I wrote this up a while ago, but haven't posted it due to the differing opinions on this problem. I'm going to post it anyways for the informational bennefits about the turbo in this car. I am not convinced though that it is a pressure differential issue, yet....

I have done some reading on this turbo and found some good info.

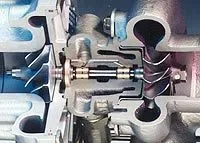

The bearings on this turbo are brass sleeves over the turbo shaft. These brass sleeves turn independently of the turbo shaft at about half the speed of the shafy because they are floating on engine oil that flows on the inside of the sleeves and the outside of the sleeves. Clearances are a few hundreths of a milimeter. They claim this is the most efficient way to get RPMs up to 300,000 and life-span to 621K miles in commercial vehicles. I'm assuming a low boost in that application!

Anyways, looking over the deisgn of this turbo, it is clear to me why they can leak oil into the exhaust. Here is a description of the The axial-thrust bearing"

"As the gas forces acting on the compressor and turbine wheels in axial direction are of differing strengths, the shaft and turbine wheel assembly is displaced in an axial direction. The axial bearing, a sliding surface bearing with tapered lands, absorbs these forces. Two small discs fixed on the shaft serve as contact surfaces. The axial bearing is fixed in the centre housing. An oil-deflecting plate prevents the oil from entering the shaft sealing area."

Lowering the back pressure and increasing boost or using a quicker BPV will introduce more dramatic axial movement in the turbo shaft everyting you let off the gas. I think this can increase wear on the axial bearings.

Also, here is another quote about the sealing of the turbo:

"The centre housing must be sealed against the hot turbine exhaust gas and against oil loss from the centre housing. A piston ring is installed in a groove on the rotor shaft on both the turbine and compressor side. These rings do not rotate, but are firmly clamped in the centre housing. This contactless type of sealing, a form of labyrinth seal, makes oil leakage more difficult due to multiple flow reversals, and ensures that only small quantities of exhaust gas escape into the crankcase."

So, if there is a chance that exhaust gas can escape into the crank-case, then there is a chance that oil can escape into the exhaust under certain pressure differential conditions (idling or just after WOT seems most probable).

Read this about turbos and oil:

"The bearings are usually destroyed by either oil contamination, oil starvation or oil coking.

If the inside of the bearing housing resembles the bottom of a frying pan and is coated with black crusty deposits, oil coking was the cause of failure. The bearings are oil cooled, and during normal operation temperatures don't get hot enough to cause oil coking. But when the engine is shut off, temperatures can rise to 600 to 700 degrees F. inside the housing as the turbo undergoes a period of heat soak. The oil oxidizes and forms coke deposits in the housing that then act like an abrasive to wear the bearings. Using a high temperature "turbo" oil or synthetic oil, installing an auxiliary oil cooler, and changing the oil every 3,000 miles can avoid oil breakdown and coking problems. In water-cooled turbos, coking is less of a problem provided the oil is changed regularly and you use a quality motor oil."

Below, I have highlighted what I believe are contributors to oil leaking into the exhaust from the turbo:

1. Engine oil not clean and fresh and not of a type stable at High operating temperatures.

2. Turning off the engine while the turbo is still hot and/or spinning.

3. Not letting the engine oil warm up and flow into the turbo before driving.

4. Pressure changes between the inlet side and exhaust side of the turbo