That is so weird. I figured that it would have the extra area below 5200 for pulse charging, then close it off above 5200 to keep the velocity up. I was thinking that I would make it switch over at 0 psi to give a straight shot to the valves. Oh well, that sucks. Thanks for the heads up.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

VICS Sucks!!!!

- Thread starter TurfBurn

- Start date

Protege_Speed

Member

- :

- 2002.5 ES Auto with MSP Conversion

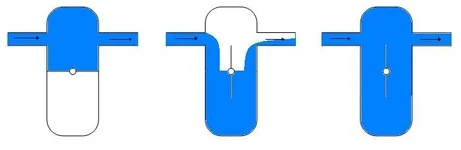

Thanks for the explaination. I think understand the whole VE thing now. That's pretty much what I was thinking which leads me to my next point about the VICS. Since I am not blowing in enough air into the engine already with the VICS closed, when the VICS opens and there is a larger plenum that needs to be filled, doesn't that slow up the velocity and volume of the air going into the engine until it gets equalized? I guess what I am trying to say is, the pressure of air in the intake manifold is as at a certain level up until the VICS opens and when it does, the pressure then drops until it's equalized again. But in our NA cars, we just don't blow that much as FI cars to fill the plenum thus never getting back to the 80% filling you mentioned. I guess another example would be if you take a water hose and attach it to a container that has a partition in it splitting it in half and also has an opening at the other end. You turn on the water and the container fills up first before it comes out the other opening. If you leave the water running, there will be a constant flow of water out the other end. Now if you suddenly remove the partition, the flow of water out the other opening will slow down until the whole container is filled with water again. Did that make sense? I added a drawing of what I meant. If I could figure out which one is the vics actuator and to keep it from opening, I will try it and see if my AFR changes.

As far as the MPI, I believe it is pulling the fuel because in first gear you can see the AFRs go up around 15 but it has no effect once I go into second and get passed 5200. Could this just be the ECU going into open loop and the VICS has nothing to do with it?

As far as the MPI, I believe it is pulling the fuel because in first gear you can see the AFRs go up around 15 but it has no effect once I go into second and get passed 5200. Could this just be the ECU going into open loop and the VICS has nothing to do with it?

Attachments

So I just want to clarify without beating it to death. I found this photo of the VICS valve system from a Miata head. I assume they work the same way.

http://members.aol.com/solomiata2/99intakeManifold.jpg

So:

Under 5200 rpm: The solenoid is activated (12V relay) by power from the ECU allowing vacuum from the manifold to pull the VICS valves shut (ie - block off the extra runner volume)

Above 5200 rpm: The solenoid is deactivated (the solenoid valve is normally closed, blocking vacuum [open circuit]) allowing a spring to open the VICS valves and reveal the extra runner volume.

To summarize: below 5200 rpm there is less runner volume than above 5200 rpm.

http://members.aol.com/solomiata2/99intakeManifold.jpg

So:

Under 5200 rpm: The solenoid is activated (12V relay) by power from the ECU allowing vacuum from the manifold to pull the VICS valves shut (ie - block off the extra runner volume)

Above 5200 rpm: The solenoid is deactivated (the solenoid valve is normally closed, blocking vacuum [open circuit]) allowing a spring to open the VICS valves and reveal the extra runner volume.

To summarize: below 5200 rpm there is less runner volume than above 5200 rpm.

Protege Speed---you can tune that out with the MPI. I would get in 3rd or 4th and tune that area. Then go to another gear and see what she does. If you can't get that, you can change you map and actually have it give MORE fuel the higher the load goes. That will require a bit of rework on the map, but is possible.

Protege_Speed said:Thanks for the explaination. I think understand the whole VE thing now. That's pretty much what I was thinking which leads me to my next point about the VICS. Since I am not blowing in enough air into the engine already with the VICS closed, when the VICS opens and there is a larger plenum that needs to be filled, doesn't that slow up the velocity and volume of the air going into the engine until it gets equalized? I guess what I am trying to say is, the pressure of air in the intake manifold is as at a certain level up until the VICS opens and when it does, the pressure then drops until it's equalized again. But in our NA cars, we just don't blow that much as FI cars to fill the plenum thus never getting back to the 80% filling you mentioned. I guess another example would be if you take a water hose and attach it to a container that has a partition in it splitting it in half and also has an opening at the other end. You turn on the water and the container fills up first before it comes out the other opening. If you leave the water running, there will be a constant flow of water out the other end. Now if you suddenly remove the partition, the flow of water out the other opening will slow down until the whole container is filled with water again. Did that make sense? I added a drawing of what I meant. If I could figure out which one is the vics actuator and to keep it from opening, I will try it and see if my AFR changes.

As far as the MPI, I believe it is pulling the fuel because in first gear you can see the AFRs go up around 15 but it has no effect once I go into second and get passed 5200. Could this just be the ECU going into open loop and the VICS has nothing to do with it?

The chamber is always full of air, so there is no lag time... it's just changing where the pressure waves bounce off of... whether they bounce off the butterflies or off the back of the chamber... so it kind of kills your theory... the butterflies leak just enough that that chamber will always be full of air... and any "recovery" time would be less than a millisecond... so that won't have any visible affect at all. The VICS actuator is the one that has an arm that goes to the middle of the intake rather than the other actuator that goes to right where the head and intake manifold meet... they are the two big brass weird looking things on the passenger side of the manifold.

Spooled said:So I just want to clarify without beating it to death. I found this photo of the VICS valve system from a Miata head. I assume they work the same way.

http://members.aol.com/solomiata2/99intakeManifold.jpg

So:

Under 5200 rpm: The solenoid is activated (12V relay) by power from the ECU allowing vacuum from the manifold to pull the VICS valves shut (ie - block off the extra runner volume)

Above 5200 rpm: The solenoid is deactivated (the solenoid valve is normally closed, blocking vacuum [open circuit]) allowing a spring to open the VICS valves and reveal the extra runner volume.

To summarize: below 5200 rpm there is less runner volume than above 5200rpm.

Yes.. spot on.

- :

- Hemi Ram, 71 Plymth Scamp, 71 Plymth Duster 340, 69 Dart 340/4sp

The vacuum chamber in the intake manifold, which is fed by a one-way check valve under the top half of the intake manifold.

I know. Let me try to rephrase.BlkZoomZoom said:The vacuum chamber in the intake manifold, which is fed by a one-way check valve under the top half of the intake manifold.

Ok, so say the solenoid valve is open, and it is letting vacuum get from the chamber to the actuator. Now we close the solenoid. There is still vacuum in the chamber(ok that is expected), but there would also still be vacuum in the line going to the actuator, unless there is something letting new air in.

It's like you have a straw, and you put you finger over one end, and suck the other with your mouth until you feel it pulling on your finger. Then you pinch the middle of the straw...there is still a vacuum on your finger.

Finger = actuator

Mouth = chamber

Pinch = solenoid

Protege_Speed

Member

- :

- 2002.5 ES Auto with MSP Conversion

I gotcha. Thanks. I wonder if there is a way to just get the actuator to open the VICS when you are at WOT or when you want it to open instead of at 5200. Too bad I can't do this with the MPI.

TurfBurn said:The chamber is always full of air, so there is no lag time... it's just changing where the pressure waves bounce off of... whether they bounce off the butterflies or off the back of the chamber... so it kind of kills your theory... the butterflies leak just enough that that chamber will always be full of air... and any "recovery" time would be less than a millisecond... so that won't have any visible affect at all. The VICS actuator is the one that has an arm that goes to the middle of the intake rather than the other actuator that goes to right where the head and intake manifold meet... they are the two big brass weird looking things on the passenger side of the manifold.

Protege_Speed

Member

- :

- 2002.5 ES Auto with MSP Conversion

I tried taking a ton of fuel out and it still happened. So you're saying that I should try dumping more fuel in instead? Why would that work?

Bigg Tim said:Protege Speed---you can tune that out with the MPI. I would get in 3rd or 4th and tune that area. Then go to another gear and see what she does. If you can't get that, you can change you map and actually have it give MORE fuel the higher the load goes. That will require a bit of rework on the map, but is possible.

- :

- MP5T / 944

Just remove it and you will get rid onf the "Part Injestion" problem and get more air at the same time.

Excuse this if someone has explained it that way before, but I couldn't find an explaination of exactly how it works.

This is the only thing that would make sense to me. The extra chamber is more for pulse tuning, which I would think makes more sense for N/A applications than F/I. Most people know that there are intake pulses that are causes but the intake valves opening and closing (accelerating and decelerating the speed of the intake charge). So I assume that the extra chamber is designed to make the intake pulses line up with the timing of the intake valves o keep the charge inertia up. I can see why having a cleaner intake manifold would be great for MSPs since those pulses don't mean crap once the turbo starts spooling.

So basically I think that it has less to do with airflow/air column length an more to do with the rhythm of the intake pulses.

This is the only thing that would make sense to me. The extra chamber is more for pulse tuning, which I would think makes more sense for N/A applications than F/I. Most people know that there are intake pulses that are causes but the intake valves opening and closing (accelerating and decelerating the speed of the intake charge). So I assume that the extra chamber is designed to make the intake pulses line up with the timing of the intake valves o keep the charge inertia up. I can see why having a cleaner intake manifold would be great for MSPs since those pulses don't mean crap once the turbo starts spooling.

So basically I think that it has less to do with airflow/air column length an more to do with the rhythm of the intake pulses.

Spooled said:Excuse this if someone has explained it that way before, but I couldn't find an explaination of exactly how it works.

This is the only thing that would make sense to me. The extra chamber is more for pulse tuning, which I would think makes more sense for N/A applications than F/I. Most people know that there are intake pulses that are causes but the intake valves opening and closing (accelerating and decelerating the speed of the intake charge). So I assume that the extra chamber is designed to make the intake pulses line up with the timing of the intake valves o keep the charge inertia up. I can see why having a cleaner intake manifold would be great for MSPs since those pulses don't mean crap once the turbo starts spooling.

So basically I think that it has less to do with airflow/air column length an more to do with the rhythm of the intake pulses.

Your explanation of how it works is correct... however what is incorrect is that the FI cars do benefit from it... if you look at my dyno sheets they are at 10 psi comparing the VICS closed and the VICS open... with it open ("activated") there is more power by a LARGE margin... so that extra chamber helps... no what it does down low I don't know, and in an FI car I do agree it is more useless down low as we typically have enough boost to compensate for any lack of power around 3000 rpm's.... so yeah... I left the actuator on the side, and the butterflies in the manifold, but removed all of the solenoids and wiring.

Protege_Speed said:I tried taking a ton of fuel out and it still happened. So you're saying that I should try dumping more fuel in instead? Why would that work?

Sorry man, I didn't post that correct. Try to LEAN out the fuel on the 1x16 column to pull fuel out the higher the load goes. Meaning, as the red cursor goes down, the load is increasing, lower the 1.00's to make it pull some of the excess fuel out.

This is kinda off topic, PM me if you need more help.

- :

- MP5T / 944

So removing the flaps is not a neagtive for FI cars...

Brian MP5T said:So removing the flaps is not a neagtive for FI cars...

I have to do more dynos to be sure... but as best as I can tell you do lose a little low end, but with FI you pick it up so fast with the turbo that it isn't really a detriment... and for those with traction problems, shaving off a little early low end torque can be beneficial.

Later!

Steve

Our 2.0 fs powered probes dont have VICS. I do know of the v6 probes that have VICS (they call it VRIS). Alot of boosted members are claiming gains from Tying the butterflies open or removing them all together. Turf, i wish i had an extra manifold i could send yah. Id really like to see which is the best platform for boost.

Well I run mine with it left open the entire time, I don't ever let them close on my car.. so running it similar to how your guys do too... the manifold without the VICS would be interesting to check out though.. maybe i"ll test that this spring when I have some money again and go for another dyno...

Similar Threads and Articles

- Replies

- 8

- Views

- 565

- Replies

- 0

- Views

- 1K

New Posts and Comments

- Replies

- 10K

- Views

- 3M

- Replies

- 26

- Views

- 877

- Replies

- 247

- Views

- 51K

- Replies

- 55

- Views

- 40K

- Replies

- 0

- Views

- 49