- :

- 92 & 16 Meyatas

Looking good!

**********************************

**********************************

Started the truck up for the first time yesterday. It still needs to be tuned but Lui got it to idle. There were a few things to iron out over the last few days but it's all sorted now.

Fuel pump was junk. I diagnosed everything else and had it working at one point but as soon as I upped the fuel pressure it conked out. I picked up an OEM replacement for an '89 Ford F-150 at the parts store that comes with a lifetime warranty.

Alternator wires were reversed so the dash lights weren't coming on. Easy fix.

Throttle position sensor was on backwards. It was symmetrical to mount on either side and the instructions weren't all that clear...but it was another quick fix once we saw the values reversed on the ECU.

Thermostat wasn't opening so I replaced that to be safe.

Well once it's running I plan to just start driving it until next winter. No more projects that will take it off the road. However I do have some things I need to tweak...

The fuel lines and fuel filter under the bed of the truck need to be upgraded. I have a filter, I have lines, I just need various fittings and some help taking the bed off.

I have an extra wire going to the front of the car. Either it's going to power the windshield washer, or serve as a low coolant warning. Can't decide if I want the washer reservoir in the engine bay. The low coolant sensor was never connected so...it's no biggie.

I need to work out an oil catch can of some sort, or hook up a PCV valve to the new intake.

Getting the OMP working again would be nice, but I'll just premix for now.

I want to rebuild the wiper mechanism, it's binding and really slow despite now having a full 14v to operate (old alternator was pretty weak).

The audio system could use some attention. Not a lot of room for kick panel speakers but I've seen others put speakers in the doors. I have the seat thumpers and headrest speakers connected but they are poor quality. You know me, I have standards...and I'll need something that can drown out the new intake sound.

Depending on how much power this makes a future project will be to street port the motor and install a LSD. Then, if it's too much power for the suspension I'll consider putting the coilovers back in so I can maybe autox it a few times.

So anyway, plenty of fun stuff to do...but first is the tune so I can drive it. Lui is coming next week. If it goes well, I'll have it at the Mt Washington meet.

Lmk when you want to lift the bed off and I'll come up

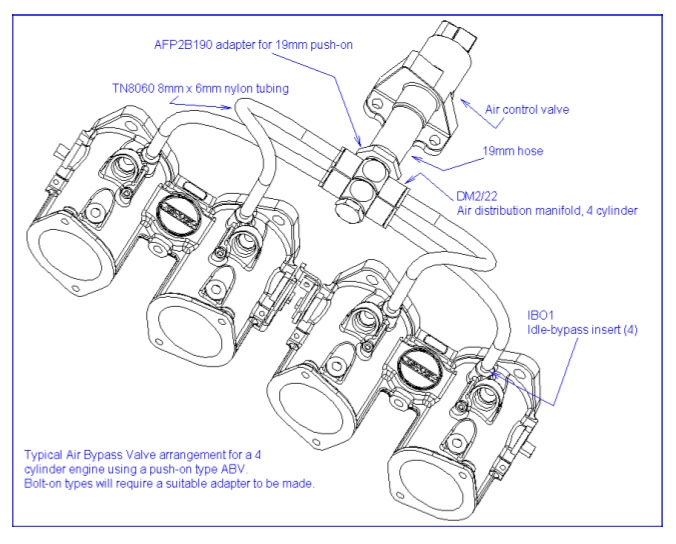

Do you have any pictures of these idle screws? I'm curious since they only method of idle control I have is to crack the butterflies. I'm guessing the screws act like a sort of controlled vacuum leak?There is more room than the photos may lead to. I'll address the vacuum issue below....

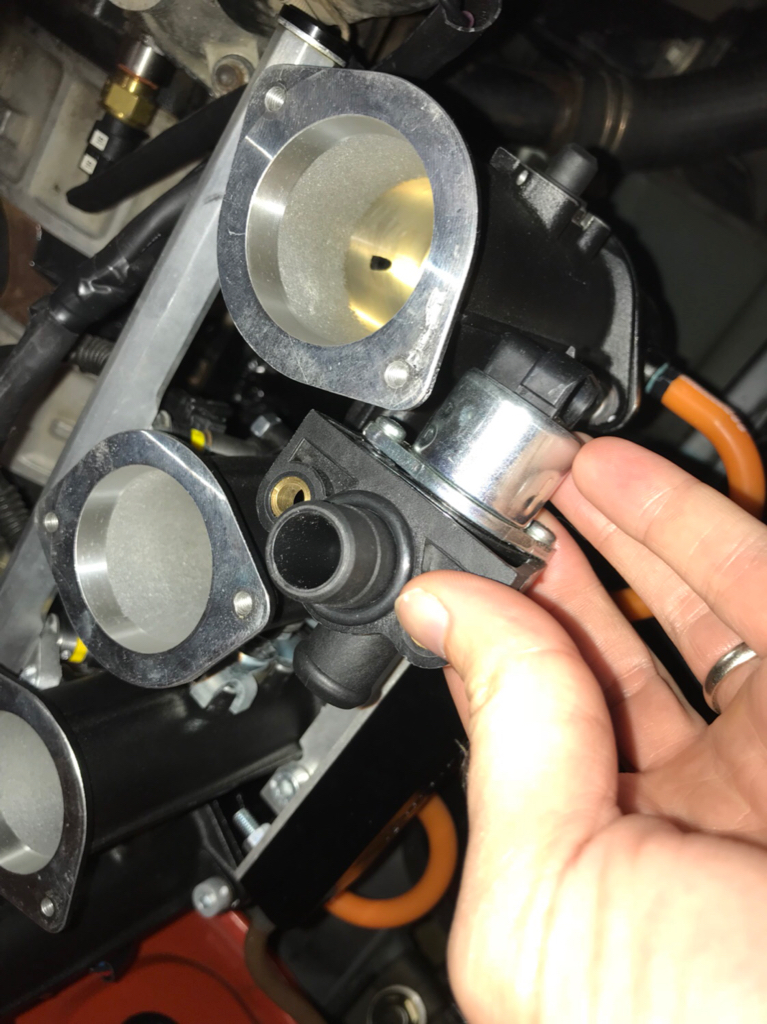

So, the lack of instructions (i.e., no instructions) for the intake, and my relatively beginner status when it comes to these things rears its head again. I took the vacuum barbs that came with the kit and screwed them into the holes they fit into. It turns out those holes are for idle adjustment. Packed away in all the other extra nuts and bolts the kit came with for various throttle linkage options were some idle adjustment needle screws which have the same pitch as the vacuum barbs.

So I took the barbs out, put the idle screws in, messed with adjustments between the screws and cracking the throttle a little and it behaves better now. Ended up with about 2.5 turns of the screws and a slight crack of the throttle. I got it down to an unstable idle at 800Rpm but upped it to 1200 to keep it from stalling.

I was told to avoid MAP tuning and use alpha-n (TPS) only. The internal MAP in my ECU is strictly being used for barometric correction.So that leaves the issue of vacuum. I had side port placed on one of the runners that I was going to use for the brakes (before i found the vacuum manifold) and I grabbed a T to hook both the MAP sensor and brake booster to it. I'm getting a better vacuum signal but since it's only attached to one rotor, the signal isn't reliable. Once I'm driving it's OK, but the ECU is trying to adjust idle and it goes a little bonkers, hence me increasing the idle air for a faster idle. I'm going to tap each of the runners for new vacuum ports but I'm going to proceed with tuning so I can drive it a little. I'm not ready to take the whole thing apart just yet.

Do you have a check valve on the brake booster vacuum signal? I couldn't see anything in the picture that looked like one. I'd definitely tap each runner for a vacuum signal. On my setup both of my runners are tapped and feed into a vacuum block that supplies the brake booster. I also have two other ports for MAP and the fuel pressure regulator should I decide to use them.Oh, I'll also add the brakes feel better. They were originally only getting vacuum from the rear rotor secondary runner so it's no different than stock. I'm hoping to get a little more brake boost when I tap new ports.

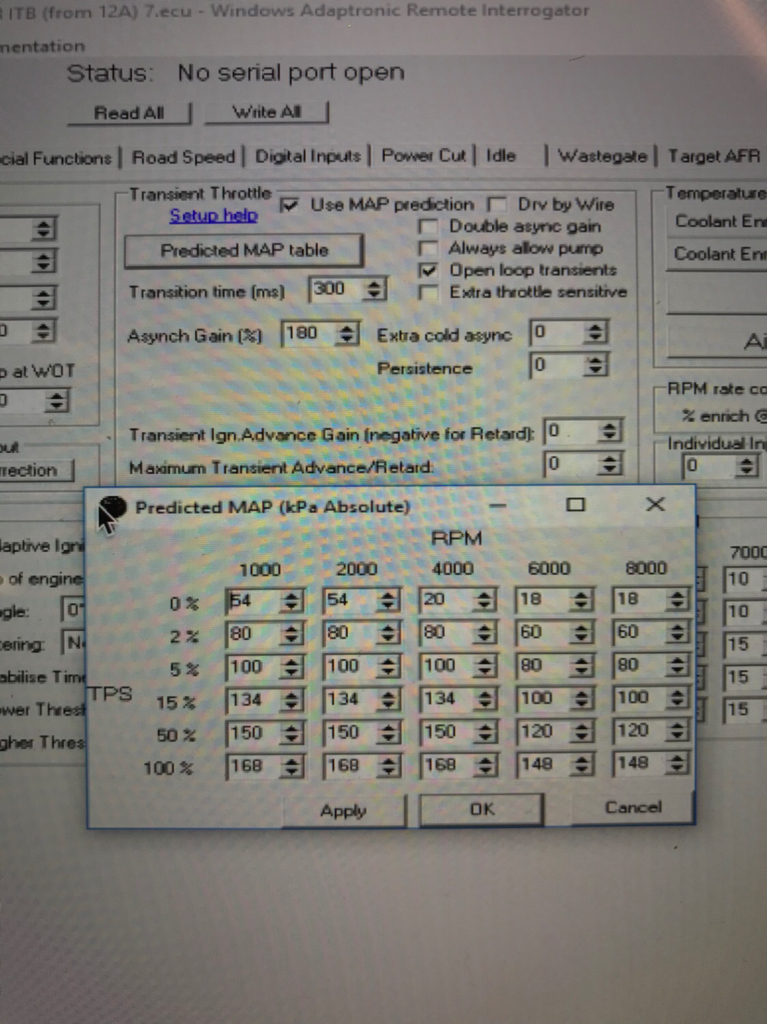

It looks like you're on the right track. Haltech has a "Transient Throttle Enhance" feature that does exactly this. It looks for a certain rate of change in throttle position and adds extra injection cycles to compensate.Back to the driving and tuning. I'm learning more each time I go out. The truck is behaving better at back road cruising speeds. I haven't ventured onto the highway yet. One thing that was bugging me on my drive last night was what I call an "accelerator pump" issue. On a carb, when you punch the throttle, it squirts some extra fuel. The ECU wasn't doing this for me and the truck would go lean when I pushed the throttle down, backfire, the continue on just fine. I read up last night on "transient throttle" and this is a know issue with ITBs because the MAP sensor won't react fast enough. There is a separate table to map predictive MAP sensor values to throttle positions. If the throttle position changes quickly (how quickly and how much is configurable) then the system will ignore the MAP sensor for a short period and read this predictive table instead. That table was way off based on the logging I've been doing so I updated it late last night and I'm going to try it out this evening.