lastly get a new pc680 battery as this little dude is 8 years old!

<iframe width="420" height="315" src="//www.youtube.com/embed/cUdJmBH_krA?rel=0" frameborder="0" allowfullscreen></iframe>

So the whole reason I went this route is to get a consistent pedal. I thought it was due only because of the lack of vacuum with these huge cams installed. Well turns out that was only half the problem (or third if you wanted to install stiffer suspension components that would have to be one off or some sort of retro fit). Our MC is much larger at about 1". This MC pushes so much fluid that it masks the knockback that naturally occurs in street cars. However racing at the "line" any inconstancy will mean square tires or loosing a place in the race. However to move that much fluid you would need the booster, the thing I can't rely on any more.

So me being the cheap ass I tried the 2lbs and 10lbs line residual pressure valves. They don't work for s***. The second anything comes up over 10lbs it just blows by the valve. So I tried the anti knockback springs... Nope. To get this car to brake even more consistent I am thinking I will need to surpass the 1" and go to somewhere around the 1 1/8" area. However with the stock pedal I would have to be pushing the pedal like 200lbs of force or more, and 7-14 times every lap and there is like 50+ laps a day. So hind site is 20/20. I have to change the pedal ratio. I have to change the pedal. I will use some sweet brake pressure calculators and figure out what it will take to keep the brake pedal feel I have now but with the larger MC and NO brake booster.

Also the car almost starts backwards when it is cold outside. So I am waiting for a nice COLD week and I will be dropping the car off at the dyno. The JnS works great the motor is all nicely broke in and the cams should be easily adjustable. Also the cold air helps with the numbers too. Ill post up the numbers in the race to 1-1 NA thread, but I'm sure as soon as I do that someone will come back and trump me.

The last tiny bit of plans for this year are to get a new seat that actually has support and is not to look cool (cost too much) get new belts since they expire this year and lastly get a new pc680 battery as this little dude is 8 years old!

Last edited:

Got to the dyno and he said that the coolant temp was way off and that is why the motor wont start. Also we tried moving the cam gears around quite a bit and never could get ride of that top end overlap. Also output #1 made the relay click but did not activate the viss. I will try and get that going here too. Got the new seat ordered bk pedal and mc are here. However I got the gm temp sensor and slapped that guy in there so I would not share the stock one just to have the starter finally die. The microtech readings where only 10* off instead of the 20-30* off that they where before.

Its getting cold here and I just want to stop with this and let my credit card cool off. SOooo annoying.

Its getting cold here and I just want to stop with this and let my credit card cool off. SOooo annoying.

Last edited:

Where are you located at? I see that you race at Gingerman which isn't to far away from me. I like following the thread because it shows the complete difference between your setup for track and mine for autoX with limited track time.

New Posts and Comments

- Replies

- 15

- Views

- 8K

- Replies

- 1

- Views

- 100

- Replies

- 9K

- Views

- 3M

- Replies

- 121

- Views

- 44K