Word...I'm waiting for Pat to get back in town so I can get my spare head out of his garage.01bluemp3 said:Ill help pitch in i wanna get my car on there too, and that will let me know if i wanna port and polish.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XelderX's Intake Porting

- Thread starter xelderx

- Start date

twilightprotege

Member

- :

- 2001 323 Astina SP20 (P5)

sorry, i did headwork and cams at the same time

OK guys. Sorry for the lack of updating. I got a little impatient and rushed to get the head back on the car. I'll be posting picks of the the head and install later. I've been driving the car around for a few days and this is what I've come up with.

First. My car should be much slower now than when I started this since while I was finishing the port job I replaced my 15 inch rims/Azenis w/ the stock rims with super heavy/tall 205/55 all season tires. The gearing is much taller now and should slow down acceleration.

Second. Above 4,000 RPM this thing is much faster. I mean...puts a grin on your face...best thing I've done to the car since switching to 15 inch rims. I didn't lose anything below 4,000 so there is no sacrifice in the low end with what I've done. My car rarely gets driven below 3500 anyway. I can't wait to put the 15 inch rims back on.

Third. The only problem I can find in this setup is that there is a slight hesitation around 5,000 RPM if I'm only at partial throttle. Put your foot on the floor and it never stops pulling all the way to the rev limiter, but if you are just accelerating at half throttle it gets a momentary stumble in it until you go ahead and give WOT.

I'm hoping a little tuning w/ a Haltech E6X will solve the hesitation (jeez I need money) and I'm still not done with my exhaust. I'm running a Wagner shorty header right now with a gutted pre-cat, but thats all coming off for a Racing Mazda header very soon. We'll have to wait and see what happens when the exhaust is done.

First. My car should be much slower now than when I started this since while I was finishing the port job I replaced my 15 inch rims/Azenis w/ the stock rims with super heavy/tall 205/55 all season tires. The gearing is much taller now and should slow down acceleration.

Second. Above 4,000 RPM this thing is much faster. I mean...puts a grin on your face...best thing I've done to the car since switching to 15 inch rims. I didn't lose anything below 4,000 so there is no sacrifice in the low end with what I've done. My car rarely gets driven below 3500 anyway. I can't wait to put the 15 inch rims back on.

Third. The only problem I can find in this setup is that there is a slight hesitation around 5,000 RPM if I'm only at partial throttle. Put your foot on the floor and it never stops pulling all the way to the rev limiter, but if you are just accelerating at half throttle it gets a momentary stumble in it until you go ahead and give WOT.

I'm hoping a little tuning w/ a Haltech E6X will solve the hesitation (jeez I need money) and I'm still not done with my exhaust. I'm running a Wagner shorty header right now with a gutted pre-cat, but thats all coming off for a Racing Mazda header very soon. We'll have to wait and see what happens when the exhaust is done.

twilightprotege

Member

- :

- 2001 323 Astina SP20 (P5)

nice!

Super Matty P

Banned

- :

- 2003 Supercharged Protege5

you're doing all this porting by hand with a file and rasp?? sheesh man. I wish you woulda let me know you were going to do this I could've helped you out a bit.

in all honesty though I have a pretty strong opinion of these "hand jobs" (as I refer to them). Just making the ports larger or removing some casting flash is not always the best thing to do. There is a science behind this and you can't create the same flow path with your hands (or dremel) as you can with science. I preach about the benefits of Extrude Hone porting and I think a lot of people don't understand why. So here's my thoughts on it:

Extrude Hone's AFM process uses a liquid abbrassive putty to hollow out the air path. The reason this is important is that liquid travels just like air would. EH uses high-pressure to fill the runner with this putty. By forcing the putty back and forth you remove only the metal that is an obstruction.

Removing too much metal or not getting it even in all chambers causes air turbulence and other driveability problems. I'm not saying a good "hand job" wont help but it's much easier to cause problems than power.

EH offers stage 2 gasket matching for about $80 per peice....worth every penny (IMO). You provide the IM gasket and they will port it out to that gasket limit while polishing it at the same time. As I've stated before a head and IM with stage 2 on both is about $950+shipping....VERY good price for what you get. I plan on doing this real soon if I decide to keep the car.

in all honesty though I have a pretty strong opinion of these "hand jobs" (as I refer to them). Just making the ports larger or removing some casting flash is not always the best thing to do. There is a science behind this and you can't create the same flow path with your hands (or dremel) as you can with science. I preach about the benefits of Extrude Hone porting and I think a lot of people don't understand why. So here's my thoughts on it:

Extrude Hone's AFM process uses a liquid abbrassive putty to hollow out the air path. The reason this is important is that liquid travels just like air would. EH uses high-pressure to fill the runner with this putty. By forcing the putty back and forth you remove only the metal that is an obstruction.

Removing too much metal or not getting it even in all chambers causes air turbulence and other driveability problems. I'm not saying a good "hand job" wont help but it's much easier to cause problems than power.

EH offers stage 2 gasket matching for about $80 per peice....worth every penny (IMO). You provide the IM gasket and they will port it out to that gasket limit while polishing it at the same time. As I've stated before a head and IM with stage 2 on both is about $950+shipping....VERY good price for what you get. I plan on doing this real soon if I decide to keep the car.

Super Matty P

Banned

- :

- 2003 Supercharged Protege5

it's controlled at the valve seat and intake port. IT is a 2-way process that pushes the putty back and forth from one point to the other but the putty never goes through the port on the valve seat.

- :

- 2002 BJFW, 2007 BK3P, 1979 SA22C, 2005 BK3P

why a racing mazda header over the ractive, obx or awr?

Super Matty P said:you're doing all this porting by hand with a file and rasp?? sheesh man. I wish you woulda let me know you were going to do this I could've helped you out a bit.

in all honesty though I have a pretty strong opinion of these "hand jobs" (as I refer to them). Just making the ports larger or removing some casting flash is not always the best thing to do. There is a science behind this and you can't create the same flow path with your hands (or dremel) as you can with science. I preach about the benefits of Extrude Hone porting and I think a lot of people don't understand why. So here's my thoughts on it:

Extrude Hone's AFM process uses a liquid abbrassive putty to hollow out the air path. The reason this is important is that liquid travels just like air would. EH uses high-pressure to fill the runner with this putty. By forcing the putty back and forth you remove only the metal that is an obstruction.

Removing too much metal or not getting it even in all chambers causes air turbulence and other driveability problems. I'm not saying a good "hand job" wont help but it's much easier to cause problems than power.

EH offers stage 2 gasket matching for about $80 per peice....worth every penny (IMO). You provide the IM gasket and they will port it out to that gasket limit while polishing it at the same time. As I've stated before a head and IM with stage 2 on both is about $950+shipping....VERY good price for what you get. I plan on doing this real soon if I decide to keep the car.

This is very good advice and I know tha I was taking a chance with doing it by hand. I still have another intake manifold sitting around that may someday get the EH process applied to it. when I started this project though I just couldn't sacrifice the extra money and I was really interested in doing it myself. I was optimistic about how it would turn out, but I was fully aware that I could have done more damage than good. Having another head and intake manifold made it easy to just swap out if I had made a mistake though. I'm more than happy with the results and I learned a lot while I was working on it.

ps...I didn't do the whole thing by hand with a file. That was just the first night I was playing around with it. I found a spherical die grinder bit that worked perfectly the next day. The polishing took the longest time.

Captain KRM P5 said:why a racing mazda header over the ractive, obx or awr?

I've considered all the header options. The 4-1 from OBX would be the easiest and cheapest option, but I'm not sure I would be satisfied with the way it moves the torque curve. i'm pretty dead set on a 4-2-1. I'm too familiar with how much difference a 4-2-1 compared to a 4-1 makes on motorcycles. The 4-2-1 should be more to my liking even if the differences are only minimal. I have to ring every bit of drivability and full range power out of this car to compete with the much lighter VW's in my class. i haven't completely decided between the AWR an RM header just yet since I haven't talked to AWR or RM personally about my concerns. Tony at AWR has always been great with me, but I'm will ing to give both companies a shot at getting my business and the RM header has just caught my eye and curiousity more than the AWR. I know there have been a few problems with both headers, but I'm willing to take that chance.

Super Matty P

Banned

- :

- 2003 Supercharged Protege5

you can't compare how a header affects a motorcycle to how it'll affect a passenger car.

I read a very large write-up by a respected import magazine where they took a 1.8L honda engine and tried out 6 different headers including the stock piece and found the difference between a 4-1 and a 4-2-1 was less than 2whp in the midrange. I couldn't justfiy the price for 2whp but if you can.....

If you're happy with your head and IM that you have now let me know if you want to unload that spare.

I read a very large write-up by a respected import magazine where they took a 1.8L honda engine and tried out 6 different headers including the stock piece and found the difference between a 4-1 and a 4-2-1 was less than 2whp in the midrange. I couldn't justfiy the price for 2whp but if you can.....

If you're happy with your head and IM that you have now let me know if you want to unload that spare.

- :

- 2002 BJFW, 2007 BK3P, 1979 SA22C, 2005 BK3P

xelderx said:I've considered all the header options. The 4-1 from OBX would be the easiest and cheapest option, but I'm not sure I would be satisfied with the way it moves the torque curve. i'm pretty dead set on a 4-2-1. I'm too familiar with how much difference a 4-2-1 compared to a 4-1 makes on motorcycles. The 4-2-1 should be more to my liking even if the differences are only minimal. I have to ring every bit of drivability and full range power out of this car to compete with the much lighter VW's in my class. i haven't completely decided between the AWR an RM header just yet since I haven't talked to AWR or RM personally about my concerns. Tony at AWR has always been great with me, but I'm will ing to give both companies a shot at getting my business and the RM header has just caught my eye and curiousity more than the AWR. I know there have been a few problems with both headers, but I'm willing to take that chance.

cool, just curious especially since i have heard questionable things about RM quality

Super Matty P said:I read a very large write-up by a respected import magazine where they took a 1.8L honda engine and tried out 6 different headers including the stock piece and found the difference between a 4-1 and a 4-2-1 was less than 2whp in the midrange. I couldn't justfiy the price for 2whp but if you can.....

If you're happy with your head and IM that you have now let me know if you want to unload that spare.

One of our races last year the FTD was decided by 6/100th's of a second. At the end of the year that could be the difference between a club championship and second place. To 99% of the people 2 whp wouldn't be worth it, but in the long run I'm even considering much more costly mods for even more minimal gains. When you lose by 6/100th's of a second and you couldn't have drove any better..every hp you can gain and pound of weight you can lose makes or breakes you. On motorcycles the effects are greatly exagerated due to their extreme power to weight ratios, but the concepts are still very similiar. 4 pistons, small displacement, high reving (relatively speaking), very similiar engine size to exhaust length scale. They are not mirror images, and I see your point totally, but we can also sit here and argue Mazda head design vs. the Hondas that were tested. Blah...I guess you could say that if I was in it for every HP I would have taken a little more time and money to do this port job and you would be totally correct.

I'm still stuck in the grassroots racing ideal and I like to do everything I can by myself. It makes the improvements all that much more enjoyable. So how about the N/A tuning info on that Haltech?

You're in no-man's land on this one. Matty is right. You just can't go in there and start hogging stuff out. You should have put your head/manifold on the flow bench first, and let it tell you how much air you're capable of flowing. If they can support more power at an RPM you'll never see, then you've wasted your time. Port and runner shape is more imporant than size. Yes, more flow is good, but never at the expense of velocity. A good understanding of laminar flow helps. There's no doubt you've helped out your high RPM flow, but as you've already stated, you've killed your throttle response. Done right, you CAN have the best of both worlds. I've done some port/manifold work myself on my spare engine, but mostly just cleaning up the castings and some port matching.

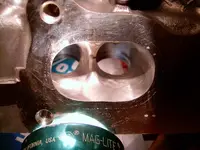

I have the luxury of having my spare head and header flange, so I port matched them while removing as little material as possible. I also cleaned up the castings on the intake manifold and exhaust ports. I left the intake ports alone, as the rough texture maintains fuel atomization.

I have the luxury of having my spare head and header flange, so I port matched them while removing as little material as possible. I also cleaned up the castings on the intake manifold and exhaust ports. I left the intake ports alone, as the rough texture maintains fuel atomization.

Attachments

twilightprotege

Member

- :

- 2001 323 Astina SP20 (P5)

gee stock cast stuff is crap!!!

josh i'm suprised you didnt make the bridge there more knife like...

josh i'm suprised you didnt make the bridge there more knife like...

Gen1GT said:You're in no-man's land on this one. Matty is right. You just can't go in there and start hogging stuff out. You should have put your head/manifold on the flow bench first, and let it tell you how much air you're capable of flowing. If they can support more power at an RPM you'll never see, then you've wasted your time. Port and runner shape is more imporant than size. Yes, more flow is good, but never at the expense of velocity. A good understanding of laminar flow helps. There's no doubt you've helped out your high RPM flow, but as you've already stated, you've killed your throttle response. Done right, you CAN have the best of both worlds. I've done some port/manifold work myself on my spare engine, but mostly just cleaning up the castings and some port matching.

I have the luxury of having my spare head and header flange, so I port matched them while removing as little material as possible. I also cleaned up the castings on the intake manifold and exhaust ports. I left the intake ports alone, as the rough texture maintains fuel atomization.

Very true. But I didn't lose throttle response. All that is just as good if not better. The hesitation comes from just lazily accelerating with the throttle half depressed...which basically only happens when I'm driving around town. When I'm out racing the throttle is usually either pinned or nothing so the hesitation never comes into play. I think we can agree that I could stand to gain much more if this was professionally done, but I did it for free and still gained tremendously more than I expected. It is still a win win situation for me. I still have that stock manifold and head hanging around that may get a more professional job when the time and money allows, but for now I couldn't be happier and the money is being spent on much more lucrative go fast items like new suspension, LSD, and wheels/tires.

- :

- Hemi Ram, 71 Plymth Scamp, 71 Plymth Duster 340, 69 Dart 340/4sp

BlkZoomZoom said:here's a couple of pics of my current head project. I hope to be finished by the end of next week and have post port flow numbers later.

I saw those on the other threads and I really wish I could go that far, but the SCCA loves to write rules. So I'm only allowed 1 inch from the gasket surface to play with.

Xelderx, what you described, is a loss in throttle response. When you're at part throttle and mash it, the time it takes for the engine to build power is throttle response. What I believe has happened is that you've lost velocity. You may not realize is, but for any given speed, you're probably deeper into the throttle at any given time.

As long as you're enjoying driving your car now more, is all that matters though......

As long as you're enjoying driving your car now more, is all that matters though......

New Posts and Comments

- Replies

- 28

- Views

- 11K

- Replies

- 0

- Views

- 57