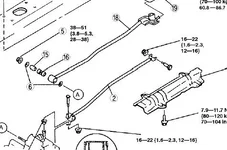

I have been purusing a few threads here and. I am tempted to purchase a shift fork (the one that a few people seem to be breaking), mic it out (i.e. obtain precise dimensions) and machine a new out off high alloy stainless steel and determine a decent heat treat value to anneal it to.

Basically, reverse engineer it and improve on it. I'm surprised that B&M or Karboy (*wink, wink*) hasn't designed and produced such an "upgrade". I just want to make it in a manner that I won't have to ever worry about it....I understand the principles of driver error, etc in the failures that HAVE occured. I think something along these lines might benefit those that are generating more power and or want more reliable shifts.

Some questions:

1) Does anyone happen to know off hand what the cost of JUST the fork (shaft, rod?) is? I'll bother the dealer tommorrow...

2) Has anyone seen one of these break/broken? Is it cast iron or aluminum or what? Just wondering about the material.

3) Installation/removal. Is this possible to do on one's own or is the dealer/competent shop?

Thanks....any ideas or discussion to the matter at hand would be good too.

Basically, reverse engineer it and improve on it. I'm surprised that B&M or Karboy (*wink, wink*) hasn't designed and produced such an "upgrade". I just want to make it in a manner that I won't have to ever worry about it....I understand the principles of driver error, etc in the failures that HAVE occured. I think something along these lines might benefit those that are generating more power and or want more reliable shifts.

Some questions:

1) Does anyone happen to know off hand what the cost of JUST the fork (shaft, rod?) is? I'll bother the dealer tommorrow...

2) Has anyone seen one of these break/broken? Is it cast iron or aluminum or what? Just wondering about the material.

3) Installation/removal. Is this possible to do on one's own or is the dealer/competent shop?

Thanks....any ideas or discussion to the matter at hand would be good too.

Last edited: