A plan?

So first of all what is the plan?

Terry already equipped the car with a Microtech Standalone EMS which works wonderfully as well as a spool mani, Evo III 16G, FMIC, a secondary fuel rail and 8 550cc injectors, plus the necessary support for that. I've since added a JandS safeguard, PLX Wideband, changed to a Walbro 255 in tank pump, and put in a welded MSP LSD. (there is more detail in my sig). The car was wonderfully fun to drive, but seemed to be on its way out in the month before it blew up. It didn't matter how I tuned it, or if I bumped up the boost another 4 psi... the car just wouldn't get any faster. Then during my race it started running far richer than it was programmed to and a couple minutes later the number 4 rod gave out and blew a massive hole in my block and upper oil pan. Metal and oil everywhere!!!!

So that gets us to here... and here is the list of "to come" items.

Cold Air Intake

Rebalanced Injectors

AEM adjustable FPR

Ported and Polished Intake Manifold

Removed VTCS, VICS and EGR

Ported and Polished Head

Ported and Polished exhaust manifold

Ported and polished hot and cold side Evo III 16G turbo

3 angle valve job with back-cutting (standard valve size)

Ferrea Exhaust Valves

Chamfered Oil Galley Ports

CP 8.9:1 pistons

CP Nitrided Rings

Oliver Forged Rods

Spec Stage 3+ full face clutch

Mitsubishi Eclipse Evo III O2 housing matched and polished

Balanced Crank

Toga Rod and Main Bearings (FlatLanderRacing MBMA17-HP and RBMA17-HP for a total of 138.49 for the rods and mains)

EDIT: Edited to actual final list.

I also got a lightly used (4,000 miles) Mazdaspeed motor that I have already torn completely down and will be building up with all this as my replacement motor. It is currently in for an align honing on the mains, a glaze break on the cylinder walls, and a check of the deck as well as a good hot tanking. Then it will be coated in WD40 basically cleaned and packaged to be stored for the next month or so until I can start adding more parts as I have the money.

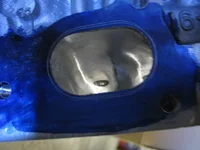

One of the things I learned right away is that there are a lot of "little" machining things that you can "skip" but aren't good ideas to skip over. One example is my cylinder walls. They are in PERFECT shape... (see pictures) and are so new that the hatching is still visible. However, for the new rings to seat in properly they need to have the right surface roughness to wear the rings as is needed. This roughness level varies based on the rings you use and so does the angle of the cross hatch! Spending the whopping 4-8 dollars per cylinder for the honing is such a simple and cheap thing there is NO reason not to do it!

Also, to ensure that your crank is loaded as evenly as possible it is best to have your block's mains align honed. By doing so you ensure that they are nearly perfectly aligned to one another and that the crank and all forces will be distributed as evenly as possible. Along these lines, having your crank balanced will help it be even smoother in it's rotation than it is in stock form (smooth in a vibrational sense). Our pistons, rods, and crank are balanced from the factory, but not to very tight tolerances, and you can gain some improvement by having them re-balanced by a machine shop. Balancing is also relatively cheap. A crank balance is 50-75 dollars, and piston balancing is roughly 40 dollars.

Additionally, if you have the block in... get it cleaned up! Getting it hot tanked is generally a must anyway for machining to make sure that all the oils are off of it and that there isn't any extra dust and rust hanging around.

It is of note as I found out today that our oil squirters are press fit into the block. They can be removed, but then new ones should be pressed back into the block when machining and so forth is complete!

Some pictures and links will be added to this post soon hopefully!

Next Up: Cleaning and rewiring my engine bay as well as painting the block!

Pics: new_motor_4: The crosshatch of the new motor still visible even with 4k on it!

oil_squirter: a pic from the bottom of the engine of an oil squirter

water_pump_and_seat: The water pump removed... simple device!

uncapped_crank: all caps and bearings removed from the crank.

Zip of about 50 of my new motor teardown pics: about 3.1mb

http://www.nsnmotorsports.com/MP3Build/NewMotor1.zip

Includes water pump, oil pump, main caps, cylinders, head, etc...