You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The massive Boost Thread

- Thread starter TurfBurn

- Start date

http://importperformanceparts.net/

you have to navigate to the bearings

*edit* there they are:http://importperformanceparts.net/toga/togabearings_mazda.html

you have to navigate to the bearings

*edit* there they are:http://importperformanceparts.net/toga/togabearings_mazda.html

Your working with mirotech? i was just getting ready to start something with thier ecus. im just breaking into the details with it, theres been talk of harnesses and things. Hopefully getting my motor and everything off the ground in april-june... Id like to talk to you about it.TurfBurn said:The microtech systems we are trying to bring in as well can do external Bosch coil packs. As that will be an additional option available.

subbing to this as well.

Where the standard size a tight enough clearance? I'm going to have to take measurements because I had an align hone done on my mains... and I want to try to tighten the clearance down to about 20 thousanths on the bearings for better lubrication. I was told that 30 was pretty much way too much even though that is essentially the stock clearance.RyanJayG said:http://importperformanceparts.net/

you have to navigate to the bearings

*edit* there they are:http://importperformanceparts.net/toga/togabearings_mazda.html

- :

- Das Pretzelwagon

Subscribes.

Let it be written down that you are all insane

<--- doesn't plan on running more than 9psi

Let it be written down that you are all insane

<--- doesn't plan on running more than 9psi

But wait till the darkside puts its fangs into you and you feel the unharnessed power waiting to be unleashed with more boost!Pretzellogic said:Subscribes.

Let it be written down that you are all insane

<--- doesn't plan on running more than 9psi

TurfBurn said:But wait till the darkside puts its fangs into you and you feel the unharnessed power waiting to be unleashed with more boost!

So that's what it was??

so which model did you choose? these ones? I am going to order mine as well now that I ordered my ARP studs, JE pistons and Oliver rods

<table border="1" bordercolor="#c0c0c0" cellpadding="2" cellspacing="0" width="100%"> <tbody><tr><td align="left" valign="top">azda 626 MX6</td> <td align="left" valign="top">FS</td> <td align="left" valign="top">93-00</td> <td align="left" valign="top">16 valve DOHC 4cyl.</td> <td align="left" valign="top">MBMA17-HP

$69</td> <td align="left" valign="top">RBMA17-HP

$69</td> <td align="left" valign="top">$125

Save $13</td></tr></tbody> </table>

<table border="1" bordercolor="#c0c0c0" cellpadding="2" cellspacing="0" width="100%"> <tbody><tr><td align="left" valign="top">azda 626 MX6</td> <td align="left" valign="top">FS</td> <td align="left" valign="top">93-00</td> <td align="left" valign="top">16 valve DOHC 4cyl.</td> <td align="left" valign="top">MBMA17-HP

$69</td> <td align="left" valign="top">RBMA17-HP

$69</td> <td align="left" valign="top">$125

Save $13</td></tr></tbody> </table>

One of those models is the mains, and the other is the rods... MB - Main Bearing, RB rod bearing... But the FS set you are indicating I believe is correct.

You should do both sets. Also, you need to know if you need the STD, +10 or +20's depending on what machine work is being done or not done.

I believe if you have no machining done you can just use the STD. HOWEVER, that isn't a guarantee as there is variation from the factory and due to wear etc... so make sure either you or your builder know what is up on those... I'm still working on getting a 100% understanding of it. I need to measure my rods and my crank journals and also my mains to verify waht sizing I need since I had my main saddles align honed for better performance and accuracy.

Later.

Steve

You should do both sets. Also, you need to know if you need the STD, +10 or +20's depending on what machine work is being done or not done.

I believe if you have no machining done you can just use the STD. HOWEVER, that isn't a guarantee as there is variation from the factory and due to wear etc... so make sure either you or your builder know what is up on those... I'm still working on getting a 100% understanding of it. I need to measure my rods and my crank journals and also my mains to verify waht sizing I need since I had my main saddles align honed for better performance and accuracy.

Later.

Steve

block splitting inhalf

I will try to find the post, but i seen this on honda tech where there is a guy running in the NDRA circuit and he is running up in the 26psi to 28psi range, and the block is splitting about 3" below the head completly all the way around and he has done it twice so that might be another problem to look out for

I will try to find the post, but i seen this on honda tech where there is a guy running in the NDRA circuit and he is running up in the 26psi to 28psi range, and the block is splitting about 3" below the head completly all the way around and he has done it twice so that might be another problem to look out for

- :

- 2001 Pro 2.0 LX

subscribing....I remember seeing that block splitting but if I recall it was from a V-6 or V-8 not I-4 or I-6

So back to this welding in a nickel rod to help stop crank walk... It obviously can't be between the mains themselves as the crank is passing through there. So are you welding on the upper oil pan somehow between the bolt points? Are you going in the direction of the crank (cylinder array oriented) or are you going perpendicular/with the journal (which would do little for lateral improvements). This seems like it would be a reasonable affordable and simple thing to do, just a matter of knowing what to do. I'll definitely throw it on my "list" of things to do during the build of the block.

Yeah we are all a bit crazy... it's the boost...

It'll be humorous though to be able to light up the tires in 3rd gear at 60 if ya want LOL... traction will become the issue... but I want to overbuild the motor, and then run less than my "intended" design. But at the same time my idea of reliability is "only" having to replace the block and redo the rings and bearings every 30 to 40,000 miles

LOL... traction will become the issue... but I want to overbuild the motor, and then run less than my "intended" design. But at the same time my idea of reliability is "only" having to replace the block and redo the rings and bearings every 30 to 40,000 miles  LOL. (about every other year in theory).

LOL. (about every other year in theory).

Yeah we are all a bit crazy... it's the boost...

It'll be humorous though to be able to light up the tires in 3rd gear at 60 if ya want

Last edited:

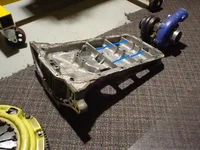

actually that part is aluminum, so its not the part we're talking about. .. its kinda hard to describe, but if someone has a picture of an FS flipped upside down with no crank in I could point it out. its actually above the crank, I'll just have to show you.

Hence my confusion as to how this was being doneRyanJayG said:actually that part is aluminum, so its not the part we're talking about. .. its kinda hard to describe, but if someone has a picture of an FS flipped upside down with no crank in I could point it out. its actually above the crank, I'll just have to show you.

Later.

Steve

EDIT: Picture attached now.

Attachments

Last edited:

ok, red arrow indicates how the crank walk is probably occuring. the yellow box is one area to weld up, making thicker to combat this (for all 3 ribs), and the blue arrow points to up under the ribs to a large area that can be welded onto to make thicker, or even gusseted.

I believe if you can strengthen the ribs you can combat the crank moving laterally due to flexing of the block

New Posts and Comments

- Article

- Replies

- 0

- Views

- 44

- Replies

- 9

- Views

- 286

- Replies

- 1

- Views

- 750

- Replies

- 3

- Views

- 159