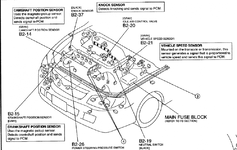

Unless its throwing the code, I'd hold of buying it and use your money elsewhere.I wonder if I should try replacing it <the Knock Sensor> then.

To me it sounds more like a clatter or clattering on acceleration or putting a load like "going up a hill and lugging the engine" or accelerating while braking at the same time to load the engine down.To me, pinging sounds more like a rattle than anything I'd call a "ping." You might be able to reproduce the sound on a normally-working engine by going up a hill and lugging the engine at the same time - or if that's not pinging, it sounds similar to me. Someone here may be able to describe it better.

Here's an article linked below that might help (or not) when I searched for pre-ignition/detonation.

They also talk EGR and Knock Sensor stuff as well.

What Is Pinging, Detonation and Pre-ignition

Me too and noises and vibrations seem to be hard to track down and make go away. You're like me and want a quiet(er) ride but yet want to hear anything unusual going on.My car makes all sorts of noises and vibrations that I don't understand, but I also tend to be a little too concerned and obsessive with small stuff that probably isn't important.

(My wife just turns up her radio louder in her Civic).

I had some front end (rattling) noises while driving that worried me after my clutch replacement that turned out to be coming from the front brake pads as the car didn't have any front brake anti-rattle spring clips and pad holders when I went to replace the brake pads.

I eventually realized the noise was when I was hitting bumps in the road (more pronounced at lower speeds) that I verified went away when I pressed and held the brake pedal slightly before running over them.

After installing the brake clip and retainer hardware, the rattling noises went away.

Some photos attached below:

Other front-end engine/drivetrain vibrations calmed down after I experimented and:

--Installed a hard vinyl shim (about 1/8-3/16" thick) under the front motor mount between the engine support bracket and the mount.

--Installed a (spongy about 3/8" thick) rubber body grommet between the body and rear engine support mount stud and bracket (also added a larger washer under the mounting nut -not shown).

--Installed a piece of rubberized mat about 1/2" thick (probably could used folded rubber hose pieces) between the engine support bracket under the engine/transmission.

--Replaced the Sway Bar Bushings with new Stock OEM rubber bushings and installed a DIY bushing retainer.

Rear end noises were primarily from 155K mile struts, old (and one damaged)s strut links, worn out sway bar bushings, and loose areas of the rear bumper where mount clips were broken (and drilling a few holes and using zip ties did wonders).

The Megan shifter - Well I pretty much RTV gasket sealed everywhere and anything where metal met metal under the shifter body plate, inside the aftermarket metal shift knob void and shifter threads.

--I also broke down and replaced the two bronze shift bushings at the base of the shifter with the OEM plastic ones and packed the inside of all the shift linkage tubes with CRC Silaramic high temp brake grease.

-Now I'm not noticing any vibration (that I can tell) apart from the ringing in my ears from working on F-4/F-15 Fighter aircraft.

Regardless, I'll still probably pull the noisy blower fan motor again to see if I can quiet it up with some lithium or brake grease and vacuum out any cowl debris (again).

Attachments

-

P5 -DIY Rubber Mat Scrap Piece Used for Vibration Dampner Engine Support Bracket .jpg80 KB · Views: 97

P5 -DIY Rubber Mat Scrap Piece Used for Vibration Dampner Engine Support Bracket .jpg80 KB · Views: 97 -

P5 Scrap Vinyl for Between Front Motor Mount and Engine Support Bracket.jpg132.3 KB · Views: 93

P5 Scrap Vinyl for Between Front Motor Mount and Engine Support Bracket.jpg132.3 KB · Views: 93 -

P5 Hard Vinyl Shim Installed Between Front Motor Mount and Engine Support Bracket .jpg72.6 KB · Views: 105

P5 Hard Vinyl Shim Installed Between Front Motor Mount and Engine Support Bracket .jpg72.6 KB · Views: 105 -

P5 Rear Engine Support Bracket DIY Rubber Vibration Dampner Installed.jpg51.7 KB · Views: 103

P5 Rear Engine Support Bracket DIY Rubber Vibration Dampner Installed.jpg51.7 KB · Views: 103 -

P5 DIY Vibration Dampner Between Engine-Trans and Engine Support Bracket.jpg77.7 KB · Views: 92

P5 DIY Vibration Dampner Between Engine-Trans and Engine Support Bracket.jpg77.7 KB · Views: 92 -

CRC Silaramic Brake System Grease.jpg16.1 KB · Views: 95

CRC Silaramic Brake System Grease.jpg16.1 KB · Views: 95 -

P5 Engine Mount Corssmember - Possible Vibration Areas.jpg81 KB · Views: 85

P5 Engine Mount Corssmember - Possible Vibration Areas.jpg81 KB · Views: 85 -

P5 Stabilizer Bar Positioning Bushing.jpg65.3 KB · Views: 95

P5 Stabilizer Bar Positioning Bushing.jpg65.3 KB · Views: 95