haha, good luck dude.twilightprotege said:got a suggestion for those who are brave enough.

where the vics chamber is, use metal epoxy to block each runner off. then drill through the bottom of each new vics tube straight to the plenum. and there you have it. a true dual runner IM.

so who's game?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Intake Manifold Modifications.....

- Thread starter BlkZoomZoom

- Start date

twilightprotege

Member

- :

- 2001 323 Astina SP20 (P5)

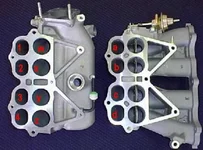

see attached picture.

this is the 2 halves of the manifold.

left is the bottom half, right is the top half.

anyway, on the bottom half, w x y and z are the vics runners. they just link to a chamber. they are all linked together - ie so air can move from w to z etc.

anyway, eith metal epoxy filler, make those holes in to runners. then drill through the bottom of the new runner and you should be pretty much right at the plenum.

so when the VICS opens the butterflys you have a dual runner IM

but what i would suggest first is to make the opening into the plenum small. that way you can keep going slightly bigger in search for more power. much easier than having to make the hole smaller in search for more power.

i was going to do this ages ago, however i just dont have time and with only 1 car it makes it a little difficult. but i would still like to try this one day. i'm sure it would work. you just need to get the holes to the plenum correct and it'll make a crap load of power when the VICS opens!

this is the 2 halves of the manifold.

left is the bottom half, right is the top half.

anyway, on the bottom half, w x y and z are the vics runners. they just link to a chamber. they are all linked together - ie so air can move from w to z etc.

anyway, eith metal epoxy filler, make those holes in to runners. then drill through the bottom of the new runner and you should be pretty much right at the plenum.

so when the VICS opens the butterflys you have a dual runner IM

but what i would suggest first is to make the opening into the plenum small. that way you can keep going slightly bigger in search for more power. much easier than having to make the hole smaller in search for more power.

i was going to do this ages ago, however i just dont have time and with only 1 car it makes it a little difficult. but i would still like to try this one day. i'm sure it would work. you just need to get the holes to the plenum correct and it'll make a crap load of power when the VICS opens!

Attachments

twilightprotege

Member

- :

- 2001 323 Astina SP20 (P5)

dont forget dual runner designs have the best of both worlds. low end and high end power

DSMConvert

AWD...say Bye Bye

- :

- Titanium MS6

hey flat yea just let me know, #6 pipes are almost done they're mandrel bent just hafta finish laser cutting the ss flanges.....lower comp pistons are a good thing when building an engine, allow for more boost, b/c the boost benefit you would gain is greater than the performance you'd loose from lowering compression.for example you might lose 10% from lower compression, but you'd gain 25% from higher boost levels....ok no more thread jacking...

I plan on using a GT30 turbo. Lower compression pistons will allow me to raise the boos significantly, hopefully to the tune of 25-27 lbs.TurfBurn said:Not to completely threadjack but I wanted to hear your thoughts, Foucs, on why you decided to go with 8.5:1 pistons instead of 9:1's. I haven't done my pistons yet and I'm still hmming and haaing a bit about it... leaning toward the 9's though still at this point.

So you are saying to plug the 4 vics holes, and then drill them to connect to the other 4? or somehow to the lower chamber?twilightprotege said:anyway, eith metal epoxy filler, make those holes in to runners. then drill through the bottom of the new runner and you should be pretty much right at the plenum.

Would this be worthwhile for me since I don't even have a VICS system?

Not plug the VICS holes, but add a wall to separate them into runners. Twilight and I have discussed this some. From the factory the VICS butterflies control holes opening into an open chamber. He's saying separate them into runners and drill them through into the plenum. When the butterflies open, voila! short runners.

flat_black

Member

Man, filling that sucker with epoxy would make the manifold heavy as hell. =)

On Twilght's pic w,x,y, and z are openings into a chamber, once beyond the initial wall between those holes there is no separation between them. He is saying to build a wall to continue the separation. And keep in mind the VICS chamber is not connected to the plenum.

flat_black

Member

Yeah, I see what he means, but still... If you were to fill it with epoxy and drill through, that would be one heavy-assed setup, even if it were just the VICS chamber. Maybe I'll try this at some point, but I'll probably bore the openings out and put piping down into the plenum instead, if I can figure out a good way to do it.

flat_black

Member

If you could get into the plenum, you could actually push the tubes up through, with flared velocity stack ends, to smooth out the flow... Unfortunatly, that would require you to cut the plenum in half, then welded back together. Which would be a reeeeaaaal pain in the ass.

As far as the epoxy goes, there'd be so much that it wouldn't have a chance to flake. Hehee. But it doesn't seem like a proper solution to me, anyway, either. =)

As far as the epoxy goes, there'd be so much that it wouldn't have a chance to flake. Hehee. But it doesn't seem like a proper solution to me, anyway, either. =)

twilightprotege

Member

- :

- 2001 323 Astina SP20 (P5)

yep you guys understand what i was talking about now.

the other thought i had was similar to what flat_black just said. dont fill anything with metal or epoxy, just drill through into the plenum and then make sleaves out of some sort of metal etc tube and they'll become the runners

and when i was saying to add epoxy to the VICS chamber, i was meaning just to block the flow between w x y and z. doesnt need to be a complete fill

and turf, you do have VICS, you dont have VCTS (the tumble system)

but guys, just like what wrench said, it's a lot of work, but the potential pay off could be huge!

the other thought i had was similar to what flat_black just said. dont fill anything with metal or epoxy, just drill through into the plenum and then make sleaves out of some sort of metal etc tube and they'll become the runners

and when i was saying to add epoxy to the VICS chamber, i was meaning just to block the flow between w x y and z. doesnt need to be a complete fill

and turf, you do have VICS, you dont have VCTS (the tumble system)

but guys, just like what wrench said, it's a lot of work, but the potential pay off could be huge!

DSMConvert

AWD...say Bye Bye

- :

- Titanium MS6

man whenever you start talking about doing severe modifications like that its just best to have a custom intake manny made...now yes i'm spoiled b/c dsm parts were very very easy to come by and anything you could think of was probably already made, but still....changing air pathways and such is a very dangerous game to play if you dont know the effects it might have...air velocity has a lot to do with engine performance and the engine will not respond well when its slowed down or speeded up beyond certain air limits of the flow design....

New Posts and Comments

- Replies

- 3

- Views

- 174

- Replies

- 16

- Views

- 258