Update on progress!

**********************************************************

Update: 9/23/2009

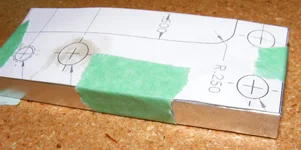

I finished the prints for the short-throw shifter plate today. Because I'm a good engineer I made a prototype out of some aluminum to check the fit-up, and it looks bang-on (machining the aluminum takes about 1/4 the time as the Ti). Clearances all look good too! Unfortunately I need longer bolts to mount it and test everything while driving, and the hardware store was closed when I finished machining it. However, with this good indication I'm going to start machining the Titanium part either tomorrow or Friday, depending on how much free time I have. Tomorrow I should be able to post the drawing I used in *.pdf format.

There are two different ways to go about making your own shifter plate:

Pro way- Look at the drawing and machine everything as it is indicated. Not a very practical option if you don't have a mill, unfortunately.

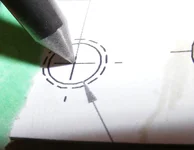

Everyone else way- Cut out the outline of drawing either by measuring and marking, or by taping the print right to the metal stock and using a punch and hammer(a nail works if you don't have a punch) to transfer all of the corners and hole centers, marking between the corners to get an outline to cut/sand/grind, and pilot-drilling at the hole center punches.

I did my aluminum piece half-and-half. I machined the outside profile out of an aluminum plate (3/8" was what I had to work with) and then taped a cut-out of the print to it and punched the hole locations through. I ran a small pilot drill through each hole location, drilled the full diameter hole, then tapped the ball-joint mounting hole (remember lots of oil when you tap, and turn back every now and then to break the chip).

I sourced the ball-stud from McMaster-Carr (which is freakin awesome if you haven't purchased from them before). You could get different sizes and even SS ball-studs if that's what gets you going.

McMaster PN: 9512K73

And I also found a steel plate with the ball-stud already mounted in it. So if you need the material, don't have a tap, or want to get it done the fastest way, get it!

McMaster PN: 9512K61

Again, stay tuned for updates! Ti plate to come shortly, and I'll probably be looking to sell the aluminum one I made at some point.

******************************************

Update 1

*.pdf of drawing has been uploaded! I know there's no tolerances on it, and that's because I imagine it's going to be made in many different ways to many different tolerances depending on what's available to a particular person, just use your common sense, and over-drill holes if needed.

It is for anyone to use, free of charge, and let's keep it that way. I just want credit for my work, not money. If you find someone using it for profit let me know and I'll (dark) Other than that, enjoy! Post pictures of your end product if you use it!

******************************************

Update 2

Using SolidWorks I have figured out that I need to slightly reduce the weight of my shifter weight in order to maintain the system's inertia when I add the STS plate. This is important to maintain the same shifting "feel".

******************************************

Update 3

I have corrected the drawing so that the plate clears other shifter components.