digitalpro5

Member

- :

- 2003 Blackmica Protege5

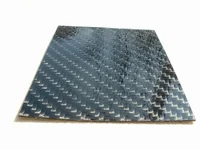

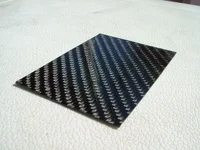

I got these samples from carper4mance.com a couple days ago and wanted to show you guys that haven't seen it yet what they look like. In my oppinion they look really cool, and I would get some as soon as I have some off time to do some interior mods.

Pros:

They look cool.

3M Hi performance adhesive (I don't know really just what it sais behind the sheet)

Thickness is good for not to complicated things.

Cons:

The sample I got had imperfections in the resin (the clear top) that the digital camera can pick up. Mainly scratches that look to be imbeded in the resin. Other then the camera picking it up, my eye can't.

To thick if you trying to bend it into a cylinder shape (I was thinking of doing my ebrake but it probably would have fallen off (unless that adhessive is really strong).

Anyways thats my oppinion.

Pros:

They look cool.

3M Hi performance adhesive (I don't know really just what it sais behind the sheet)

Thickness is good for not to complicated things.

Cons:

The sample I got had imperfections in the resin (the clear top) that the digital camera can pick up. Mainly scratches that look to be imbeded in the resin. Other then the camera picking it up, my eye can't.

To thick if you trying to bend it into a cylinder shape (I was thinking of doing my ebrake but it probably would have fallen off (unless that adhessive is really strong).

Anyways thats my oppinion.