You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Problems with built motor

- Thread starter kyle's protege5

- Start date

kyle's protege5

Member

- :

- 2002 MP5-T

Pistons should go one way only...youe may notice it by the size of the valve relief and in the piston skirt, the clearance for the squirters

i'm gonna have to look closer then, i do see the cutout you are talking about in your pic.

kyle's protege5

Member

- :

- 2002 MP5-T

Ah...one more thing. ''

With the Pauter rods...you WILL NEED to shave a bit off the cylinder skirt...or the rods will hit the bottom of them

Sorry I Dont have a pic of whats needed to be done.

i'll tear everything out and take a pic of where i think i should grind and you tell if its right, is that cool?

kyle's protege5

Member

- :

- 2002 MP5-T

Well I determined why the motor was easy then hard to turn. Its a pretty damn obvious one too. When the pistons are top or bottom, the valves are mostly closed or open. So its easy to turn the crank.

When the valves are opening, its obviously harder to turn the crank, cause its pushing them all open.

I confirmed this by turning the cams over individually when the head was off and they are easy, then hard. Easy, then hard.

When the valves are opening, its obviously harder to turn the crank, cause its pushing them all open.

I confirmed this by turning the cams over individually when the head was off and they are easy, then hard. Easy, then hard.

Loading up pics right now!pics pics pics pics!!!!!

Last edited:

kyle's protege5

Member

- :

- 2002 MP5-T

Here are the pics. You can see the marks on the rods in one, and in another you can see the yellow paint I put on it to see if it was rubbing. As you can see the paint is still on so its obviously not rubbing there.

In the pic of the cylinder skirt, I put an arrow on where I believe I need to grind. Is this 100% for sure that i have to do this? There is a lot more to take off and then clean the heck out of the block to make sure there are no shavings in there, if i have to grind this.

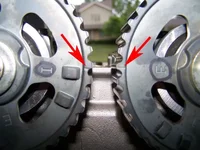

And the last pic is of the cam gears, I'm sure i'm right on this just want to double check that these are the marks that are supposed to be pointed at each other. I'm not taking any chances this time.

In the pic of the cylinder skirt, I put an arrow on where I believe I need to grind. Is this 100% for sure that i have to do this? There is a lot more to take off and then clean the heck out of the block to make sure there are no shavings in there, if i have to grind this.

And the last pic is of the cam gears, I'm sure i'm right on this just want to double check that these are the marks that are supposed to be pointed at each other. I'm not taking any chances this time.

Attachments

well if that was me I would try and contact someone about shaving the bottom of the cylinder before going balls out. if you had to I would personally break the block down to nothing, then shave it and then go get the block hot washed (dipped) to get any and I mean ANY shavings the **** out of there. now ( I know I know) is not the time to cut corners. do you really want to do this a third time???

if you ask me ( ive only rebuilt these motors a couple of times) it seems that you jumped the gun on this one and all you should have done is go and get another battery first before going this far..... sorry but it looks fine to me, gots clearance fer the sqirters, rods, pistion skirts, "cylinder skirts". cant amagin that forged goodies flex that much at 7.5K and under.

waits to be corrected........

if you ask me ( ive only rebuilt these motors a couple of times) it seems that you jumped the gun on this one and all you should have done is go and get another battery first before going this far..... sorry but it looks fine to me, gots clearance fer the sqirters, rods, pistion skirts, "cylinder skirts". cant amagin that forged goodies flex that much at 7.5K and under.

waits to be corrected........

And the last pic is of the cam gears, I'm sure i'm right on this just want to double check that these are the marks that are supposed to be pointed at each other. I'm not taking any chances this time.

dead on up top. how about below?

kyle's protege5

Member

- :

- 2002 MP5-T

Igdrasil has been pretty knowledgable, so i'm hoping he'll chime in again. Kooldino have any opinions? And I agree about breaking down the block. Thats why i want to be sure that it has to be done before i do it. And hell no, I dont want to do this a third time!well if that was me I would try and contact someone about shaving the bottom of the cylinder before going balls out. if you had to I would personally break the block down to nothing, then shave it and then go get the block hot washed (dipped) to get any and I mean ANY shavings the **** out of there. now ( I know I know) is not the time to cut corners. do you really want to do this a third time???

It was for sure not just the battery. The motor was locked. It would not turn over till we got it out and on the stand. Then i had to smack a socket wrench pretty good to get it free.if you ask me ( ive only rebuilt these motors a couple of times) it seems that you jumped the gun on this one and all you should have done is go and get another battery first before going this far..... sorry but it looks fine to me, gots clearance fer the sqirters, rods, pistion skirts, "cylinder skirts". cant amagin that forged goodies flex that much at 7.5K and under.

I did jump the gun on this from the begining though. I should have spent more time asking a lot more questions before i started this internals stuff. This was a last minute decision, that was done when I was swapping out the atx for the mtx.

kyle's protege5

Member

- :

- 2002 MP5-T

*UPDATE*

Motor is back in, turns over great! 1 piston was in wrong, and the caps were backwards. I knew I should have just done it myself the first time.

Now if it would only start............

I have no idea WTF is up with that. I'm sure its something to do with the atx-mtx swap. Have to go over my wiring again. Man, this is gonna suck worse than pulling the motor.

Motor is back in, turns over great! 1 piston was in wrong, and the caps were backwards. I knew I should have just done it myself the first time.

Now if it would only start............

I have no idea WTF is up with that. I'm sure its something to do with the atx-mtx swap. Have to go over my wiring again. Man, this is gonna suck worse than pulling the motor.

Maxx Mazda

Contributor

- :

- Stock P5

What caps were backwards? It didn't score the crank did it?

kyle's protege5

Member

- :

- 2002 MP5-T

the rod caps were all on backwards. and no scoring. was only turned over by hand like 2-3x.What caps were backwards? It didn't score the crank did it?

kyle's protege5

Member

- :

- 2002 MP5-T

its dead on the mark.dead on up top. how about below?

Think the cams may be in wrong now. WTF. this is getting old. check here

http://www.mazdas247.com/forum/showthread.php?t=123679913

I couldnt get any answers wether to grind the block or not, so i just did it anyways. Not doing this all again.so no milling??

Maxx Mazda

Contributor

- :

- Stock P5

Posted the link in your other thread. If the cams are off your car won't even sound right when cranking. Hopefully he set up your head properly (valve clearances, etc) or you might be in for a world of trouble...

timming is correct. if you never messed with the head other than taking it off it should be fine. Most cams bought for this car are fine with stock clerances, unless its one of those custom GB crap cams.

start small, does it have spark, does it have fuel, did you pop a fuse along the way???

and pray to your god that you got all the milling shavings out.

start small, does it have spark, does it have fuel, did you pop a fuse along the way???

and pray to your god that you got all the milling shavings out.

Maxx Mazda

Contributor

- :

- Stock P5

Oh ya, check under the hood at your 30A IGN fuse. Mine was blown and it wouldn't start.

kyle's protege5

Member

- :

- 2002 MP5-T

ok this is kinda embarassing.

When I took off the valve cover, I noticed that none of the fuel injectors were plugged in. Plugged them in put valve cover back on, and what do ya know. Started right up. I'm glad it was something simple, even if it is kind of a dumbass mistake.

One oher thing. I drove it around last night, and then drove it to work this morning. Is it normal for it to burn a little smoke untill the rings are seated? Its just a little and only when you get on it a little. The guys at work said thats not uncommon for new rings especially crome moly ones. Is this true?

Now if i can just figure out why my Greddy EBC isnt working.....

at least its running!

When I took off the valve cover, I noticed that none of the fuel injectors were plugged in. Plugged them in put valve cover back on, and what do ya know. Started right up. I'm glad it was something simple, even if it is kind of a dumbass mistake.

One oher thing. I drove it around last night, and then drove it to work this morning. Is it normal for it to burn a little smoke untill the rings are seated? Its just a little and only when you get on it a little. The guys at work said thats not uncommon for new rings especially crome moly ones. Is this true?

Now if i can just figure out why my Greddy EBC isnt working.....

at least its running!

Similar Threads and Articles

- Replies

- 2

- Views

- 698

New Posts and Comments

- Replies

- 221

- Views

- 45K

2017~2025

CX-5 Rear Differential Failure

- Replies

- 67

- Views

- 4K

- Replies

- 0

- Views

- 68