you need mods and low temps for the fuel pump on the ms3 to begin to pop. I can't stress this enough.

Right but Dada's saying your data suggest you had a bad stock pump? im trying to see his perspective.

you need mods and low temps for the fuel pump on the ms3 to begin to pop. I can't stress this enough.

Right but Dada's saying your data suggest you had a bad stock pump? im trying to see his perspective.

maybe he did

so did i!!

you need mods and low temps for the fuel pump on the ms3 to begin to pop. I can't stress this enough.

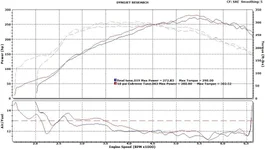

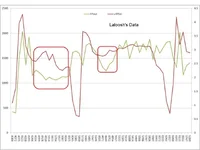

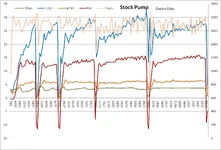

The first and second graphs both show high TPS voltages with increasing rpm and lower than normal fuel pressures. The specific regions are boxed in red. The third one is just the rest of the datalog in the interest of showing all of the data. Compare that to Nypest's data at the top of this page. http://www.mazdas247.com/forum/attachment.php?attachmentid=122448

dadasracecar is using a different fuel pump. his is a prototype CP-e pump. if i read right, his pump on the standback showed a maximum of 1900psi where ours - as reported by laloosh on his standback- shows 2200psi maximum. his dyno numbers should not be considered wholly representative of how our pump will affect a vehicle. laloosh, mrlilguy, driver311, palerider have all reported much better driving characteristics with our pump. this has not yet been reflected in any kind of dyno results, but we're all working towards that to show what kind of difference its going to make on the dyno. holidays being what they are have been slowing us all down. i'll have more for everyone in the next few days.

you know what would be really funny if it turns out that its the intank pump thats the culprit, hahaha would be funny if it just wasnt able to supply enough fuel to keep up with the oem cam drivin pump up front, making it loose pressure. has anyone considered this???? just a thought...IDK

then upgrading the cam driven pump would do nothing at all because the cam driven pump does not forcibly draw fuel through the line from the tank pump. if that were the case there would be no reason to have a redundant tank pump whatsoever.