Jesus christ dude.

Do you need $25 for an aftermarket mount? I'll gladly paypal you some money.

Per suggestion of another forum member, I bought

https://www.amazon.com (commissions earned) set of mounts. I've replaced the passenger and transmission side mount. Aaaalmost got the front mount done, but my friend striped the nut holding the bolt that connects the engine to the mount so I'm waiting to pick up a replacement nut before I tackle that one. I'm also going to order an OEM rear mount since I don't want to ever replace that one as long as I own the vehicle. I think I may pay someone to do it for me.

Be really careful with E-Bay for parts,... the passenger side mount is different for the manual and auto tranny and a lot of parts dealers don't know this.

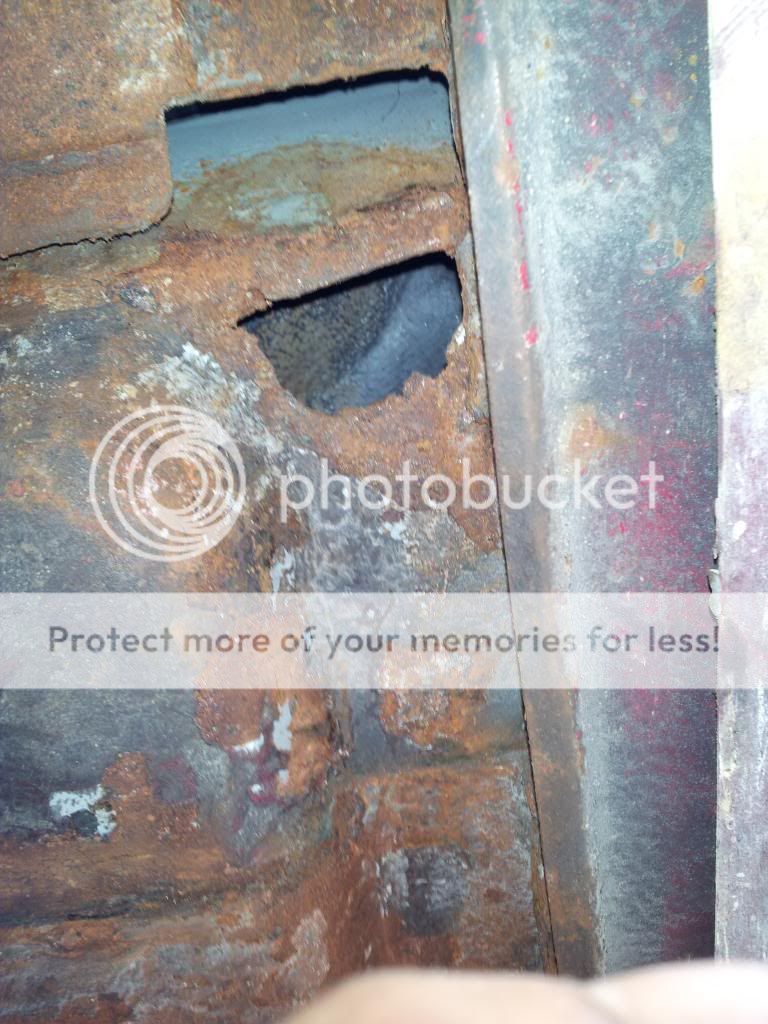

Here's a picture of what's involved with replacing a rear engine mount,... cutting away parts or your car is part of the process...

There is no SST for this job. (but I think this tool may help),...

It's not about the money for that particular part for me and my car,... it's about the total cost of keeping my car on the road until my ass falls through the floorboards.

Remember this is Canada,.. I've had my car since April 2009 and since then have seen at least 100 P5's on the road. Of all of those cars, I've only seen 3 or 4 that were in as good a condition as mine. (I always check the rear fender for rot when I pass one (as well as check for the side marker light to know if it's a 2002 or 2003))

As far as my front engine mount goes,.. This is a picture of it.

The big-ass (apparently there's a hyphen for that word) bolt that goes through it has a big square end on it that is supported by that little metal tab on the frame mounted part of the mount.

I know almost for a fact that when I reef on the nut on the other end of the bolt that the tab is going to break off (due to the rust eating it away as well as the rust fusing the nut to the other end of the bolt)

So,... then out comes the huge vise grips or adjustable wrench (which will keep falling off) to hold the square end while I try to apply about 400 foot pounds of torque to it without cracking my head open.

Then out come the saws-all then when that doesn't work, the cutting torch. And I can't cut or melt any of the frame mounted parts while removing the bolt.

Then I wait for a new OEM bolt and nut to come in the mail cause now I can't drive to the dealership for a new one.

So,... I'm not replacing my engine mounts until the engine itself is smacking the back side of my hood.

However ,... It was late fall when I jammed that piece of rubber in there and I do intend to replace it with window weld when the snow melts but I'm not even going to consider removing them to do it.

So,... as you can see your $25 donation doesn't go very far, but I am willing to trade cars with you,... we can meet at the border, exchange cars and we'll both be happy. You will get the chance to learn all about the things that aren't covered in the FSM.

Here's my suggestion for you: buy an engine support beam. The official mazda workshop manual even says to use it for that. The use is a bit limited, but you can always sell it to someone if you're sure you'll never use it again.

This one on harbor freight occasionally goes on sale for $50. I used a friend's engine hoist to hold everything in place and it made life fantastically easy -- much easier than if we'd used a jack and a piece of wood.

A lot of mechanics don't even have that tool (except the ones at the Mazda dealerships). There's always a relatively easy way to work without it.

I think the OP needs more basic tools,.. breaker bar, quality deep sockets, wrenches and even the big-ass vice grips (which end up being used more than we'd all like to admit)

With all that being said, I still love my car,.. even with her fourth stage cancer.

When I went out to start my car that hadn't been started for 2 1/2 weeks and it was -23 *C (-10 *F) and it started up, that is my idea of success.

She's not dead yet.