- :

- 2003.5 MSP

Water/meth system installed. I'm not totally happy with the pump and tank location but it will do for now. Protected lines with that fancy expandable loom and routed underneath car along side the fuel lines.

Mounted the water injection valve on backside of cold air box and injector nozzle on cold

side pipe near intercooler exit.

Control board is mounted in the glove box. It has a case but it's off right now so I can swap jumpers around to test the system before driving and make sure water is actually spraying.

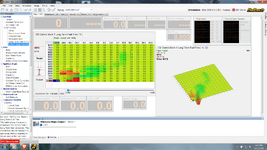

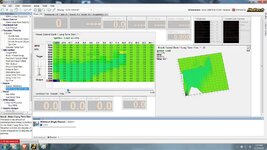

System is wired to the haltech so it will trigger 2 different fuel/boost/ignition maps. One for high boost/water injection and one for low boost/conservative timing in case the system is turned off, water level goes low or there's a flow fault. The way it works is the aquamist will send a 5 volt signal when powered up to tell the haltech everything's good, enable high boost. If there's a fault or the gauge is turned off, the aquamist sends a 0 volt signal to the haltech and it automatically reverts to the safe map.

Had to ditch my wideband cause I didn't have an extra pod. Haltech's taking care of o2 control anyways so it was an easy kill.

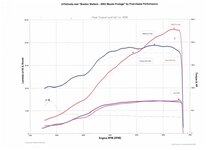

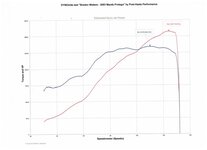

Boost controller re-located, now it's time for the dyno!

Mounted the water injection valve on backside of cold air box and injector nozzle on cold

side pipe near intercooler exit.

Control board is mounted in the glove box. It has a case but it's off right now so I can swap jumpers around to test the system before driving and make sure water is actually spraying.

System is wired to the haltech so it will trigger 2 different fuel/boost/ignition maps. One for high boost/water injection and one for low boost/conservative timing in case the system is turned off, water level goes low or there's a flow fault. The way it works is the aquamist will send a 5 volt signal when powered up to tell the haltech everything's good, enable high boost. If there's a fault or the gauge is turned off, the aquamist sends a 0 volt signal to the haltech and it automatically reverts to the safe map.

Had to ditch my wideband cause I didn't have an extra pod. Haltech's taking care of o2 control anyways so it was an easy kill.

Boost controller re-located, now it's time for the dyno!

Last edited: