It's no secret that

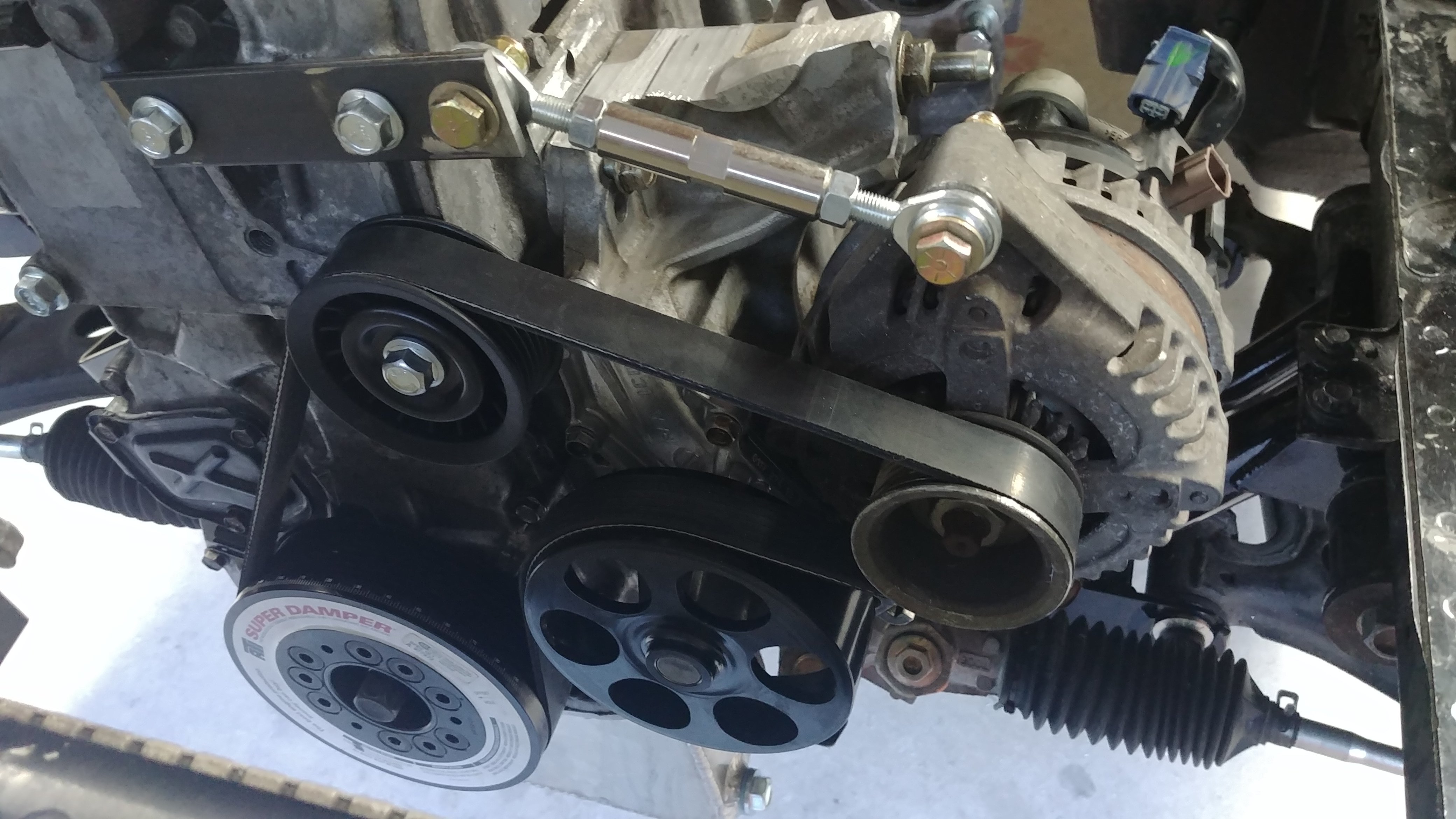

I don't like the way they tension the accessory belt in this swap. I absolutely believe them when they say it works and is reliable on their & their customer race cars, but I picture myself in a wet, gravel or sand paddock space at a track or on the side of a mountain, needing to replace an alternator or water pump, and losing half of those damn washers in the dirt.

Given that, I had grand plans of turning up a couple sets of custom length spacers (one to have as a spare) on the lathe, until a different option was presented.

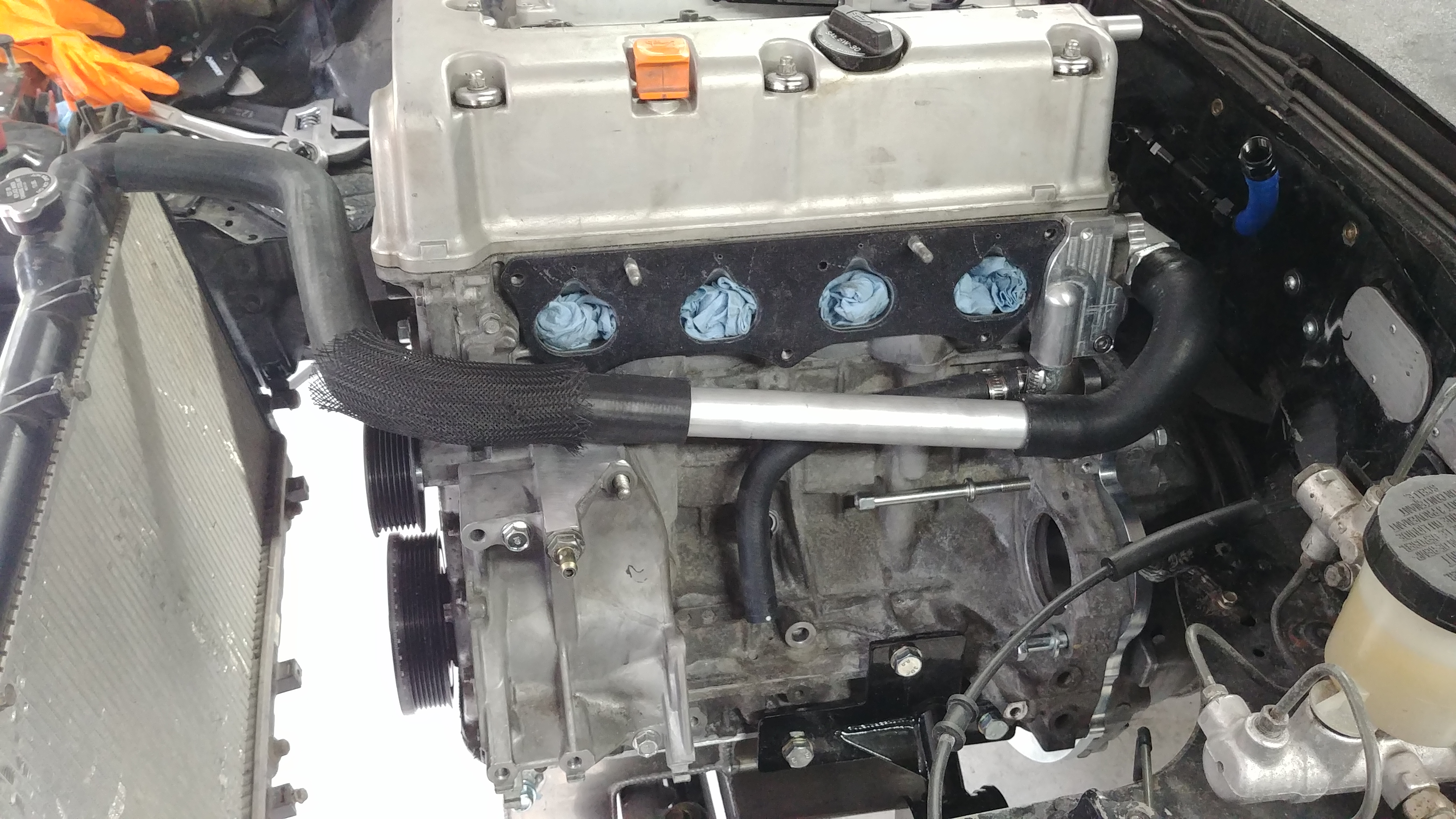

The alternator on the 08+ Accords and 09+ TSXs (from a K24z3, vs the K24a2 that I have) has a single-bolt bottom mount that runs parallel to the engine. IE: It can swivel. IE: If I can figure out a way to make that work, I can use a simple turnbuckle style tensioner and never worry about losing a boatload of small parts just to change a belt.

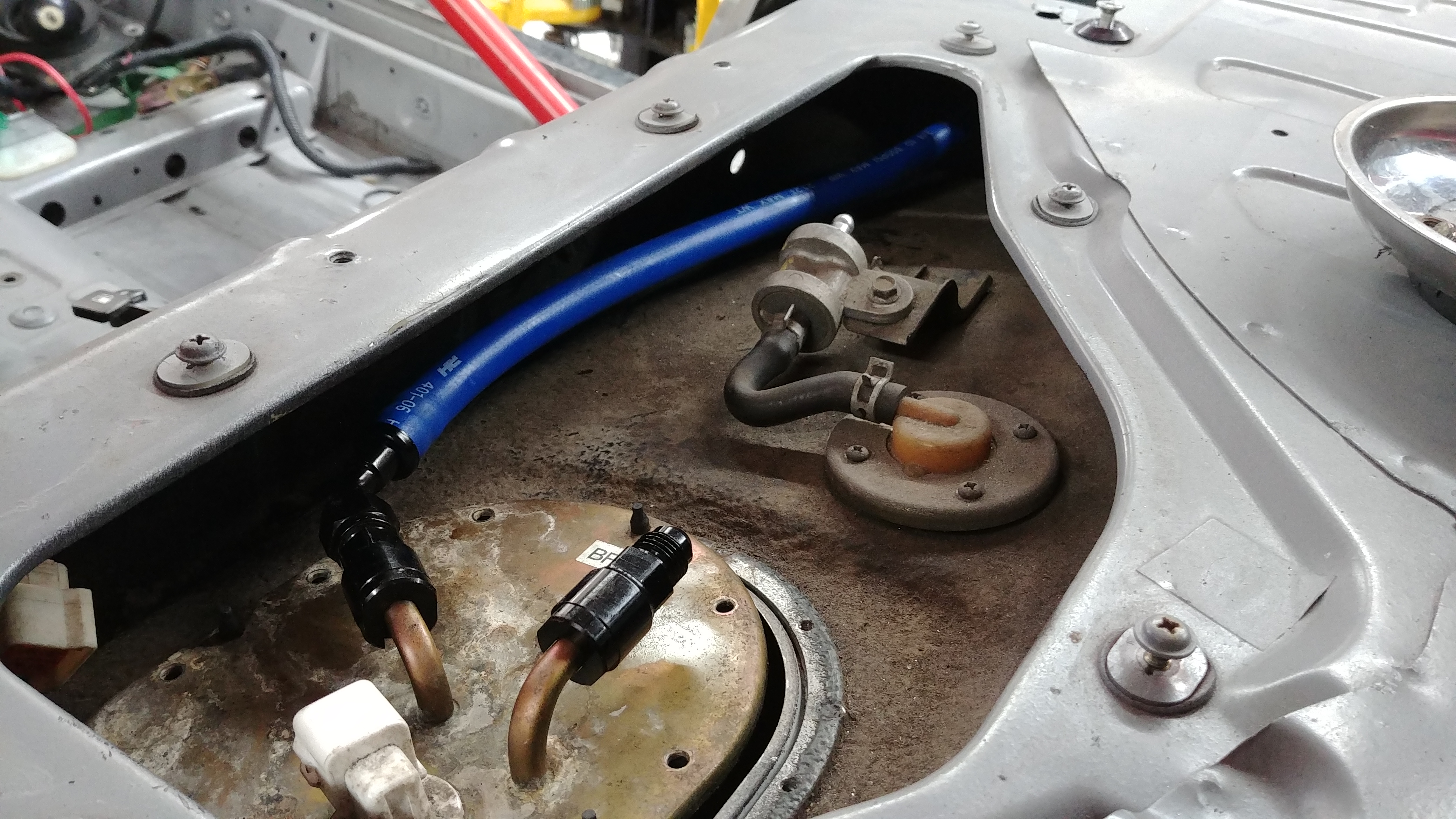

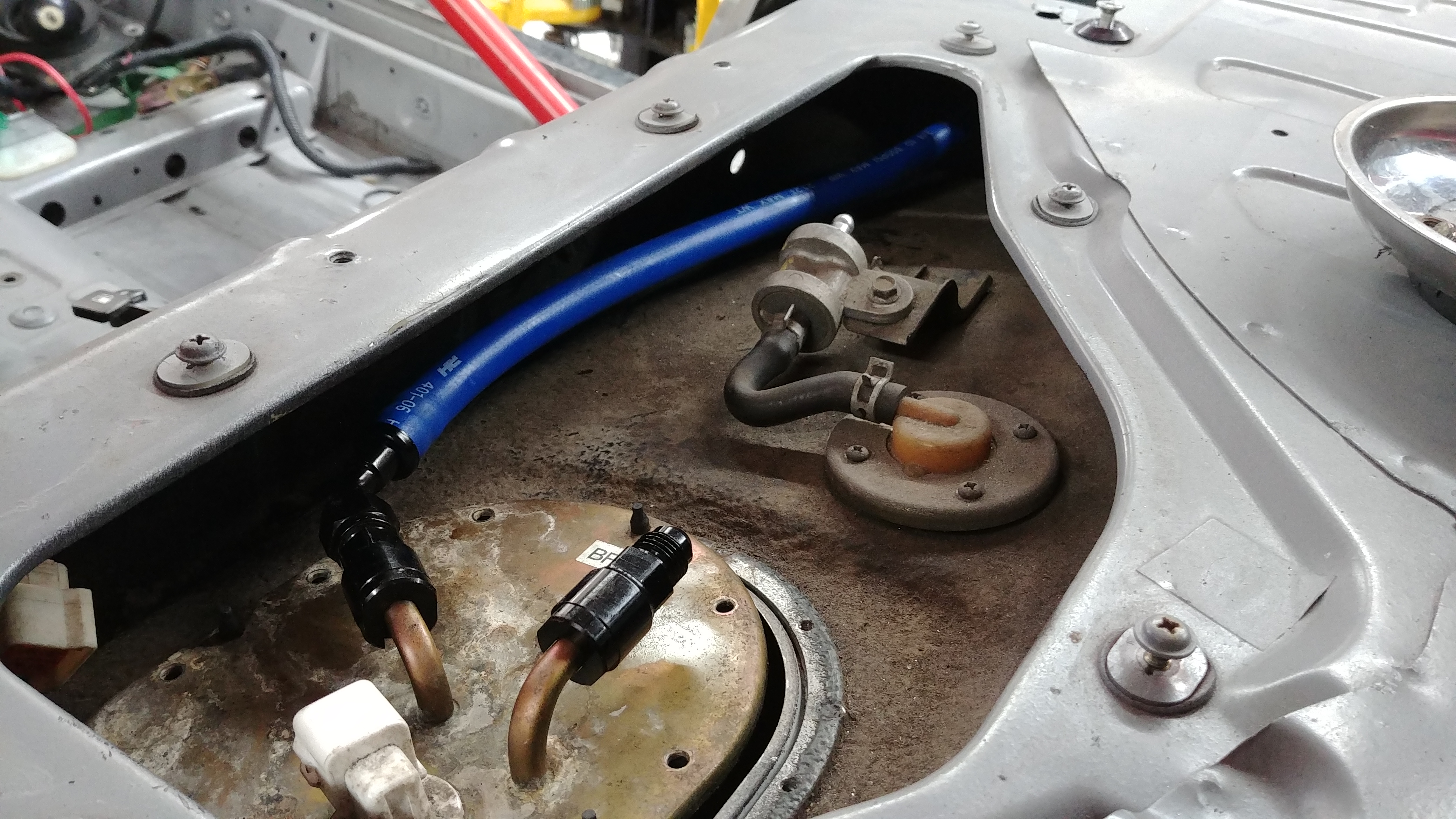

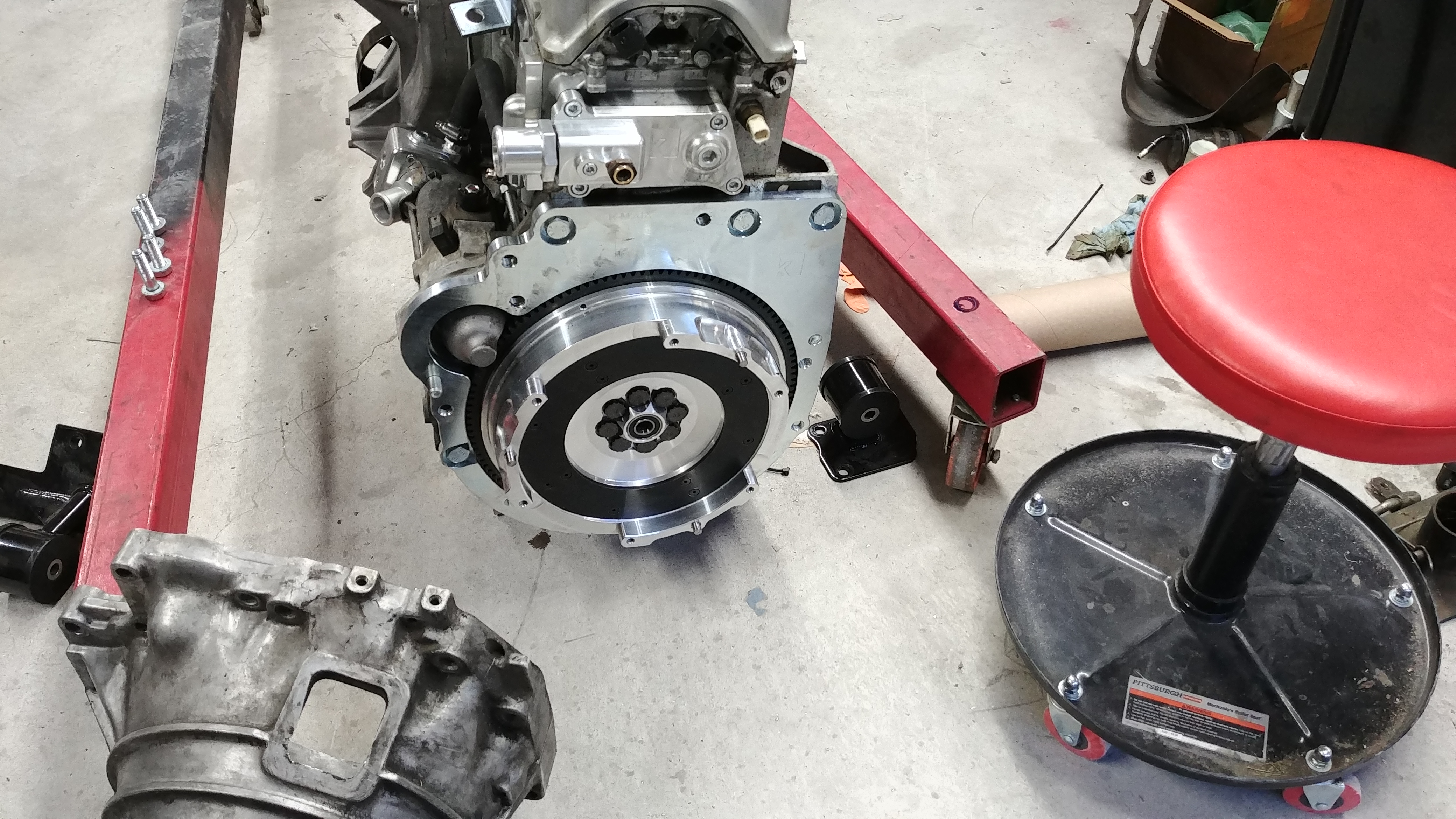

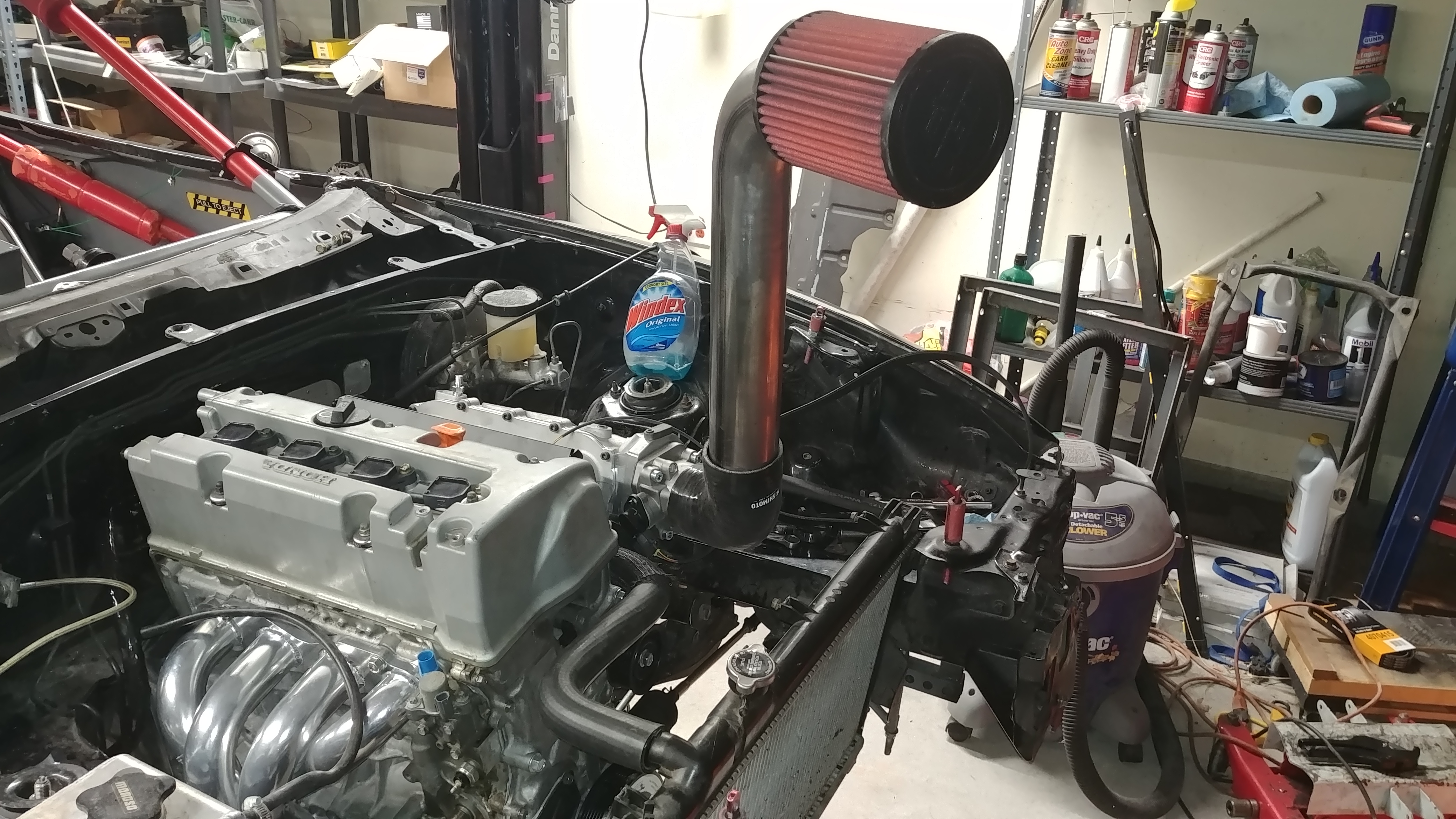

The alternator mounts on the side of the "water housing". A weird aluminum casting that bolts to the driver's side (in this RWD configuration) of the engine that the water pump bolts to in the front, the thermostat housing bolts to in the rear, the alternator on the side, and the big stock tensioner bracket (that I cut off to route the coolant hose) on top. It *appears* that I can simply swap to a later water pump housing

Off to EBay to load the parts cannon!

I got the z3 water housing in and things looked ok to start with, but I found 2 problems.

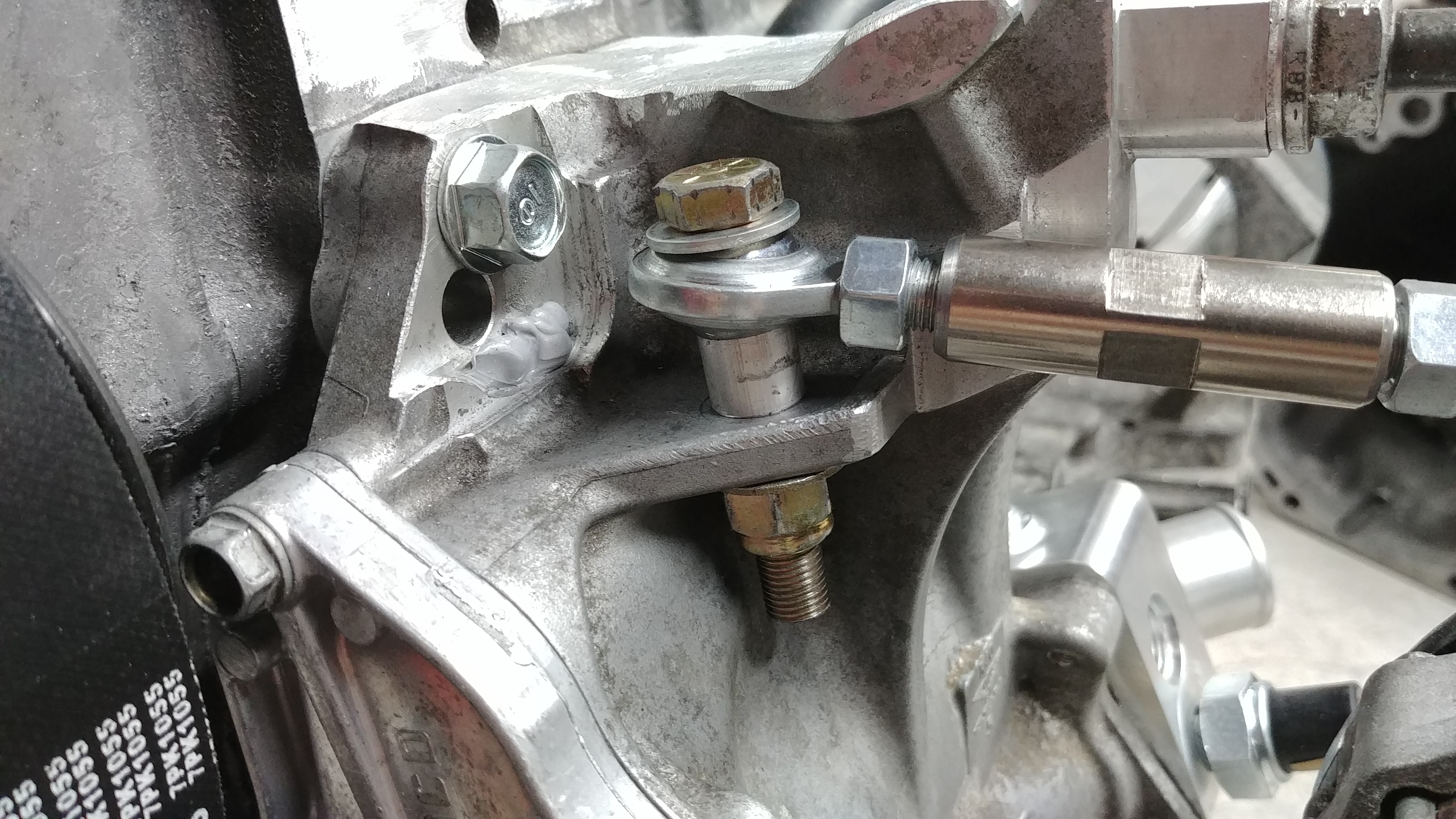

1. the bolt bores are different sizes / lengths. The z3 housing uses 2 long studs (vs 1 long and 2 short), and then 1 long bolt and 1 short (vs 2 long). That's fairly minor, I just need to grab a stud and bolt. I could honestly get by with 3 bolts, but the studs help when sliding it on the first time when it's covered in RTV so I don't screw that up horribly.

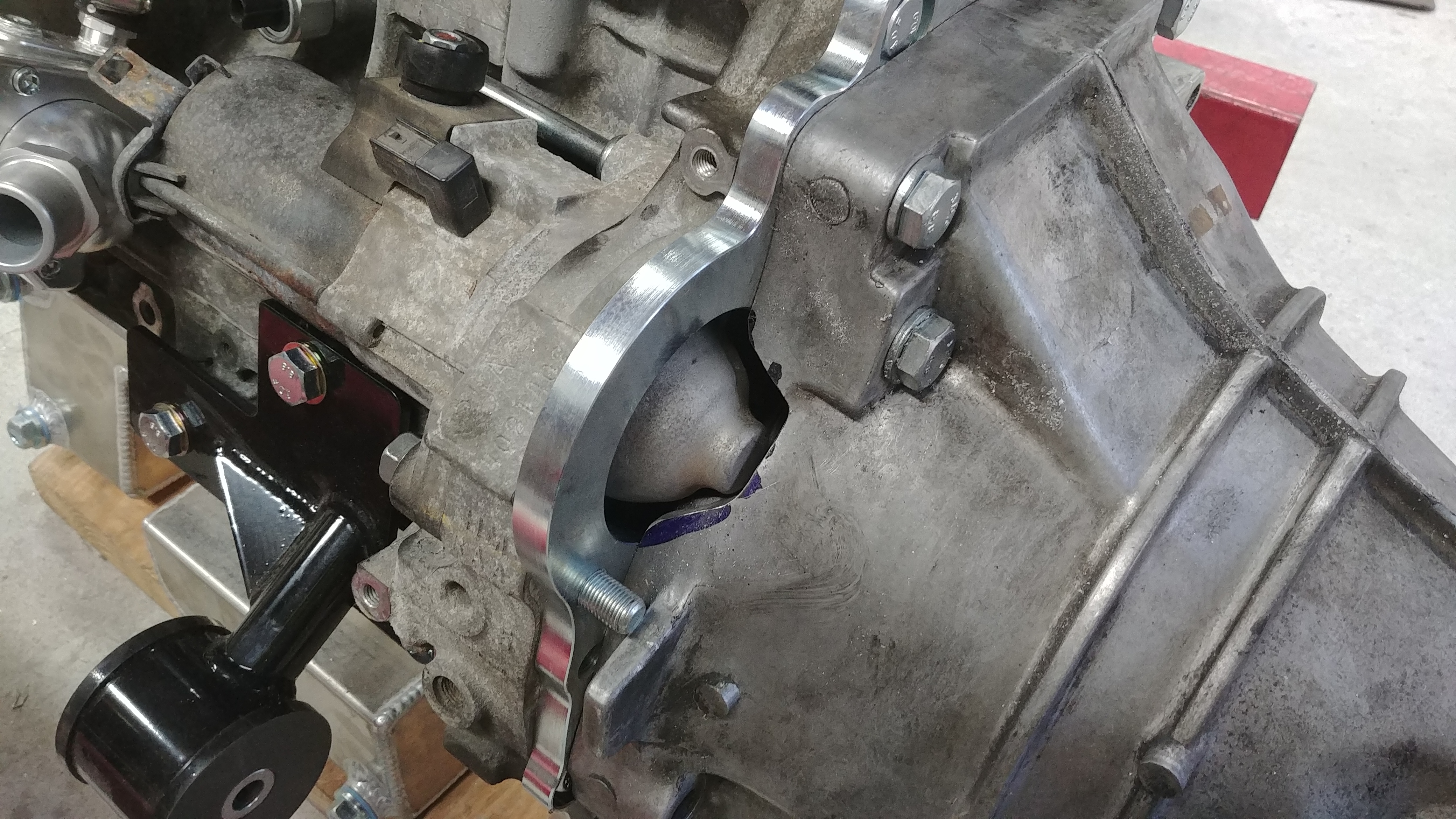

2. This one's bigger, and will require a little help from my friends. The K24z3 housing is on the left, the K24a2 housing is on the right.

The z3 housing uses 3 of the 4 bolt holes the same as the a2, but the one at the upper right (sharpie pointer) is in a different location.

HOWEVER: The hole from the original a2 pattern is *nearly* drilled through in the z3 housing so I've got something to work off of.

I didn't want to have my machinist go through all the trouble of milling this thing down if the hole pattern wouldn't line up, so I used a slightly undersized drill-bit to knock the bottom of that bore out. This way, the original bore is still there to locate an endmill off of to bore it correctly.

That top bolt is actually tight but it's sitting on that step in the casting on the back side of the bolt. We (and by we I mean Dave) will mill in a flat for the bolt to sit flat against.

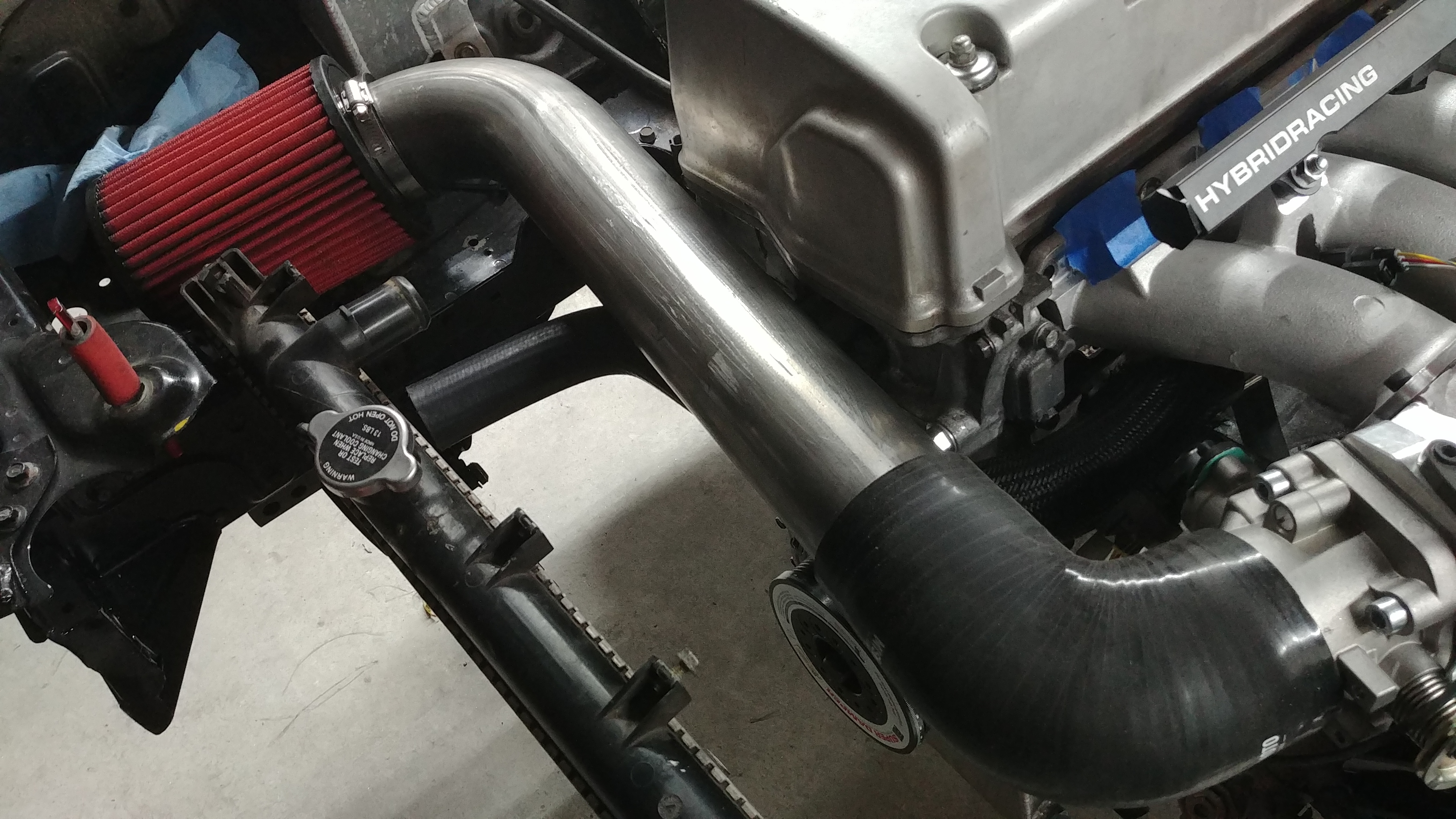

The alternator and a turnbuckle that looked to be about the right length are coming in on Thursday, then I can play around with where I want to actually mount the thing. I might use 1 of those bosses at the top, I might pick up on 1 of the water housing bolts. We'll see.