Jack Rabbit

Banned

- :

- 18 Mazda CX5 AW

For anyone who needs to fix curb-rash or divots in a rim, the same process should work. please see below:

Bought Five(5) Mazda 16" rims for use on my CX-5 then had them sandblasted and powdercoated.

Powdercoater returned four(4) perfectly coated rims and one(1) rim that was deeply damaged by sandblaster then coated instead of fixed.

Whether the gouges & divots in the centerbore were from a corroded portion that was weak & sandblasted out

or

was from the sandblaster using incorrect hard media & too high sandblast pressure was questionable.

They should have contacted me to get the rim fixed properly with a pure aluminum alloy weld before powder-coating it.

But can only move forward!!

How to fix an expensive project wheel that is the fullsize spare wheel for off-road?

With Hypoxy Alumbond of course (similar to JB Weld Steel but JBWeld made no aluminum product).

Attached are pictures of the project from start to finish.

While not perfect, the fix is good enough.

Don't sand powdercoat as it already provides a better rough surface for adhesion than aluminum does. Painted rims probably need roughed up a bit.

Most important part - mix according to instructions in equal parts.

Applied Hypoxy Alumbond to fill in all divots and pits while trying to minimize a thick application.

Tip: drywall putty knife was too large for the small circular area. Used a plastic butter knife and the thinnest art knife to spread aluminum epoxy.

Let dry 24 hours then wet-sanded with 150 grit,

Used qtip(with ductape sandpaper) to get into any remaining crevices.

Was afraid the Dremel would take too much off and felt more comfortable handsanding.

Cleaned with tackcloth.

Applied 2nd coat to fill remaining pits of centerbore and let dry 24 hours.

Wet-sanded with 150 grit then 600 grit then 1000 grit.

Cleaned with rubbing alcohol then water.

Some of the Centerbore powdercoat was accidently sanded off. However as its only in the centerbore, may leave it as-is or may decide to paint.

Lastly the alumbond melt point is 250 ° F so safe for my use and most daily drivers. Unless you track the car, your rim shouldn't get over 170-180° F.

Bought Five(5) Mazda 16" rims for use on my CX-5 then had them sandblasted and powdercoated.

Powdercoater returned four(4) perfectly coated rims and one(1) rim that was deeply damaged by sandblaster then coated instead of fixed.

Whether the gouges & divots in the centerbore were from a corroded portion that was weak & sandblasted out

or

was from the sandblaster using incorrect hard media & too high sandblast pressure was questionable.

They should have contacted me to get the rim fixed properly with a pure aluminum alloy weld before powder-coating it.

But can only move forward!!

How to fix an expensive project wheel that is the fullsize spare wheel for off-road?

With Hypoxy Alumbond of course (similar to JB Weld Steel but JBWeld made no aluminum product).

Attached are pictures of the project from start to finish.

While not perfect, the fix is good enough.

Don't sand powdercoat as it already provides a better rough surface for adhesion than aluminum does. Painted rims probably need roughed up a bit.

Most important part - mix according to instructions in equal parts.

Applied Hypoxy Alumbond to fill in all divots and pits while trying to minimize a thick application.

Tip: drywall putty knife was too large for the small circular area. Used a plastic butter knife and the thinnest art knife to spread aluminum epoxy.

Let dry 24 hours then wet-sanded with 150 grit,

Used qtip(with ductape sandpaper) to get into any remaining crevices.

Was afraid the Dremel would take too much off and felt more comfortable handsanding.

Cleaned with tackcloth.

Applied 2nd coat to fill remaining pits of centerbore and let dry 24 hours.

Wet-sanded with 150 grit then 600 grit then 1000 grit.

Cleaned with rubbing alcohol then water.

Some of the Centerbore powdercoat was accidently sanded off. However as its only in the centerbore, may leave it as-is or may decide to paint.

Lastly the alumbond melt point is 250 ° F so safe for my use and most daily drivers. Unless you track the car, your rim shouldn't get over 170-180° F.

Attachments

-

1) mazda rim before powdercoat.png239.5 KB · Views: 74

1) mazda rim before powdercoat.png239.5 KB · Views: 74 -

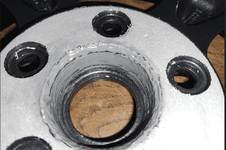

2) mazda wheel sandblast damage.png246.5 KB · Views: 71

2) mazda wheel sandblast damage.png246.5 KB · Views: 71 -

3) mazda wheel deeply gouged by sandblast.png222.6 KB · Views: 78

3) mazda wheel deeply gouged by sandblast.png222.6 KB · Views: 78 -

4) mazda rim 1st layer hypoxy alumbond.png276.7 KB · Views: 80

4) mazda rim 1st layer hypoxy alumbond.png276.7 KB · Views: 80 -

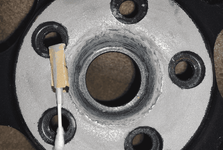

5) mazda 1st layer alumbond sanded.png227.1 KB · Views: 71

5) mazda 1st layer alumbond sanded.png227.1 KB · Views: 71 -

6) mazda rim sand first layer hypoxy alumbond.png369.4 KB · Views: 85

6) mazda rim sand first layer hypoxy alumbond.png369.4 KB · Views: 85 -

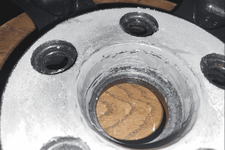

7) mazda 2nd layer alumbond.png292.5 KB · Views: 76

7) mazda 2nd layer alumbond.png292.5 KB · Views: 76 -

8) mazda rim fixed divots repaired and sanded.png277.6 KB · Views: 71

8) mazda rim fixed divots repaired and sanded.png277.6 KB · Views: 71 -

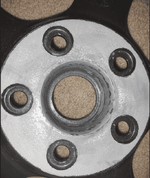

9) mazda rim divot repair final.png166.7 KB · Views: 66

9) mazda rim divot repair final.png166.7 KB · Views: 66

Last edited: