Since my neighbor's son was around, had him think over the issues with the car. His first comment was on how slow the starter was turning over. His thought was to check cyl compression. Went and rented the tool. Numbers certainly don't look good. #1 and #4 had around 25lbs while the other two had none. Screwed in the hose as best as I could, not certain if I should even go by those numbers. Either the starter is going so slow, it just doesn't give the proper numbers, or the timing is off and valves are open and not allowing compression. Driving me up a wall....

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

No fire under the hood

- Thread starter scottma

- Start date

One other really bad scenario is that your belt skipped some teeth and you bent a bunch of valves.

It does happen but it is still quite rare.

Maybe check your valve clearances to see if any are way out of spec.

If a valve is bent it doesn't seat all the way and the clearance is huge.

Your crank timing may not be what it's saying on the timing cover so your pistons could be way out of whack with the valves.

Removing your crank pulley and timing belt cover to get to the T-belt gear to get an accurate reading might be your next step.

You may find that your actual crank timing is off by something like 90 or something crazy.... That could explain the lack of compression.

It does happen but it is still quite rare.

Maybe check your valve clearances to see if any are way out of spec.

If a valve is bent it doesn't seat all the way and the clearance is huge.

Your crank timing may not be what it's saying on the timing cover so your pistons could be way out of whack with the valves.

Removing your crank pulley and timing belt cover to get to the T-belt gear to get an accurate reading might be your next step.

You may find that your actual crank timing is off by something like 90 or something crazy.... That could explain the lack of compression.

This is a quote from another recent thread...

"The FSDE is absolutely interference. I've seen the result of this first hand countless times.

The clearest example I could give is this:

I once watched the timing belt jump on a protege AT IDLE. It instantly bent all 16 valves and lost all compression."

Thinking about this makes me wonder if the valves were all bent or if resetting the timing belt would have restored compression ??

"The FSDE is absolutely interference. I've seen the result of this first hand countless times.

The clearest example I could give is this:

I once watched the timing belt jump on a protege AT IDLE. It instantly bent all 16 valves and lost all compression."

Thinking about this makes me wonder if the valves were all bent or if resetting the timing belt would have restored compression ??

I've only owned the P5 for less than a couple of months now. Not really enough time to get used to the oddities it may have. When I took the starter down to have it tested, one tech that wasn't even involved with the testing came over and stated how slow it is. Left the charger on a couple of nights, the starter still goes slow. Today, put the charger at the 50amp setting, even jumped it from my neighbors car, still the same slow starter. By going by my past experiences with vehicles (I'm 56 - been turning wrenches since my dad handed them to me since who knows when), this is the slowest starter I've ever been around. Guess I need to wait for the kit to arrive and start the tear down.

When the motor died on the road, never heard any loud bangs. Turning the motor over while trying to figure this out, still don't hear any odd noises that tell me that the pistons / values are hitting. At least that's my hope...

When the motor died on the road, never heard any loud bangs. Turning the motor over while trying to figure this out, still don't hear any odd noises that tell me that the pistons / values are hitting. At least that's my hope...

I'm at a loss as to why you apparently have no compression.

If you do in fact have bent valves, it'd be nice to know before you put any new parts on it so you can send the kit back for a refund.

Or at least know where you stand so you could score a used cylinder head off a junker for no too much money.

As far as the starter motor goes, if it started your car before the incident then it should start it after your engine is fixed.

If you do in fact have bent valves, it'd be nice to know before you put any new parts on it so you can send the kit back for a refund.

Or at least know where you stand so you could score a used cylinder head off a junker for no too much money.

As far as the starter motor goes, if it started your car before the incident then it should start it after your engine is fixed.

Going to check value clearance tonight. Hoping that the values are not stuck. Thinking this way since there is no noise/bangs/etc when turning the motor over.

Will do the TDC test also..

And agree with your last statement, it started before with this setup, should start now.

Put the charger on the batt last night, left it on this morning so it should have a good 20 hour charge on it..

Will do the TDC test also..

And agree with your last statement, it started before with this setup, should start now.

Put the charger on the batt last night, left it on this morning so it should have a good 20 hour charge on it..

What about tearing down your engine and checking the timing according to the engine markings and resetting your original belt. (if it isn't all shredded and your tensioner spring isn't stretched) and just see if it will start or at least get some compression.

You shouldn't even have to install your crank pulley or accessory belts to start it.

If it starts, then install the new timing kit and call it fixed.

If not, then install your timing kit on your new JDM motor because it is most likely due for a change and it's way easier to install with the engine out.

You shouldn't even have to install your crank pulley or accessory belts to start it.

If it starts, then install the new timing kit and call it fixed.

If not, then install your timing kit on your new JDM motor because it is most likely due for a change and it's way easier to install with the engine out.

- :

- protege5

I still think you skipped a tooth, probably on the crank. The first time my timing belt let loose it was all still intact, cams still lined up but didn't spin. So i was a little confused, until i removed it and saw where 12-13 of the teeth on the belt were completely stripped off of the belt at the crank pulley.

If yuou didn't hear any bad noises, then it's unlikely you have any internal damage. REmember, if the belt skips a tooth or few, it's out of time. and the valves won't be opening/closing at the correct times and you will have no compression that way. simply resetting the timing back to where it should be would restore compression in that case.

have you pulled the valve cover off to look at the belt at the top/cams? what kind of condition is the belt in?

I really think you've got a bad sensor, belt, or combination of the two. catastrophic engine damage, while possible, is highly unlikely without making quite a bit of noise. hell, even just the timing belt breaking sounds like a gunshot when it lets loose (more like a .22, not a shotgun, but still very noticeable) and you "feel" the break through the car as well. When mine broke the 2nd time, i was certain there was going to be a window into one of the cylinders by the way it felt. got it home, slapped a new belt and tensioner spring in it, and runs like new. almost 260k on it and still going strong as ever, there's just no "quit" in this thing

If yuou didn't hear any bad noises, then it's unlikely you have any internal damage. REmember, if the belt skips a tooth or few, it's out of time. and the valves won't be opening/closing at the correct times and you will have no compression that way. simply resetting the timing back to where it should be would restore compression in that case.

have you pulled the valve cover off to look at the belt at the top/cams? what kind of condition is the belt in?

I really think you've got a bad sensor, belt, or combination of the two. catastrophic engine damage, while possible, is highly unlikely without making quite a bit of noise. hell, even just the timing belt breaking sounds like a gunshot when it lets loose (more like a .22, not a shotgun, but still very noticeable) and you "feel" the break through the car as well. When mine broke the 2nd time, i was certain there was going to be a window into one of the cylinders by the way it felt. got it home, slapped a new belt and tensioner spring in it, and runs like new. almost 260k on it and still going strong as ever, there's just no "quit" in this thing

Last edited:

- :

- protege5

^^^ What he said.

Considering the time, labor and expense of putting in a JDM motor, it's well worth your time to verify your timing, correct it and see what happens.

Plus your original problem was no spark. you don't need compression to have spark!

Aside from that, i've gone the JDM route in the past with another car. I'll never do that again... with the time/$$$ to go that route you're better off having your old motor rebuilt. Few hundred bucks in parts (bearings, rings, seals, gaskets, etc), few hundred bucks in machine work (if necessary... usually just a quick hone job in the cylinders is all that's necessary unless there's damage/major scoring) and you're back up and running with basically a brand new/0 mile motor. If you look inside the motor, there really aren't that many moving parts that need to be replaced in a rebuild. CRankshaft is usually fine unless scored from oil deprivation. pistons are usually fine unless damaged. valves are usually fine unless bent, just verify clearances and re-lap them, though i would replace the valve springs and seals. I'll take that any day over a motor with unknown mileage, maintenance history, etc that gets shipped from overseas on a crate. IF you're going for a few extra HP in the JDM then whatever floats your boat. But if you're just looking to make the car run again so it's a reliable driver, i'd rebuild the engine already in it without hesitation. Much more reliable that way long term.

Last edited:

Plus your original problem was no spark. you don't need compression to have spark!...

No,.. His car always had spark.

I was saying that his crank sensor was working because if it wasn't he wouldn't have spark.

I'm thinking now that his valve timing simply must be off to have no compression.

There's simply no other explanation for a spontaneous lack of compression.

So if he resets his timing and it still won't run then it must be a sensor as well.

I only wonder how many teeth the belt needs to skip to leave no compression,...... Maybe even one tooth on the crank is enough ??

- :

- protege5

No,.. His car always had spark.

I was saying that his crank sensor was working because if it wasn't he wouldn't have spark.

I'm thinking now that his valve timing simply must be off to have no compression.

There's simply no other explanation for a spontaneous lack of compression.

So if he resets his timing and it still won't run then it must be a sensor as well.

I only wonder how many teeth the belt needs to skip to leave no compression,...... Maybe even one tooth on the crank is enough ??

Very good question. Guess it depends on how tight the engine tolerances are on this motor.

But agreed, total loss of compression instantly on 1 cylinder is feasible. But total loss of compression on all 4 cylinders at the same time, with no clatter or bang/pow/boom is very highly unlikely.

IIRC, there are timing marks on the backside of the cam gears and you can look straight across the engine from the other side and eye them up much easier than staring down into the engine bay.

I checked my parts car for reference but the cam gears (and maybe cam too ??) Must have been replaced or something and the marks are dots instead and they're not marked on the backside.

OK,.. So it was getting dark out and I was getting quite drunk and didn't see all the marks on the cam sprockets.

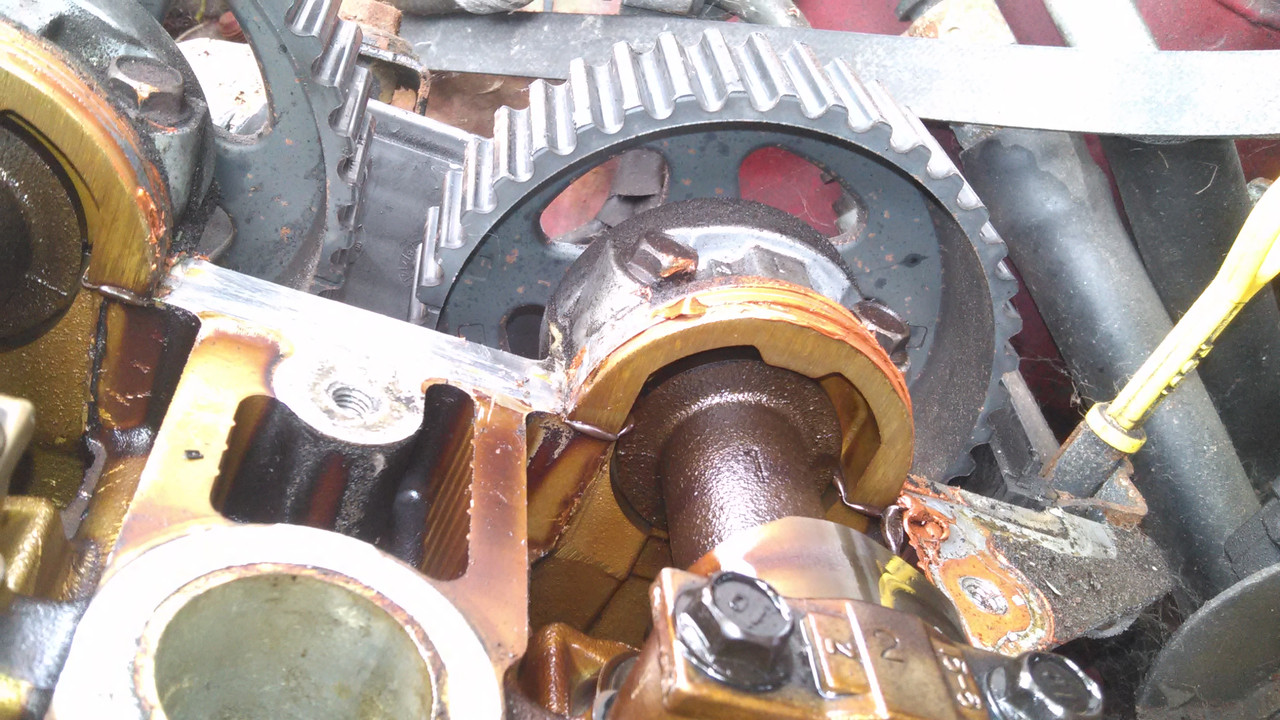

They look like this on the backside from the drivers side...

Real easy to line up...

Interestingly, the cams wanted to "spring" left or right but if I held them, lined up, they would stay lined up after I let go. ... But the car has been sitting for three years so there's probably lots of rusty friction.

Last edited:

Well, the story continues. Timing is fine (bang) With that, called the gent that recently bought my Jeep. He owns a auto repair shop. Told him everything I know and done so far. His first words were, check the anti-freeze. Yep, empty.. He figures the motor overheated, either warped the head or cracked the block. I did check the level when I purchased it and it was at the top. So the problem is deeper than just skipped timing. Car is heading to his shop on Monday for a motor replacement. I've never done a fwd motor swap and really no place to do the work anyway. I've swapped out the motor in the Jeep twice, pulled motors in other rwd vehicles. It's not that I don't want to try, space and time are two factors why it's going to a shop. Plus the fact I'm getting tired of riding the V-Star in the rain...

New Posts and Comments

- Replies

- 1

- Views

- 53

- Replies

- 10K

- Views

- 1M