So it's been 3 weeks....

...and I've been a real slack ass keeping this thread up to date. Between work and the necessities of life, I've actually accomplished quite a bit. Meh, so I thought I would have it running a few weeks ago. Hell, I thought I'd have her running this weekend. Well, I've come to the determination that I can't even come close to guessing the amount of time required to design/build/assemble one thing or the other. I really do suck at that.

But anyway, the bits and peices, odds and ends, and crap that I found in the isles of the junk yard some where are starting to come together. Since it's been so long since the last update, I'll just give a brief rundown of the major areas of completion. Remember, however, that a large amount of time is, unfortunately, required in cleaning, sanding, grinding, painting, and overall unseen cosmetic crap.

The ever so brief rundown:

-the intercooler and radiator are permanantly mounted

-the intake manifold is connected to the intercooler

-the new coolant overflow reservoir is installed

-the turbo is upgraded and installed (larger compressor wheel/housing)

-the pre-I/C charge pipe is mostly complete

-the turbo outlet flange is CAD'ed and off to the machine shop (a new downpipe will be constructed)

-the front suspension is reassembled (yay, i have a front sway bar again)

-reassembly of the forward body panels has begun

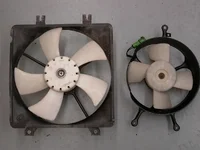

The next step is to complete the intake charge piping, install the radaitor fans and associated bracketry, and plumb the cooling system. I already have the majority of the materials required, so that shouldn't take too long. After that, it's just a matter of changing the oil, installing the plugs, and installing the down pipe.

I leave you with a few pictures....

...and I've been a real slack ass keeping this thread up to date. Between work and the necessities of life, I've actually accomplished quite a bit. Meh, so I thought I would have it running a few weeks ago. Hell, I thought I'd have her running this weekend. Well, I've come to the determination that I can't even come close to guessing the amount of time required to design/build/assemble one thing or the other. I really do suck at that.

But anyway, the bits and peices, odds and ends, and crap that I found in the isles of the junk yard some where are starting to come together. Since it's been so long since the last update, I'll just give a brief rundown of the major areas of completion. Remember, however, that a large amount of time is, unfortunately, required in cleaning, sanding, grinding, painting, and overall unseen cosmetic crap.

The ever so brief rundown:

-the intercooler and radiator are permanantly mounted

-the intake manifold is connected to the intercooler

-the new coolant overflow reservoir is installed

-the turbo is upgraded and installed (larger compressor wheel/housing)

-the pre-I/C charge pipe is mostly complete

-the turbo outlet flange is CAD'ed and off to the machine shop (a new downpipe will be constructed)

-the front suspension is reassembled (yay, i have a front sway bar again)

-reassembly of the forward body panels has begun

The next step is to complete the intake charge piping, install the radaitor fans and associated bracketry, and plumb the cooling system. I already have the majority of the materials required, so that shouldn't take too long. After that, it's just a matter of changing the oil, installing the plugs, and installing the down pipe.

I leave you with a few pictures....

Attachments

Last edited: