Installation of the B&M Pro Ratchet happenned during the week. A huge thanks to rodneooo for his help in answering questions.

Here the heavy lifting begins...

I started by removing all of the center console and CCS / stereo system so that I could begin 'modifying' the transmission tunnel on the Cosmo so the ratchet cable can go through the floor. I used a 13mm drill bit to start the process and then a die grinder with a carbide-tungsten bur to increase the diameter of the hole.

Here is a better of look at where to drill...

You will need to drill through the plastic, through the floor of the car & then through two separate heat shield layers to get to the outside of the car. You will also need to drill at an angle - approx 30 degrees as the shifter cable needs to be as straight as possible as it leaves the shifter. This is where having a die grinder is a must. I should also add that you should not bolt the shifter in just yet as it makes it impossible to slide the cable through.

You will also need to trim the carpet back in this section of the car. Do not try and drill through it!

Above is the hole before I painted & siliconed it. I used some extension bars to massage the holes so that they had the best alignment.

The next step is to jack the car up, go underneath and remove the exhaust. I actually had a separate set of flanges installed so that I only needed to remove a very small section of the exhaust. Once the exhaust is off, you will need to remove the heat shield protecting the driver side of the gearbox. You will also need to remove the mounting points from the sump. Be careful when you do this and only remove one bolt at a time. Once you have removed each bracket, replace the corresponding sump bolt to avoid making a huge mess.

You now need to run the cable to through the floor pan. The easiest way to do this is to remove the 11/16 nuts from the end of the cable. Feed it down the passenger side of the box. Put your hand down the hole where the shifter used to be to help guide it. You basically want it to go straight down towards the ground.

Once it is through, it is time to bolt the other end to the shifter and then bolt the shifter to the trans tunnel. If you don't do this now, you will not be able to correctly align the shifter cable as it will want to rotate too much.

Get under the car & remove the upper heat shield which resides above the cats. Do not remove the whole thing, just the first two pairs of 10mm bolts which hold it in place. If you remove the whole thing then it becomes an uber pain the ass to put back if you are doing this by yourself.

The shifter cable needs to go back towards the rear of the car above the heat shield and then loop fowards on the drivers side so it is pointing fowards on the drivers side of the box. The normal 5ft cable which comes with the B&M kit is perfect - no need to order something else.

This is pretty much the point of no-return. Remove the old, solid shifter linkage from under the car by removing the circlip. Leave the shifter cable dangling here for now.

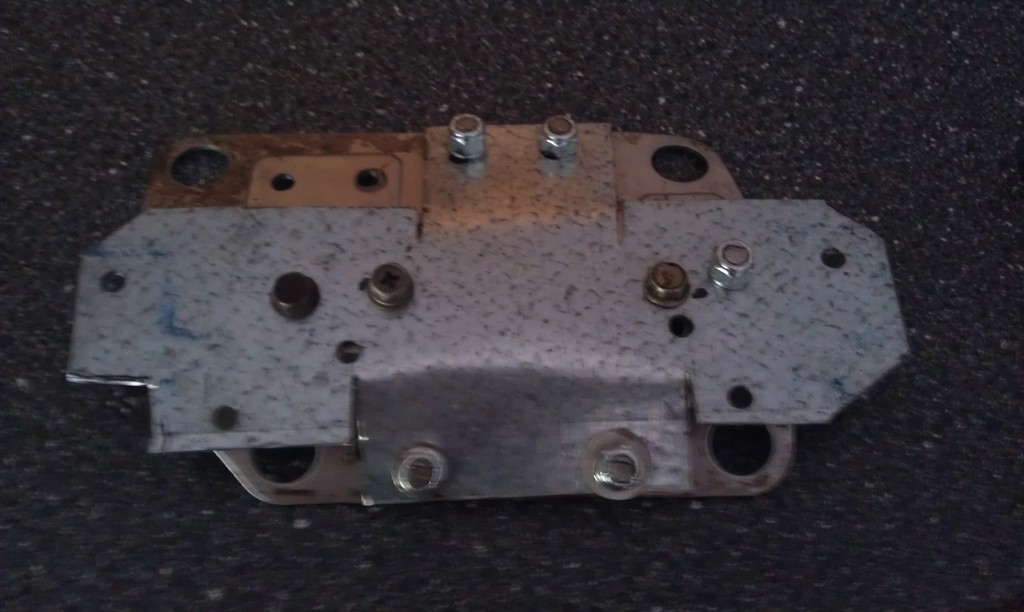

There is a support bracket which holds the exhaust is place which needs to go on a diet in order to fit the new shifter linkage. Although this is a terrible picture, you can see where I have taken a large notch out of it...

Once you have trimmed this piece, put it back on the car. Now you need to install the shifter brackets and linkage. Note that you will need to purchase some 25mm M6 bolts to do the job as well as some small washers to act as spacers. You could also try to die-grind the lip of the sump to allow the bracket to fit better, however I do not recommend this as the lip is designed to strengthen the sump pan.

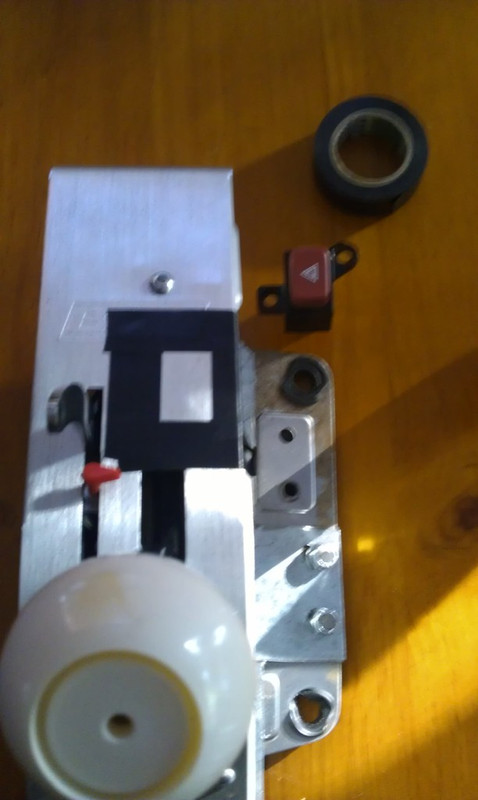

Here you can see the bracket and linkage installed.

The cool thing about the standard box is that you don't need to cut off or remove the linkage on the box. The new linkage simply attaches over the top of the old one. Before hooking the cable up, ensure that the ratchet has had the 'park limiter' pin installed and is in the same gear position that you left the car in before removing the factory shifter.

Now the fun part comes.. adjusting the cable to ensure it goes into gear. I am not going to go into this here as there is a lot written about this already. My #1 piece of advice though is that this is a two person job. Get a mate to sit in the car and go through the gears while you (or your man servant) is under the car. Remove the linkage after every shift to ensure it is in gear. You will be able to feel this easily. In fact, the linkage will only come off if you have it properly in each gear. Adjust the cable using the 11/16th bolts as needed.

Once you are happy re-install the exhaust. Note that I could not find a good way to re-install the factory heat shield so I temporarily used heat-wrap on the exhaust until I could build something out of metal.

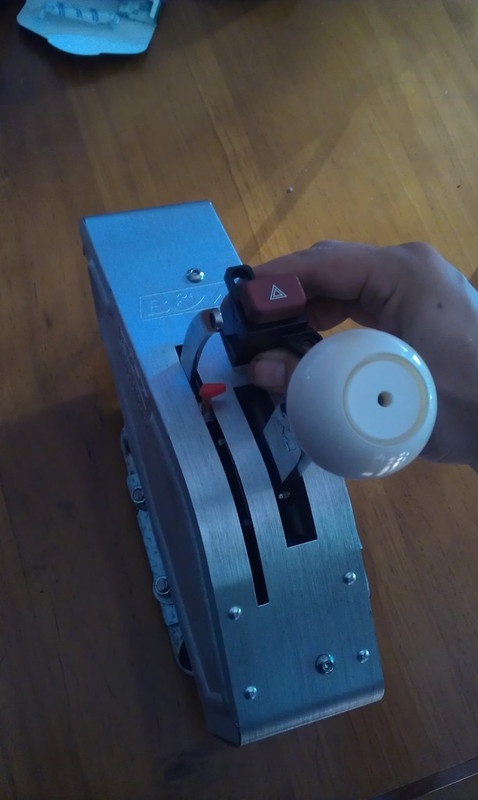

Here you can see it in the car... (excuse the mess!)

To get it to fit like this you will need to trim the metal housing of the shifter. Use an angle grinder to cut the front and rear off the housing - yes completely cut it off. You will then need to use a die-grinder to cut away about 4mm of plastic off the front of the electric seat button assembly. Even trimming the metal casing down, you will still need to do this. You could move the shifter forward slightly also. I didn't realize though until it was already too late.

More updates to come.