Had some time to waste tonight, and I didn't feel like working. I re-ran the sway bar models, I wasn't happy with the constraint settings I used the first time, I think they were too restrictive (the program I use is feature limited, so I have a more limited selection. Hey, it was cheaper than the full-on version). I also updated the AWR bars to be hollow, with a 0.20" wall thickness. My model also assumes the RB bar is NOT hollow.

This is what I got for the rear bars:

Stock RB - 238 lb/in

AWR with "long" settings - 161 lb/in (SOFTER than stock RB)

AWR with "short" settings (about same distance as RB) - 384 lb/in

RB "klunked" - 660 lb/in

I was surprised by the last one, the bending of the bar to get to the stock mounting point takes alot out of the bar. The RB klunked number isn't really true, since the it will deflect the bushings more and I didn't (couldn't) account for that.

Also, I can't account for bushing deflection at all, but it will have an affect. I think it would be worse on stock mounting points versus klunk-fixed, since the effect of the deflection is "magnified" by the lever arm length. In general, though, "actual" rates measured at the wheels will definitely be lower.

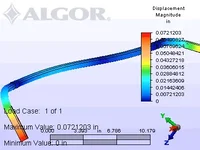

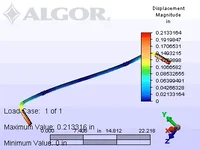

The two pics I've attached are from the RB simulation, both the stock and the Klunked setups.

From what I see, the RB bar with the klunk fix is the better setup. I've got an RB bar & the klunk fix in the garage, I'll be changing back soon. I just can't take the noise of the AWR setup, and it appears there's no other benefits..