Jeff@Tri-Point

Member

Protege 5 FSB & MSP RSB Rates

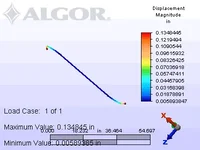

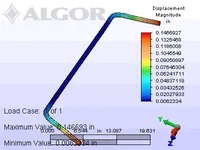

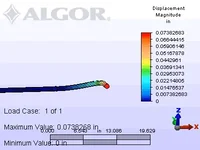

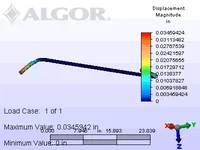

Co Worker helped me measure the sway bar rates on the Protege 5 FSB and MSP RSB

Protege 5 Front Sway Bar -120lbs/inch

MSP Front Sway bar maybe 142lbs/inch ~ figure 18.5% Increase

MSP Rear Sway Bar - 144lbs/inch

A little weak? (boom07)

Co Worker helped me measure the sway bar rates on the Protege 5 FSB and MSP RSB

Protege 5 Front Sway Bar -120lbs/inch

MSP Front Sway bar maybe 142lbs/inch ~ figure 18.5% Increase

MSP Rear Sway Bar - 144lbs/inch

A little weak? (boom07)

Last edited: