PrinceValorum

Member

- :

- 95 626 FS, 89 Toyota Derux 4x4

Tape a stress ball behind the gas pedal to provide resistance. (second)

Tape a stress ball behind the gas pedal to provide resistance. (second)

You could add a secondary spring from the cam on the back of your ITBs to a bracket. Look in the autoparts story for carb/throttle return springs or hit up the hardware store. It may not be a clean enough install for your setup but it is cheap and easy.

^ thats what i was gonna suggest...

Oh man, I'm going to send one of those shots to my phone, go hide in the bathroom and rub one out. Great job! Looks great! (2thumbs)

I googled it to be sure. Yuck! I still prefer boobies. haha

When do you think you'll get your triangles back and can start putting the motor together?

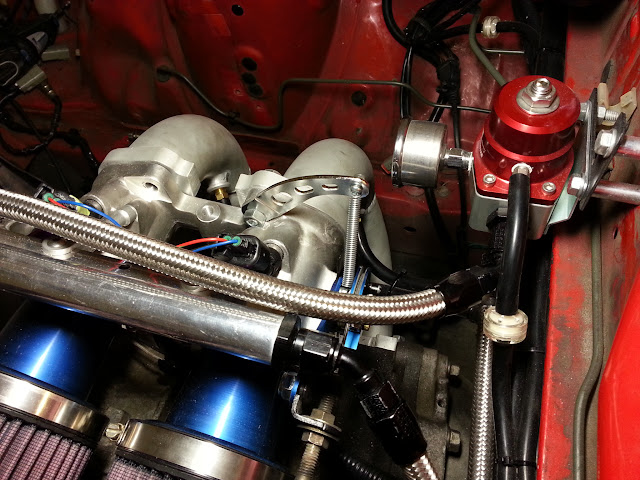

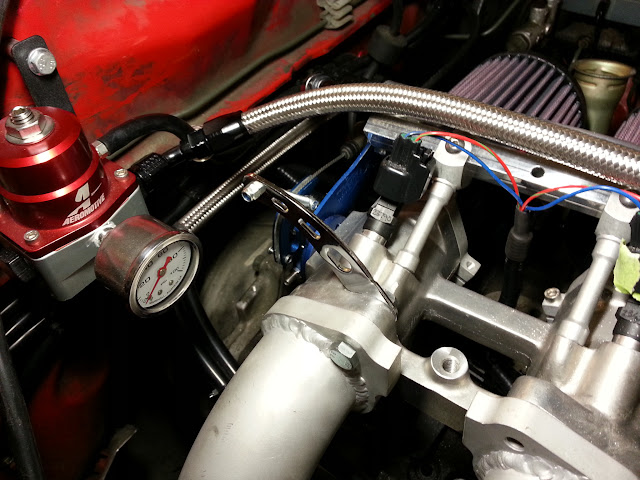

Hopefully Evan approves of the neatness. Here's another shot:

I had to make yet another bracket to hold the wires in place near the fuse box. I'm getting damn good with a hacksaw, table grinder, drill, and sandpaper.

Thanks!Looks awesome!