Hi all,

I have a 2014 Mazda CX-5 GT 2.5L. I’ve owned it since new and have done oil changes every 5000km with factory filter and Mobil 1 5w30. The car has 170k km on it and has not had any major issues since I bought it.

Yesterday I noticed a knock when it was idling so I got my wife to bring it up to 2500-3000rpm and the video link is the result of that. Oil level is at the high mark.

I put it on a hoist this morning and removed the serpentine and water pump belt to rule out any of that and the knock remained. A stethoscope says it’s from the timing system somewhere.

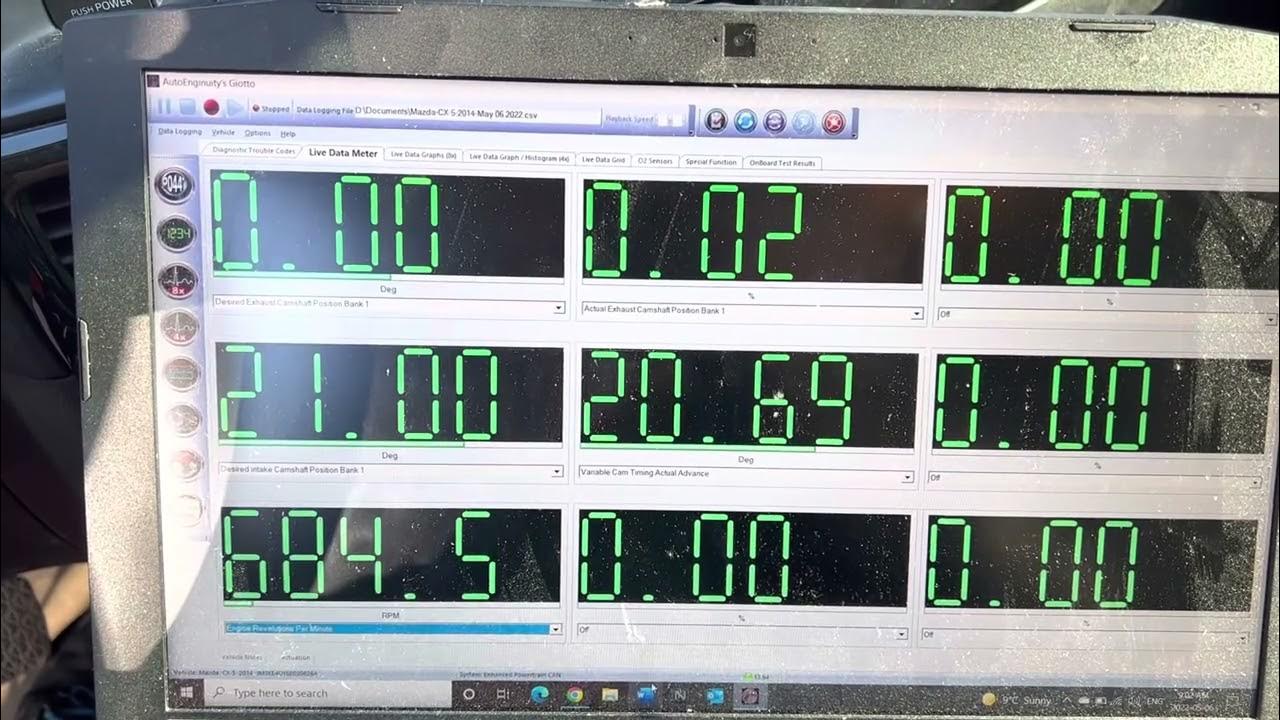

I’m not very familiar with the vvt system and am wondering if there’s any easy troubleshooting I can do to narrow down what part I need to change? I have a decent scan tool and I’m pretty sure I can actuate stuff with it. I’m pretty mechanically inclined and am not afraid to tear the engine apart.

Anyone here ever deal with this?

youtu.be

youtu.be

I have a 2014 Mazda CX-5 GT 2.5L. I’ve owned it since new and have done oil changes every 5000km with factory filter and Mobil 1 5w30. The car has 170k km on it and has not had any major issues since I bought it.

Yesterday I noticed a knock when it was idling so I got my wife to bring it up to 2500-3000rpm and the video link is the result of that. Oil level is at the high mark.

I put it on a hoist this morning and removed the serpentine and water pump belt to rule out any of that and the knock remained. A stethoscope says it’s from the timing system somewhere.

I’m not very familiar with the vvt system and am wondering if there’s any easy troubleshooting I can do to narrow down what part I need to change? I have a decent scan tool and I’m pretty sure I can actuate stuff with it. I’m pretty mechanically inclined and am not afraid to tear the engine apart.

Anyone here ever deal with this?