autobodydesign

Member

We're dealing with plastic and urethane parts. Things you might find in a mfr catalog, or you might see as some sort of special edition on a newer car.

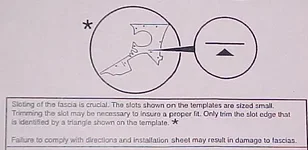

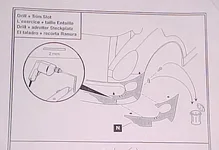

Here is part of a ground effects package we manufacture. It is a left

front fascia extension, and fits below the bumper. Nice looking partif I say so myself...

Here is part of a ground effects package we manufacture. It is a left

front fascia extension, and fits below the bumper. Nice looking partif I say so myself...