You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ventpod Group Buy Feeler!

- Thread starter LtTroyer

- Start date

- Status

- Not open for further replies.

Elbows-High

Member

I thought so. Do you know whether or not the CX-7 is the same as the 6? I'm working on an adapter solution for the 6 so that this pod will fit that model as well.

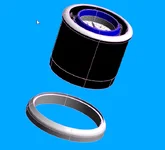

In the mean time, here are some more pics of my CAD. I've modeled a rudimentary gauge so you get a better feel for it. (see first post)

In the mean time, here are some more pics of my CAD. I've modeled a rudimentary gauge so you get a better feel for it. (see first post)

Last edited:

Elbows-High

Member

Thanks!

07SilverSpeed6

Member

- :

- '08 Mazdaspeed3

I will try to remember to measure the vent on my 6 tonight.

TurboDreams

Member

- :

- 2008.5 MS3 Metropolitan Gray

count me in for one

Elbows-High

Member

Prototype is on it's way to me now.

Elbows-High

Member

Prototype is HERE!! I'm in the middle of painting it, but I'll but some pics of it "in the raw" before I'm done with it.

It's a bit grainy, as I may have mentioned, due to the process used to "grow" it, but I should be able to sand that out. The production units will NOT be grainy. They will have a nice glossy finish.

Anyhow, stay tuned for pics.

EDIT: PICS! Next Stage is to test fit in my colleague's car on Monday. It's designed to slip fit into the OE vent pocket. With the right diameter, this should be a perfect fit.

It's a bit grainy, as I may have mentioned, due to the process used to "grow" it, but I should be able to sand that out. The production units will NOT be grainy. They will have a nice glossy finish.

Anyhow, stay tuned for pics.

EDIT: PICS! Next Stage is to test fit in my colleague's car on Monday. It's designed to slip fit into the OE vent pocket. With the right diameter, this should be a perfect fit.

Attachments

Last edited:

Elbows-High

Member

I've been working on something for the Mazda 6 also. This would be an additional piece that would enable a nice, tight slip fit into the 6's dash opening.

Anyhow, have a look, lemme know your thoughts. I think I'll need to actually make one and get pics to give a better feel. I'm working on that.

Anyhow, have a look, lemme know your thoughts. I think I'll need to actually make one and get pics to give a better feel. I'm working on that.

Attachments

Last edited:

blake_peanut

Member

- :

- 2008 CWP MS3

SUB - Count me in for one of these!

- :

- 2011 Mustang GT

I'm interested as well...any plans for a 60mm gauge pod just like this? I know some people want to run the Defi Racer BF's with the Defi-link system, and those are only 60mm gauges.

Awesome too how you actually took the time to model in CAD and generate it. Props for that!

Awesome too how you actually took the time to model in CAD and generate it. Props for that!

Elbows-High

Member

Yeah, the CAD allows me to output an IGES file, which my prototype source plugs into his ABS printing machine. The only reason I need a drawing is to communicate where and how tight the tolerances will be.

Several have asked about a 60 mm gauge option. My initial thought is that it will definitely cut off air flow. The ID of the barrel is only 71. I have to add 3 mm of material to the radius of the gauge to form the inner barrel. This puts the OD of that barrel at 66. That only leaves 2.5 mm radially for the air to flow through, and in fact less because you have to factor in draft.

That being said, I'm going to model something up and post it for you to look at. I may be able to get around that 3 mm of material requirement.

While I'd love to be able to offer both sizes, the reality of needing two tools to do it will more than likely keep me from doing so. But like I said, lemme think on it a bit. I'll post back.

EDIT: Here's a thought....we could simply remove material from the 52 mm pod after it is molded. This might be something I could do before shipping it. I'd have to make some sort of template. Or, this could be done buy the end user.

The six "legs" should be enough to hold a gauge in place. If we are able to get enough people in a GP, I'll see it I can cannibalize one for this project.

Several have asked about a 60 mm gauge option. My initial thought is that it will definitely cut off air flow. The ID of the barrel is only 71. I have to add 3 mm of material to the radius of the gauge to form the inner barrel. This puts the OD of that barrel at 66. That only leaves 2.5 mm radially for the air to flow through, and in fact less because you have to factor in draft.

That being said, I'm going to model something up and post it for you to look at. I may be able to get around that 3 mm of material requirement.

While I'd love to be able to offer both sizes, the reality of needing two tools to do it will more than likely keep me from doing so. But like I said, lemme think on it a bit. I'll post back.

EDIT: Here's a thought....we could simply remove material from the 52 mm pod after it is molded. This might be something I could do before shipping it. I'd have to make some sort of template. Or, this could be done buy the end user.

The six "legs" should be enough to hold a gauge in place. If we are able to get enough people in a GP, I'll see it I can cannibalize one for this project.

Attachments

Last edited:

Antoniogut

Member

id buy! (the 52mm) you can add me to the list

Bonafide_Spd3

Member

- :

- 2007 Mazdaspeed3 GT Cosmic Blue

I'll take one as well if the price is right, It looks great

Elbows-High

Member

Wait 'til you guys see the pics in vehicle!! It looks like it belongs there from the factory! I just slipped the prototype into a colleagues MS3. It looks great. Stay tuned for pics. I might not be able to get them up until later tonite, so hang in there.

- Status

- Not open for further replies.

New Posts and Comments

- Replies

- 4

- Views

- 111