Progress!

Okay, not really but you have to start somewhere, right? Got the rear end in the air and started pulling things off between studying for exams and doing house stuff.

Before I can get to any of the drivetrain about 1/2 the exhaust has to come out. Despite being 21 years-old and rusty as hell, none of the bolts gave me any grief. The big alumimum thing is the exhaust heat shield for the differential.

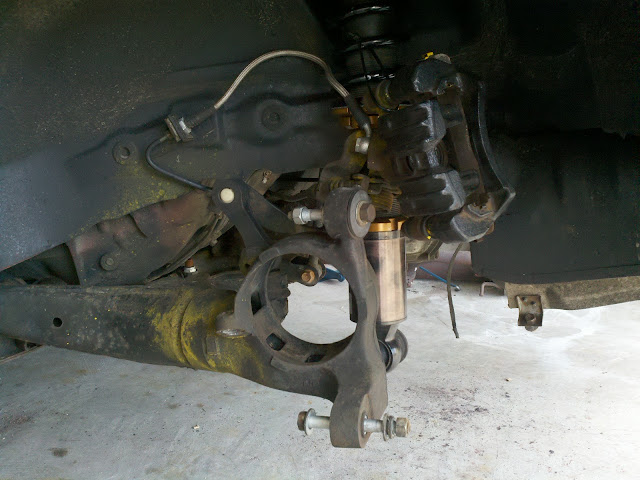

So here's what has to come out. I think I this point I had just finished marking everything (so everything can go back together correctly).

At this point I turned to the hubs as they'll need to come off before removing the control arms. I'll also be replacing the lower bushing (hidden) with a delrin insert to elmininate the rear steering feature (more on that next). Yes, the brake caliper is hanging from the coil spring via zip tie, LOL!

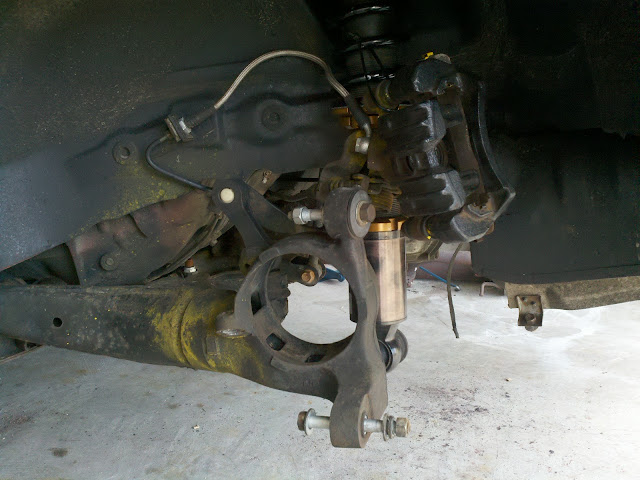

This is as far as I've made it today (need to study!). Rear hubs and CV shafts removed. It turns out both rear steer bushings were completely shot so they fell apart as soon as everything was unbolted so I suppose it's a good thing they're being replaced.

Next will be the control arms and then I need to figure out how to lower the subframe/differential assembly (80+ lbs). Hopefully I'll have everything remove tomorrow so then I can start replacing bushings and swapping the differential cover.

That's all for now - need to go study so an entire quarter of graduate classes (and the associated cost) doesn't go to waste!

Okay, not really but you have to start somewhere, right? Got the rear end in the air and started pulling things off between studying for exams and doing house stuff.

Before I can get to any of the drivetrain about 1/2 the exhaust has to come out. Despite being 21 years-old and rusty as hell, none of the bolts gave me any grief. The big alumimum thing is the exhaust heat shield for the differential.

So here's what has to come out. I think I this point I had just finished marking everything (so everything can go back together correctly).

At this point I turned to the hubs as they'll need to come off before removing the control arms. I'll also be replacing the lower bushing (hidden) with a delrin insert to elmininate the rear steering feature (more on that next). Yes, the brake caliper is hanging from the coil spring via zip tie, LOL!

This is as far as I've made it today (need to study!). Rear hubs and CV shafts removed. It turns out both rear steer bushings were completely shot so they fell apart as soon as everything was unbolted so I suppose it's a good thing they're being replaced.

Next will be the control arms and then I need to figure out how to lower the subframe/differential assembly (80+ lbs). Hopefully I'll have everything remove tomorrow so then I can start replacing bushings and swapping the differential cover.

That's all for now - need to go study so an entire quarter of graduate classes (and the associated cost) doesn't go to waste!