You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mazda5 BC Racing BR Type Coilovers - Review and Install

- Thread starter phunky.buddha

- Start date

Vortexblue

Member

- :

- mazda5 and som miatae

From years of working on VW's, this knuckle/ strut pinch area looks just like a mk4 VW.

There is a tool to spread that gap open, it's like magic for this job:

http://www.autotech.com/product/tools-bushings/10-012-411.html?fromcat=

I'm not sure the slot is the same size, but it sure looks like it. My wife's Maz5 and my toolbox are rarely in the same spot; but if they are, I'll test for you.

Hope this helps.

There is a tool to spread that gap open, it's like magic for this job:

http://www.autotech.com/product/tools-bushings/10-012-411.html?fromcat=

I'm not sure the slot is the same size, but it sure looks like it. My wife's Maz5 and my toolbox are rarely in the same spot; but if they are, I'll test for you.

Hope this helps.

phunky.buddha

Booga Booga?

- :

- DFW TX

- :

- No mo MZ5 want MX5

Not trying to be a necromancer on my own thread... but continuing after being MIA for a few months:

Royal pain in the ass. I honestly haven't adjusted mine since I installed them (got lucky), but I think you'd just about have to remove them and then adjust them off the car to do anything. I just spun mine out 4 turns (I think, it's in the writeup) after matching lengths and it was pretty much dead on for -1.5 degrees of rear camber after the drop.

Yup. BFH is good stuff.

Sweet! I want one of those!

Op how hard is to adjust rear camber with the aftermarket arms when they are installed on the car

Royal pain in the ass. I honestly haven't adjusted mine since I installed them (got lucky), but I think you'd just about have to remove them and then adjust them off the car to do anything. I just spun mine out 4 turns (I think, it's in the writeup) after matching lengths and it was pretty much dead on for -1.5 degrees of rear camber after the drop.

Wow man. Your write up is on point. Thank you for posting. And yes, a BFH is your friend for this job.

Yup. BFH is good stuff.

From years of working on VW's, this knuckle/ strut pinch area looks just like a mk4 VW.

There is a tool to spread that gap open, it's like magic for this job:

http://www.autotech.com/product/tools-bushings/10-012-411.html?fromcat=

I'm not sure the slot is the same size, but it sure looks like it. My wife's Maz5 and my toolbox are rarely in the same spot; but if they are, I'll test for you.

Hope this helps.

sweet! that's one of those "i know it has to exist" tools

Sweet! I want one of those!

bracedeunos

Member

- :

- 91 Miata, 88 323 GTX, 06 Mazda5, 05 Mazda MPV

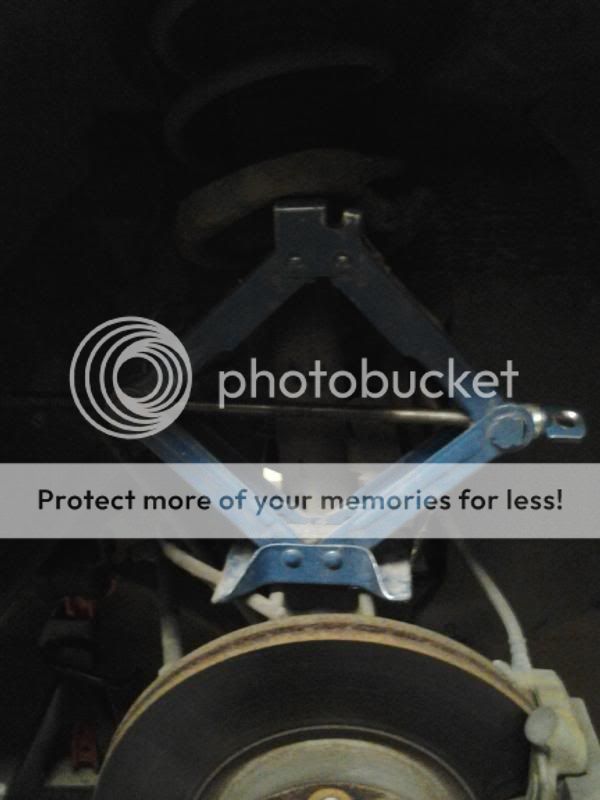

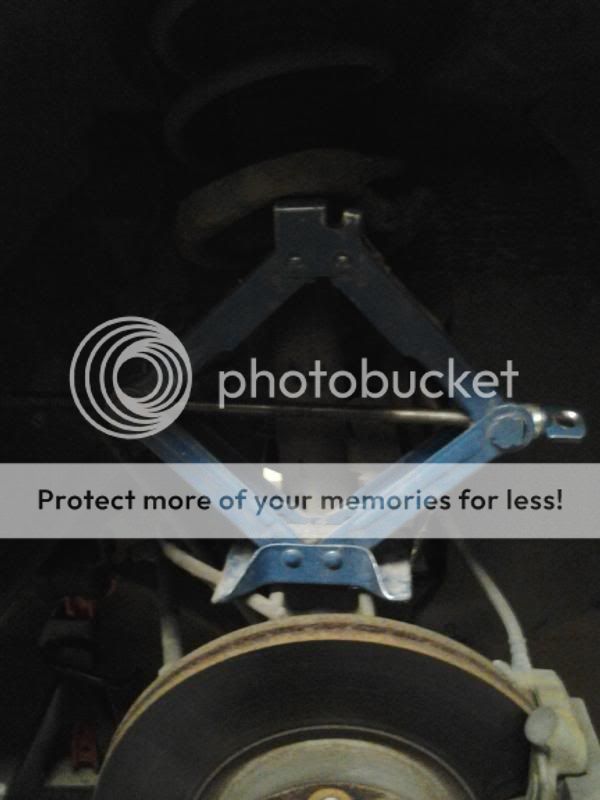

FYI.....when removing the OE strut from the Hub/Spindle let your tools do the work for you. Instead of using a hammer and spending time banging on the hub use a scissor jack to force the strut from the seating position on the collar. Like so:

phunky.buddha

Booga Booga?

- :

- DFW TX

- :

- No mo MZ5 want MX5

FYI.....when removing the OE strut from the Hub/Spindle let your tools do the work for you. Instead of using a hammer and spending time banging on the hub use a scissor jack to force the strut from the seating position on the collar. Like so:

Trust me, I tried- no matter how I crammed the jack in or shimmed it with wood or anything else, the jack kept slipping out.

rodslinger

Member

Trust me, I tried- no matter how I crammed the jack in or shimmed it with wood or anything else, the jack kept slipping out.

There is a slightly easier way. When you take out the bolt securing the strut to the knuckle, reinstall the bolt on the other side of the strut. Before threading it back in, slip a quarter in the slot on the bottom side of the strut blocking the bolt from going all the way through. When you tighten the bolt down the quarter will push open the knuckle enough to let the strut easily slip out. You'll sacrifice a quarter or two but it sure makes life easier.

phunky.buddha

Booga Booga?

- :

- DFW TX

- :

- No mo MZ5 want MX5

There is a slightly easier way. When you take out the bolt securing the strut to the knuckle, reinstall the bolt on the other side of the strut. Before threading it back in, slip a quarter in the slot on the bottom side of the strut blocking the bolt from going all the way through. When you tighten the bolt down the quarter will push open the knuckle enough to let the strut easily slip out. You'll sacrifice a quarter or two but it sure makes life easier.

Very true- and I've done it that way on other cars before, don't know why I didn't think to do it this time. I'll amend the writeup in a bit.

phunky.buddha

Booga Booga?

- :

- DFW TX

- :

- No mo MZ5 want MX5

Edited the writeup to include links to both of your easier strut fork removal methods in here, and hung your names in the post too. Thanks!

- :

- 2008 Mazda5 GT

Thanks. That's a great idea! But why suggest wasting a quarter when a nickel is cheaper (and thicker)There is a slightly easier way. When you take out the bolt securing the strut to the knuckle, reinstall the bolt on the other side of the strut. Before threading it back in, slip a quarter in the slot on the bottom side of the strut blocking the bolt from going all the way through. When you tighten the bolt down the quarter will push open the knuckle enough to let the strut easily slip out. You'll sacrifice a quarter or two but it sure makes life easier.

I've never had a difficult time removing struts on my previous cars but I think this car is an exception.

- :

- 2008 Mazda5 GT

When doing my turbo, I spent about 30 minutes trying to get the stock manifold out, with the cowl still installed.

Spent 5 minutes removing the cowl, and the manifold was out minutes later.

I bet the 5 minutes to remove the cowl was totally worth it in this situation also.

So much more room to work!

Spent 5 minutes removing the cowl, and the manifold was out minutes later.

I bet the 5 minutes to remove the cowl was totally worth it in this situation also.

So much more room to work!

Finally replaced my front struts thanks to the OP's how-to. Although I did replace mine with just the standard OE by Monroe; the "Quick-Strut" type so I didn't have to finagle with the springs. Also, +1 on the scissor jack method to separate the strut from the knuckle. There is a certain angle that the jack will stay put. Once that's established it's all gravy from that point on..

Last edited:

crazyp8ntr

Member

- :

- Mazda5

Thank you so much for this great write-up and pictures. I used it this weekend to install a set of Raceland Primo coilovers.

Thanks. That's a great idea! But why suggest wasting a quarter when a nickel is cheaper (and thicker).

FYI: this is against the law and carries fine and/or up to 5 year term: Title 18, Chapter 17 of the U.S. Code

Perhaps a washer of similar size purchased for a quarter is a better item to use

phunky.buddha

Booga Booga?

- :

- DFW TX

- :

- No mo MZ5 want MX5

Thank you so much for this great write-up and pictures. I used it this weekend to install a set of Raceland Primo coilovers.

You're very welcome

phunky.buddha

Booga Booga?

- :

- DFW TX

- :

- No mo MZ5 want MX5

Oh noooooes came back here to check something and saw all the pics were gone. Is anyone still using this? Can probably upload somewhere (preferably here) to get everything working again, but it'll take some time...

Oh noooooes came back here to check something and saw all the pics were gone. Is anyone still using this? Can probably upload somewhere (preferably here) to get everything working again, but it'll take some time...

I’d appreciate if they came back as I’m getting ready to do mine. Pretty sure I can mull my way through based on descriptions, but pictures are always nice.

New Posts and Comments

- Replies

- 0

- Views

- 9

- Replies

- 12

- Views

- 903

- Replies

- 0

- Views

- 52

New Threads and Articles

-

-

2017~2025 2021 CX-5 CE AWD - Instrument Cluster Swap/Upgrade?

- By brent99

- Replies: 0

-