Digbicks1234

16.5 CX-5 Touring/2023 CX-9 Touring

Hey guys,

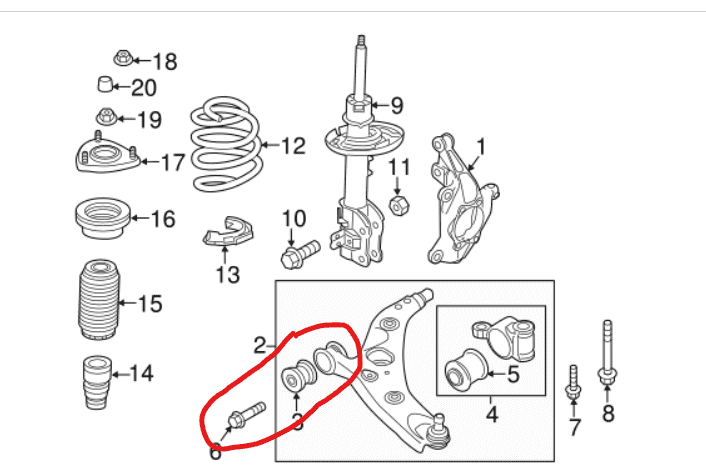

I finished replacing majority of the components for my front suspension and when I was doing a test drive last night, I kept hearing clunks over uneven pavement/bumpy roads for the driver (front) side. The clunking noise is audible around <20 mph but if I go around 30-40 mph, it seems to not be as pronounced. I went through every single bolt that I touched twice with the torque wrench and followed the factory torque spec ranges within the service manual. The only thing that I can think of after doing more research is the below:

Parts Replaced (OEM with exception of Front Struts)

Parts that I attempted to replace:

https://soundcloud.com/user9598857/...d&utm_medium=text&utm_campaign=social_sharing

I finished replacing majority of the components for my front suspension and when I was doing a test drive last night, I kept hearing clunks over uneven pavement/bumpy roads for the driver (front) side. The clunking noise is audible around <20 mph but if I go around 30-40 mph, it seems to not be as pronounced. I went through every single bolt that I touched twice with the torque wrench and followed the factory torque spec ranges within the service manual. The only thing that I can think of after doing more research is the below:

- I messed up the install somehow/forgot to tighten something down.

- Center top nut holding down the entire suspension assembly to be tightened.

- Front Struts Damaged? I did see an indentation from some of the strut nuts puncturing the box when it arrived, not sure if it has to do with that.

- Strut Mounting Plates: Since this is a pre-assembled strut from KYB, I am not sure if it is possible but there may be a defect.

- Control arms need to be in a specific position? Not sure how true that is but I lined up all of the bolt holes and hand tightened everything before tightening it down with a ratchet/torque wrench.

- Possibly the knuckle?

- Lower Control Arm Bolt: There was one bolt that feeds into the horizontally into the Engine Cradle I believe and it was blocked by the transmission pan so I had to use a 19 mm swivel head bolt with an extension to get into there with the torque wrench and tighten it down to 170 ft. lbs. I did it a second time just to be safe but I am not sure if this may have something to do with the noise.

Parts Replaced (OEM with exception of Front Struts)

- Front Struts: Used KYB

- Front Tie Rods: Used OEM

- Stabilizer End Links: Used OEM

- Stabilizer Link Dampers: Used OEM

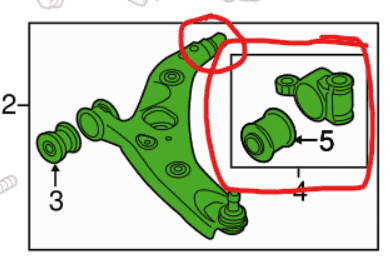

- Lower Control Arms: I replaced both sides with OEM lower control arms and I believe I saw some play in one of the sides but it might be normal. Please see the side circled in red as that may be the side.

Parts that I attempted to replace:

- Front Stabilizer Bar Bushings: I originally planned to remove the front stabilizer bar bushings but it was getting really late and I ended up slightly rounding one of the bolts holding the stabilizer bar bushing brackets before stopping. It did not seem to come loose.

https://soundcloud.com/user9598857/...d&utm_medium=text&utm_campaign=social_sharing

Last edited: