TurfBurn said:Is our peak VE really that bad??? Ick... but yes your calculations are correct... in theory the .8 changes with the rpm's... so you'd need to replace it per the correct value at each rpm point that you calculate..

Yup.

Based on my dyno... the torque held from 4.25K to 5K and then fell off linearly to about 6.25 k.. I lost 8% torque through that range... my AFR's were pretty stable... so in theory there is roughly an 8% drop in VE from 4.25K to 6.25K and then it droped another 10% from 6.25 to 6.75K but that could have possibly been compensated for by timing too.. timing curve affects all this.. so again it's a really hard calculation to do at all accurately.

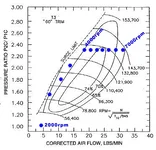

Sure, but for calculating efficiencies on the compressor maps, I would guess that the most important thing is to use the same CFM calculations to compare both maps.