Since I've spent so much time building the GRM Challenger, necessity obligates me to add a bit more power to the CSP Miater. The 140k mile 1.6L has put up a fight, and a strong one indeed, but it just can't hang with the ranks of 1.8L Miatas that play along in CSP. She currently puts down over 100hp to the ground with a bone stock engine and a somewhat roughly tuned Megasquirt (currently working on a How To for that  ), but I digress.

), but I digress.

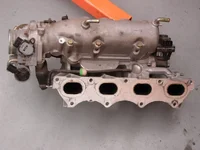

Inward steps the 1999 1.8L that I picked up today for $400 (120k miles with a new water pump, timing belt, etc). A hell of a deal if you ask me. Furthermore, a perfect catalytic converter was included for an extra $20 (stupid emissions). I've been urning to install one of these engines into the car for a couple of years. Furthermore, I have another '99 engine in the basement that awaits a rebuild (to tolerance and spec), but I haven't had the time to undertake that process. So when I came across this deal, I jumped on it. This engine will tide me over until I can fully rebuild the "spare" engine that currently remains parked downstairs.

As usual, business has me traveling for the next few weeks with an auto-x or two in between, so it'll be mid-April before this is installed. As with my previous build threads, I'll be posting plenty of pictures for those that are interested.

Without further ado, so begins the engine swap process

Inward steps the 1999 1.8L that I picked up today for $400 (120k miles with a new water pump, timing belt, etc). A hell of a deal if you ask me. Furthermore, a perfect catalytic converter was included for an extra $20 (stupid emissions). I've been urning to install one of these engines into the car for a couple of years. Furthermore, I have another '99 engine in the basement that awaits a rebuild (to tolerance and spec), but I haven't had the time to undertake that process. So when I came across this deal, I jumped on it. This engine will tide me over until I can fully rebuild the "spare" engine that currently remains parked downstairs.

As usual, business has me traveling for the next few weeks with an auto-x or two in between, so it'll be mid-April before this is installed. As with my previous build threads, I'll be posting plenty of pictures for those that are interested.

Without further ado, so begins the engine swap process

Attachments

Last edited: