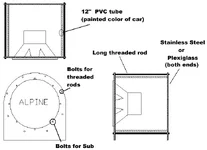

Attached is a picture I drew up of a custom sub enclosure. It consists of PVC pipe, with stainless steel plates on either end. Teh sub would mount to one of these plates. There is an o-ring (or other method of seal) between the plates and PVC. The plates are held to the PVC (and o-ring) by "pinching" them together with steel rods (bolted evenly on each end). The picture should show this well. I am going to do a 3-D drawing as well in IDEAS. The PVC would be painted the color of my car. The stainless steel plate behind the sub could actually be plexiglass so you can see the magnet. These plates would be laser-cut. This could bolt to the floor, or upside-down where the current system is. I could also fiberglass this PVC to "mold" it to the truck ceiling, and have it kinda hang. This was an old idea of mine, that would make a sealed box very well. Terminals would be mounted on the plate or PVC somwhere. The internal volume would be easy to find (pi*r^2*h). Where h is the length of the PVC and r is the PVC's ID/2. Let me know what you think. Cutting the PVC perfectly straight would be key, and making an o-ring groove in the PVC would be time-consuming.....but nonetheless...it can be done. Custom amp rack would be made as well.

I figured I could position the sub enclosure in different directions, to see what sounds best....then determine how I wish to mount it. Does the system sound better if the sub is facing the inside of the car, or the back of the trunk in the MSP? My old systems sounded better facing back, as the sound reverberated off the trunk lid and back into the car.

Thanks for reading....your opinions would be greatly appreciated.

Oh yea....it will be an Alpine 10". Either type S or Type R. Probably R with mono amp.

I figured I could position the sub enclosure in different directions, to see what sounds best....then determine how I wish to mount it. Does the system sound better if the sub is facing the inside of the car, or the back of the trunk in the MSP? My old systems sounded better facing back, as the sound reverberated off the trunk lid and back into the car.

Thanks for reading....your opinions would be greatly appreciated.

Oh yea....it will be an Alpine 10". Either type S or Type R. Probably R with mono amp.