Yea not much deals on Fluid Film around here but I find one can do much more surface than a Rust Cure can, might be just the way it sprays in smaller drops.

Is the grease coating similar to Zeibart coating?

I got the car for 650$ so I couldn't complain much about the rust, but I'll do my best to make it look good and rust free on the cheap. If I get the money I'll get a few cans of a mixed paint matching the car (color code 22V). Both drivers doors have been replaced after a small accident and both are not quite the right silver, same thing with the hatch around the badge to cover up the usual rust in that area.

I plan to por15/bondo the passager side which is in much better shape, but the driver side is really junk. I did see the rockauto panel but adding shipping to canada, it's not worth it. I would rather scavenge a panel in better condition at the junkyard and make sure it never rust with por15. There are alternative to welding for this kind of panel :

http://www.shop3m.com/60980030930.html it's kinda hard to find but they claim this is what OEM recommend and will hold better than the metal sheet itself.

Would fiberglass be cheaper? I think the difficulty would be the re-create the shape of the panel as big portion of the lower lip have been ripped of

No I'm not talking about anything like Ziebart or Crown,... I'm talking about crawling under the car with a big tube of grease (I'm thinking maybe looking into something truckers might use on their 5th wheel, really heavy stuff that won't wash off. I'd use anti-seize but that stuff's expensive) and caking the hell out of everything my brush or grimy fingers can reach. I don't know of anyone who's done it, I'm just thinking outside of the box to help arm myself for my battle against rust.

Here's a link to the fiberglass kit at CT:

http://www.canadiantire.ca/AST/brow...24P/Bondo+Resin+Repair+Kit,+1+L.jsp?locale=en

It's got everything you would need for the repair and then some.

You might wanna buy the stuff separately,... I prefer the glass weave over the matt, it's a bit more workable. You'll see the difference when you check out the supplies. Some places sell the weave by the foot but you don't need that much.

You don't make a mold then put it on your car,... you just apply the stuff directly to the car, it bonds very well to metal. (after sanding down to bare metal just like applying ordinary Bondo,... I find a wire wheel on a drill works best. You have to get right into the pits in the metal till everything is completely shiny, even in the depths of the little pit holes. The surface doesn't have to be smooth, in fact the rough pitted surface may cling to the fiberglass better. The bristles of the wire wheel dig in pretty good. You don't want to remove too much metal because it's gonna be your framework for laying the wet fiberglass. That's the hard part.

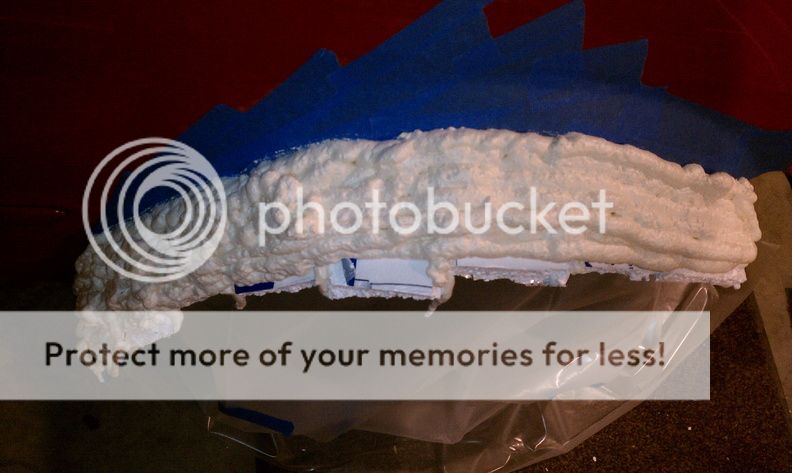

Laying stripps of fiberglass is like trying to lay stripps of bacon on your car. (normal bacon, not the Canadian bacon we're famous for EH!) It's like paper mache, it lays down nice on a horizontal surface with something underneath it (like chicken wire or even paper or cardboard or that yellow/orange spray foam that's hardened then shaped. You would spray that stuff behind the fender to take the shape of the original fender to stick the cloth to then remove it after the fiberglass hardens.) You can't use styrofoam,... liquid resin melts it. Apply some resin to the car with a paintbrush first instead of dipping the strips in the resin. You "paint" the car with resin, then stick the dry strip to it then apply more resin on top then tap it with the end of the bristles. (I cut the bristles in half for that brush. You want to bang the bubbles out of the cloth. It should look clear, any whiteness is a bubble).

This is what Tamn did in his thread (awesome thread,.. I think he's nuts,... I love it):

http://www.mazdas247.com/forum/showthread.php?123812526-Protege5-Smarter-not-Harder!

If you have a full surface area available, you can get the stuff to cling to a vertical surface.

The worse part of working with fiberglass is that it's a freakin mess. It sticks then bonds everything,.. your tools, hands, fingernails,... everything. I've got some tools in my toolbox with fiberglass resin still stuck to them after more than ten years.

It's hard to be neat when you work with it. You apply one strip, then your fingers are sticky and you go to pick up the next piece and you grab the edge and a couple of strands pull off the strip (that's another reason why I prefer the weave over the matt,.. it doesn't come apart as bad) then you use your other hand to pull the string off then it's stuck to both hands the original strip joins the party and if it gets away from you your hands are welded together. (like in American Pie, only hopefully it's just your hands that are involved.)

So with all that to consider (bearing in mind that I go at everything like I'm tarring a roof,... I have have a hard time being delicate) I have found that the best way to clean up is to go to Dollarama and get one of those exfoliating gloves in the girly section for a buck (I got a blue one so it doesn't look so bad).

Those things kick ass getting any kind off crap off your hands,... fiberglass, grease, paint, stain, glue, anything stuck on your hands that needs to be scrubbed off. It works best in the shower after your pores have opened up and the stuff is softer.

Another trick is to rub your hands with vaseline first then wipe off the excess before attacking the resin. (not too much, you don't want it getting in your resin.)

Good luck getting it off your fingernails,.. it might have to grow out.