Hi,

Due to ball joints clunks I’m replacing the lower control arms.

While the passenger side went smooth the driver side is a major issue.

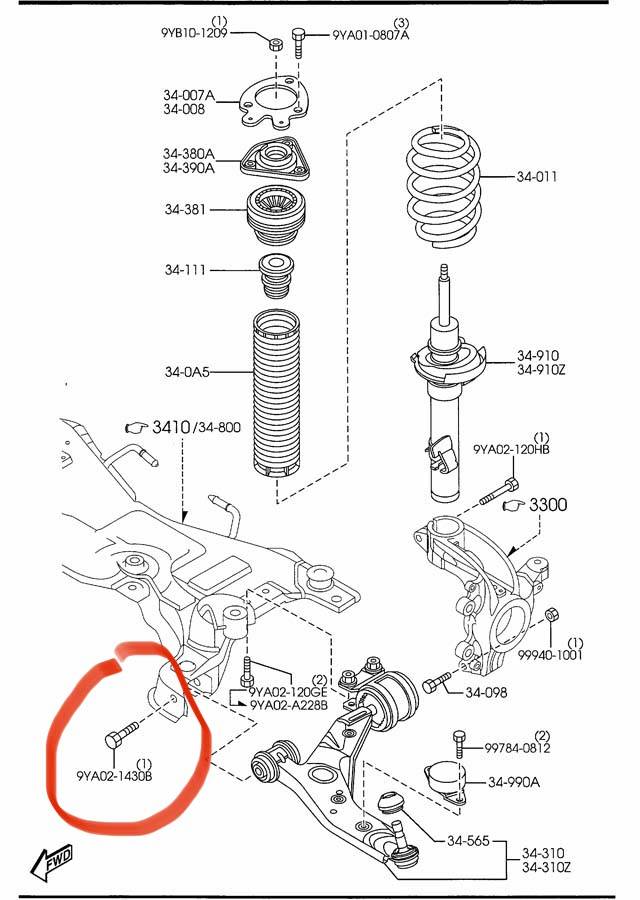

I can not remove the front bolt of the lower control arm as it appears to be “stuck”, welded like no matter what I do.

See photo for the bolt.

heated hammered on blasted and using power tools and hands.

The issue is that the welded nut is inside the subframe and can only access to tiny crack on the subframe to spray some on blaster.

After 3 hours on this bolt I gave up and I’m at a stand still.

I appreciate any input.

thank you

Due to ball joints clunks I’m replacing the lower control arms.

While the passenger side went smooth the driver side is a major issue.

I can not remove the front bolt of the lower control arm as it appears to be “stuck”, welded like no matter what I do.

See photo for the bolt.

heated hammered on blasted and using power tools and hands.

The issue is that the welded nut is inside the subframe and can only access to tiny crack on the subframe to spray some on blaster.

After 3 hours on this bolt I gave up and I’m at a stand still.

I appreciate any input.

thank you