Jack Rabbit

Banned

- :

- 18 Mazda CX5 AW

Does powder coat = a weak rim??

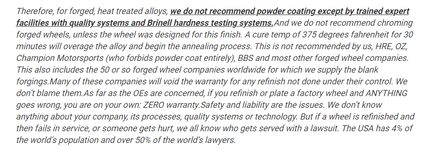

Apparently you need to be in charge of the whole powder-coating process from start to finish to make sure it's done right.

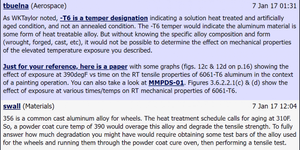

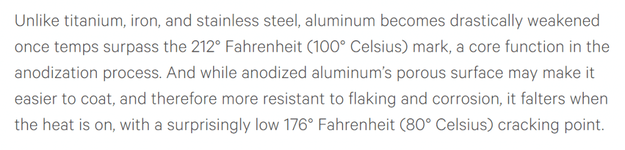

Supposedly high temperature over 200° can anneal & weaken some aluminum/alloy rims. And powder coats are usually baked on at 350 to 450° ... though there might be low temp powder coats out there.

But the shop could tell you one temp and bake it at another.

Also, some say sandblasting ruins the rims and causes microscopic cracks. Unless they blast with walnuts...apparently walnuts are safer.

Has anyone successfully ran powder-coated cast (low pressure cast) rims with no problems and no rim cracking, etc.?

Did they use walnut blasting and did they use low temp/bake powder coat ?

and were they OEM or aftermarket rims?

Just found out the local place doesn't use walnuts and they cook at 375°. At least it's not 450°. Heard 450° will completly destroy an alloy wheel.

And can't get bi-color rims or the machine flanged look. They only do one(1) color so need to make sure it's a color goes well with machine gray.

Apparently you need to be in charge of the whole powder-coating process from start to finish to make sure it's done right.

Supposedly high temperature over 200° can anneal & weaken some aluminum/alloy rims. And powder coats are usually baked on at 350 to 450° ... though there might be low temp powder coats out there.

But the shop could tell you one temp and bake it at another.

Also, some say sandblasting ruins the rims and causes microscopic cracks. Unless they blast with walnuts...apparently walnuts are safer.

Has anyone successfully ran powder-coated cast (low pressure cast) rims with no problems and no rim cracking, etc.?

Did they use walnut blasting and did they use low temp/bake powder coat ?

and were they OEM or aftermarket rims?

Just found out the local place doesn't use walnuts and they cook at 375°. At least it's not 450°. Heard 450° will completly destroy an alloy wheel.

And can't get bi-color rims or the machine flanged look. They only do one(1) color so need to make sure it's a color goes well with machine gray.

Last edited: