Good point mid_life_crisis......yeah im running 1 step colder plugs..and right now got about 100 miles or so on the stage 1sf map..going so good so far..ive been driving like a granny so far..but think tonight I can do couple hard pulls and datalog and see where it goes. Long as ican run fairly safe till i get my dp and custom tune ill be happy

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cobb AP datalog Pull

- Thread starter zx2man

- Start date

Not gonna do a dyno pull until I'm pretty happy with the tune. And as of now, we've still got a couple of issues to finesse until I can call the tune complete. Although getting more power is the point of all this, I'm more concerned with getting a good, safe tune for the time being as this is my DD. The push for more power will come later.

thats cool, just interested in what kinda numbers you made with the map

thats cool, just interested in what kinda numbers you made with the map

Yah, for those that are fiddling with RaceTuner, I'm sure we're all a bit anxious to see what we can squeeze out with just bolt-ons. I know I am so I'll definitely post up my findings when I finally get to a dyno.

Bravnik is saying that with the duty cycle at zero you are making more boost than with it higher, because the wastegate is closed, not bleeding off boost.

That is a misunderstanding.

With the duty cycle at zero, boost pressure will be minimized.

If you disconnect the wastegate solenoid valve (the equivalent of 0% duty cycle), the boost pressure would be limited to ~10 PSI (assuming no mods).

Matsuda is pointing out that the high duty cycle shows that boost is high because the ECU is trying to bleed it off by opening the wastegate.

That is also a misunderstanding.

The high duty cycle (the OP's log has a max. of >99%) shows that the ECU has "cranked up the boost to the max" by closing the wastegate as much as it can (it cannot close the wastegate completely). It makes perfect sense considering 17.5 PSI @ ~6000 RPM with a small turbo.

Stop the pissing match before it starts and derails the thread, okay?

Bravnik made the incorrect assumption that "Wastegate duty %" was referring to the actual wastegate opening. Should I have not said anything?

Understandable..and as soon as I get a dp and custom tune i will post dyno slips..these things take time for me..due to budget and whatnot..I seem to add on to the car as ican afford to do so...ive had the car for 5 months now and got my current mods..not too bad..it will be few more before i got the custom tune..but yeah its awesome to know what these cars are capable..and if i get bored in the next few weeks maybe ill get the car dynoed on the stage 1sf map im running now..cause im kinda carious as well...on side not..i did do a strong 1-3rd gear pull today..and the highest knock I got was 0.7...so thats alot better than the 4.5-4.9 knock i was getting on the stage 2 map...so ill let it break in alittle more and then do some good 4th gear pulls and see what happens..I think this stage 1sf map is gonna work alot better for me,but time will tell

I think this stage 1sf map is gonna work alot better for me,but time will tell

Considering your mods, I think the Stage1+SF map is the best fit. I didn't like the Stage2 maps at all (other than the more linear throttle response) when I tried them out a while ago. If you have access to 93-octane, I suggest you try the Stage1+SF 93 map. I've had the most success so far tuning off this map although going by the log you posted, it seems like the Stage2 map you tried wasn't exactly hurting you in terms of power.

Denso itv22s in his signature say hes running 1 step colder plugs.

I was getting crazy knock (5-6) with the AP and it turned out to be the densos.

My bad I didnt see it.

Was the knock because of the densos ? My densos just came in yesterday, and I'm still waiting on my AP.

That is a misunderstanding.

With the duty cycle at zero, boost pressure will be minimized.

If you disconnect the wastegate solenoid valve (the equivalent of 0% duty cycle), the boost pressure would be limited to ~10 PSI (assuming no mods).

That is also a misunderstanding.

The high duty cycle (the OP's log has a max. of >99%) shows that the ECU has "cranked up the boost to the max" by closing the wastegate as much as it can (it cannot close the wastegate completely). It makes perfect sense considering 17.5 PSI @ ~6000 RPM with a small turbo.

Bravnik made the incorrect assumption that "Wastegate duty %" was referring to the actual wastegate opening. Should I have not said anything?

Ok, I'm not sure what crack you are smoking, but that is not how a WG works bro. Here is the definition of a WG and what it does.

"The wastegate (WG) is part of a feedback loop used to limit boost. The boost controller, be it manual or electronic, the turbo, and the wastegate make up the elements of the loop. As boost builds, the controller monitors the pressure. When the pressure exceeds the controller's set point, it supplies air pressure to the WG actuator (the thing that moves the WG). The WG opens and diverts some of the exhaust flow away from the turbo. The turbo slows a little and the boost drops to below the controller's set point. When this happens, the controller stops supplying air to the actuator and the WG closes. The cycle repeats over and over until you stop nailing the accelerator!

How much the boost varies about the set point is a function of the "gain" of the loop and how much it is "dampened." It's more than you probably want to know.

There is a spring in the WG actuator that has a lot to do with how well the WG remains closed while boost builds. The WG actuator has to overcome the spring force to open the WG. The exhaust gas pressure isn't very significant so the actuator has to do most of the work. The spring force has an affect on the "gain" of the loop, so it can affect the loop response time.

Small turbos imply low boost levels so they are able to employ internal WGs. A small turbo running high boost levels (not recommended since turbo efficiency falls off dramatically) can overwhelm its WG and boost creep will result (the gate can't open enough to divert the huge amounts of exhaust gasses away from the turbo). External WGs are often larger and can more effectively divert larger amounts of exhaust gasses away from the turbo when they open.

Boost creep is what happens when the boost climbs beyond the set point limit established by the controller. Boost creep is caused by the inability of the WG to divert enough exhaust gas away from the turbo. There are several reasons this can happen but the cheap solution is to lower the set point!

WG designers expected a significant pressure difference on either side of the WG valve. It is required so the gasses rush through the valve when it opens. If the pressures on both sides of the WG are equal, nothing happens when the WG opens (so no boost regulation can happen). What can make the pressures equal? A restrictive exhaust system!"

Unless I'm TOTALLY misunderstanding your point, you need to do a bit of reading before you come into a forum and tell people they are wrong friend.

So again 0% is a CLOSED WG = Boost can build as it is not being bled off. 99% WG is a completely open WG allowing exhaust gases to bleed off thus slowing the turbo THUS lowering boost. I was not mistaken or wrong in my statement at all. Hell the simplest way to verify this is look at the WG table in the AP log. When he is not in boost the WG is at 0%. If your theory was valid then he should be at 20PSI at that point!

Our WG spring is set to 10PSI. If you disconnect the factory Boost Controller then you run WG only and the max PSI you will see is 10PSI. Maybe you are confusing the Boost Controller with the WG. That is the ONLY explanation for your comments as you are 100% wrong on what you think a WG does. A simple 5 second Google on "How does a wastegate controller work" will (or should) prove this to you or anyone else.

Actually I see where your confused. What you are calling a WasteGate Solenoid is actually a Boost Controller Solenoid. When the boost pressure setting is reached (15.6 psi stock), the Solenoid activates the WG Actuator and OPENS the WG to lower boost. However you are still very wrong in saying that 0% is FULL BOOST and 99% is Closed making less boost. Sorry man.

Last edited:

Unless I'm TOTALLY misunderstanding your point, you need to do a bit of reading before you come into a forum and tell people they are wrong friend.

Yes, you are TOTALLY misunderstanding my point.

You keep talking about the mechanical wastegate.

I am talking about the Wastegate Control Solenoid Valve (taken directly from the factory service manual).

Recall my first post in this thread: "The log is showing wastegate solenoid valve duty of >90% (and sometimes maxed out) at >5000 RPM.

A higher numerical value = more boost."

That is a statement of fact. Note that I mentioned the "wastegate solenoid valve" and not the wastegate itself.

Anyway, it's very simple:

1) The numbers from OP's log refer to the duty cycle of the electric current applied to the Wastegate Control Solenoid Valve and reflect the amount of the valve opening. The ECU obviously cannot monitor the opening of the actual (mechanical) wastegate itself.

2) Referring to the duty cycle of the Wastegate Control Solenoid Valve, a higher numerical value is telling you that the ECU is trying to increase the boost pressure (greater value = more boost).

Actually I see where your confused. What you are calling a WasteGate Solenoid is actually a Boost Controller Solenoid.

1) I said "wastegate solenoid valve".

2) Where does "Boost Controller Solenoid" come from? That's not what Mazda calls it.

However you are still very wrong in saying that 0% is FULL BOOST and 99% is Closed making less boost. Sorry man.

Did I really say that or did you misread something that I wrote? Please quote me.

To avoid future misunderstandings, it's better to actually read someone's post before replying to it.

Ok I did a bit more research and I understand what you are saying and I apologize for my misunderstanding.

What Matsuda is trying to say is this; The higher number Duty Cycle is the amount of air being bleed off so the actuator does not activate in order to keep the WG from opening. Thus 99% means all air is being diverted from the actuator and the WG is fully closed with max ability to build boost.

Again, my apologies to MY not understanding what you were trying to say.

What Matsuda is trying to say is this; The higher number Duty Cycle is the amount of air being bleed off so the actuator does not activate in order to keep the WG from opening. Thus 99% means all air is being diverted from the actuator and the WG is fully closed with max ability to build boost.

Again, my apologies to MY not understanding what you were trying to say.

Last edited:

- :

- 2007 MS3

2) Referring to the duty cycle of the Wastegate Control Solenoid Valve, a higher numerical value is telling you that the ECU is trying to increase the boost pressure (greater value = more boost).

This is where the confusion came in. I think most of us were of the, apparently mistaken, belief that a greater value meant that it was trying to open the wastegate, which would bleed off boost. Thus higher numbers would indicate that the ecu thought boost was too high and was trying to bring it down.

If the higher numbers in fact mean that it is keeping the gate closed trying to build boost, then the high numbers would indicate instead that the turbo is having trouble reaching the boost set point and the ecu is holding the gate closed trying to reach the target.

Edit: I give up. The more I read about how this system is supposed to work, the more I realize that I don`t really understand what`s going on with it.

In the turbo itself, is the exhaust pressure trying to open the gate or close it? My understanding so far is that the exhaust pressure is trying to open the gate. The wastegate actuator has a spring in it that holds the gate closed normally. With no assistance from boost pressure on the actuator`s diaphragm, the exhaust gasses will force the wastegate open once the spring pressure is surpassed (7-10 psi). Here`s where it gets puzzling. I guess I don`t properly understand the internal plumbing of the actuator and solenoid, because I can`t ken how the boost pressure is regulated after this.

Can somebody please clarify this for me?

Last edited:

Ok I did a bit more research and I understand what you are saying and I apologize for my misunderstanding.

What Matsuda is trying to say is this; The higher number Duty Cycle is the amount of air being bleed off so the actuator does not activate in order to keep the WG from opening. Thus 99% means all air is being diverted from the actuator and the WG is fully closed with max ability to build boost.

Again, my apologies to MY not understanding what you were trying to say.

No problemo and thanks.

This is where the confusion came in. I think most of us were of the, apparently mistaken, belief that a greater value meant that it was trying to open the wastegate, which would bleed off boost. Thus higher numbers would indicate that the ecu thought boost was too high and was trying to bring it down.

If the higher numbers in fact mean that it is keeping the gate closed trying to build boost, then the high numbers would indicate instead that the turbo is having trouble reaching the boost set point and the ecu is holding the gate closed trying to reach the target.?

Yes, the numbers would indicate that the (small) turbo is just about "maxed out" at high RPM's (>5000) and a high boost target (17.5 according to the log).

Edit: I give up. The more I read about how this system is supposed to work, the more I realize that I don`t really understand what`s going on with it.

In the turbo itself, is the exhaust pressure trying to open the gate or close it? My understanding so far is that the exhaust pressure is trying to open the gate. The wastegate actuator has a spring in it that holds the gate closed normally. With no assistance from boost pressure on the actuator`s diaphragm, the exhaust gasses will force the wastegate open once the spring pressure is surpassed (7-10 psi). Here`s where it gets puzzling. I guess I don`t properly understand the internal plumbing of the actuator and solenoid, because I can`t ken how the boost pressure is regulated after this.

Can somebody please clarify this for me?

Think about it this way: It is the wastegate actuator that is actually opening and closing the wastegate.

The ECU/solenoid control valve can control the amount of pressure in the wastegate actuator (and thus control the wastegate opening).

The ECU monitors the boost pressure (with the MAP sensor) and controls the wastegate to maintain the target boost pressure.

- :

- 2007 MS3

Think about it this way: It is the wastegate actuator that is actually opening and closing the wastegate.

The ECU/solenoid control valve can control the amount of pressure in the wastegate actuator (and thus control the wastegate opening).

The ECU monitors the boost pressure (with the MAP sensor) and controls the wastegate to maintain the target boost pressure.

Thank you for the reply, but this much I understand. What I want to know is what is going on inside the actuator and solenoid. How is the boost pressure actually regulated?

I`m the guy who at four tore apart his sister`s stuffed animal to see what made the music come out of it. Then at seven took apart the wind up music box to see what was inside that and how it worked. I like to know what is really happening.

Someone posted a link to the shop manual. I`ll have to spend some time going through it.

Last edited:

- :

- 2007 MS3

Okay, I`ve got it, or at least most of it. Still not 100% sure about one thing.

The wastegate is held closed by spring pressure in the actuator. There is a boost reference on the turbo housing. It is plumbed to the actuator then, through a common fitting, to the solenoid. The solenoid is normally closed, which allows boost to build against the actuator and push the gate open.

When the solenoid is active (duty cycle above zero), the boost reference is allowed to vent through the solenoid to the intake tube, which means the gate stays closed, allowing boost to build.

I`m a little unsure about one thing. I have this notion that the exhaust pressure is pushing against the wastegate, trying to open it. Is this correct or is the length of the wastegate lever sufficient mechanical advantage to keep this under control, thereby taking exhaust pressure out of the equation? If this is the case, then I finally have this figured out. If not, and exhaust pressure has to be accounted for, then I still need to figure out how boost can get higher than 7-10 psi.

Sorry about the threadjack, but this is bugging me.

The wastegate is held closed by spring pressure in the actuator. There is a boost reference on the turbo housing. It is plumbed to the actuator then, through a common fitting, to the solenoid. The solenoid is normally closed, which allows boost to build against the actuator and push the gate open.

When the solenoid is active (duty cycle above zero), the boost reference is allowed to vent through the solenoid to the intake tube, which means the gate stays closed, allowing boost to build.

I`m a little unsure about one thing. I have this notion that the exhaust pressure is pushing against the wastegate, trying to open it. Is this correct or is the length of the wastegate lever sufficient mechanical advantage to keep this under control, thereby taking exhaust pressure out of the equation? If this is the case, then I finally have this figured out. If not, and exhaust pressure has to be accounted for, then I still need to figure out how boost can get higher than 7-10 psi.

Sorry about the threadjack, but this is bugging me.

Well I did couple hard pulls latly after breaking in the stage 1 sf map...and the highest knock I get is 0.7...pretty consistent too..each pull I do it doesnt go higher than 0.7.....so thats alot better than the 4.9-5 knock iwas getting with stage 2 map..as it looks like this map will be the safe map to run till i get my downpipe installed then ofcourse its custom tune after that

Cataphract_40

Knock Retard

- :

- 2008 Mazdaspeed3

Looking through his data, it occurs to me that not once did he go WOT. The closest he gets is 75.27% throttle.

- :

- 2003.5 MSP

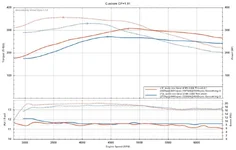

Throttle position never goes past 75% for me when i do WOT runs and i have been doing a bunch of datalogs i know my foot is to the floor and ive been working with Dizzy Tuning for a custom map for my current setup. i believe the accel. pedal position shows if you have your foot mashed to the floor, that logs at 99% when i got WOT. so i think he is doing it right. i posted a Virtual Dyno Graph to show my progress, car is really dialed in right now, feels great. still tweaking the timing, waste gate duty cycle and the load tables but i should be done soon.

Attachments

New Posts and Comments

- Replies

- 56

- Views

- 40K

- Replies

- 10K

- Views

- 3M